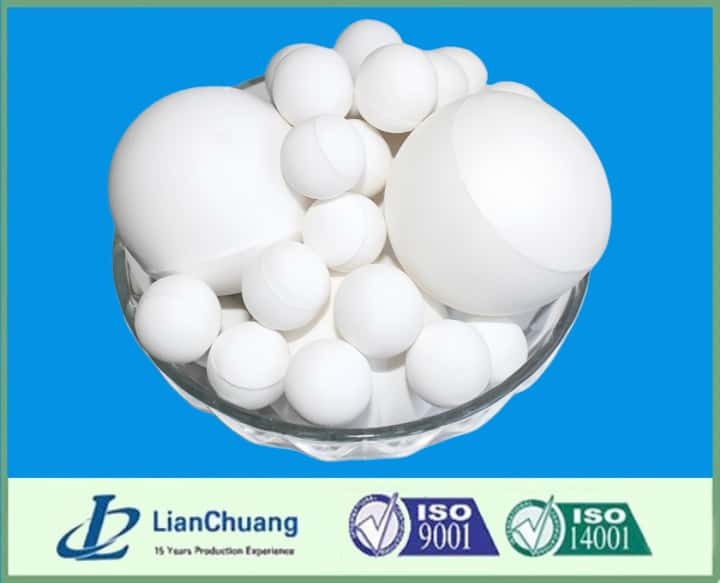

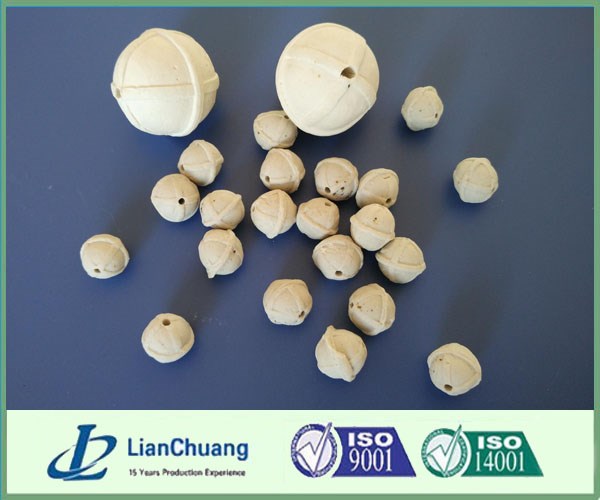

Product Description

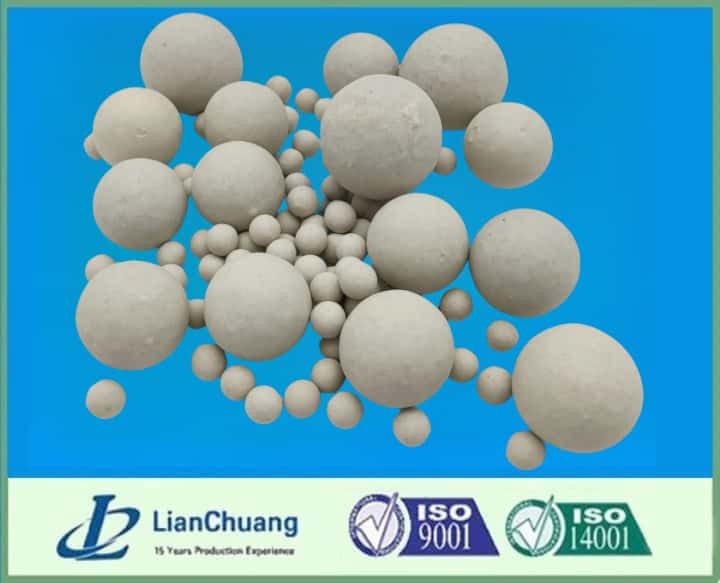

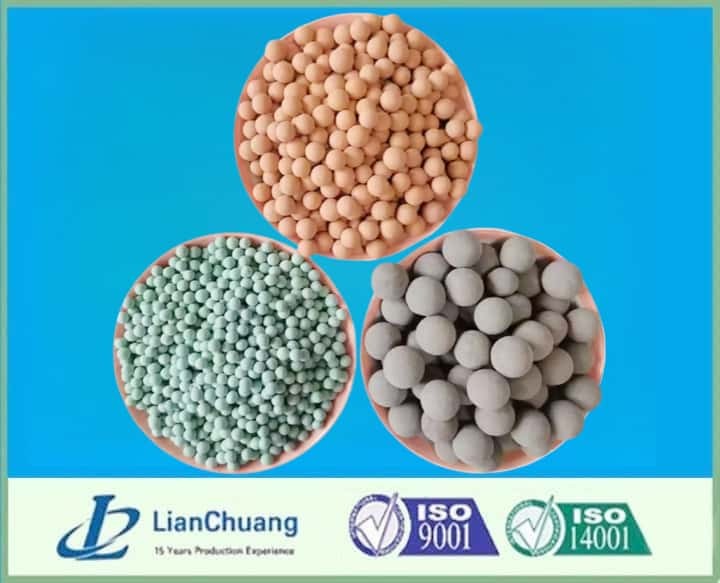

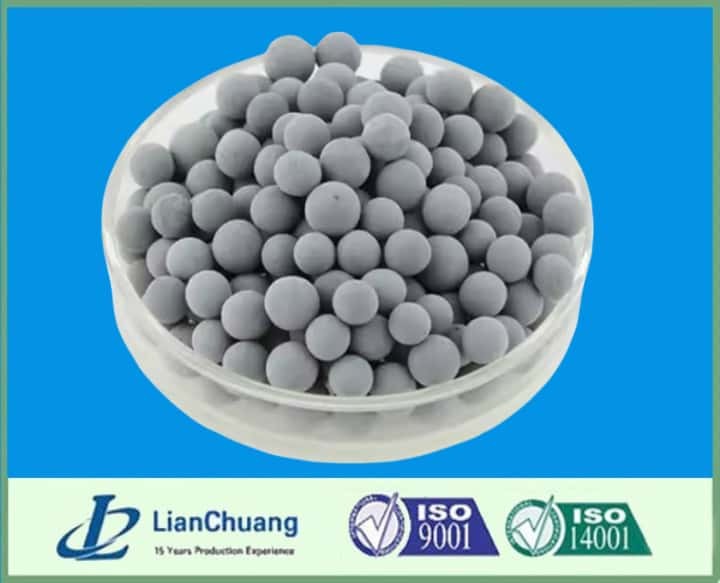

Heat storage ceramic balls are characterized by its high strength, low abrasion loss, large heat capacity and thermal conductivity result in efficient heat storage performance, excellent resistance to high temperature and the thermal shock. heat storage ceramic ball has good thermal stability, big heat capacity, excellent thermal conductivity, high regenerative efficiency, extreme changes in temperature without cracking, strong slag resistance, high strength, good wear resistance and other advantages.

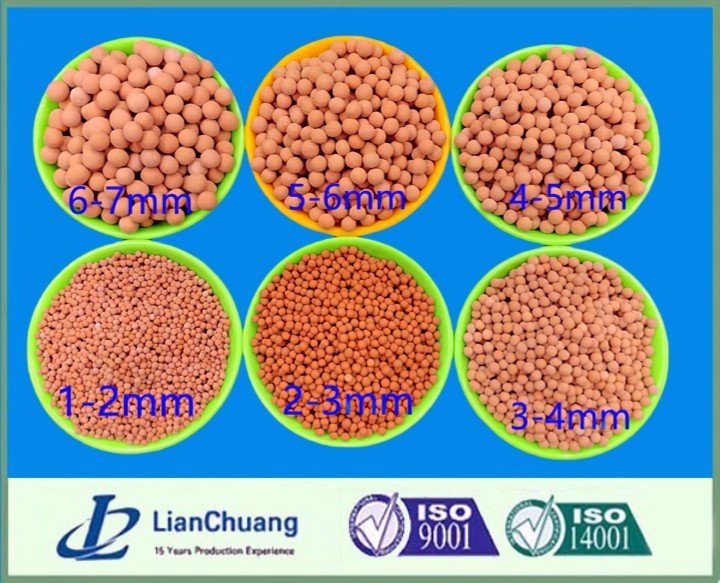

Mass small heat storage ceramic balls divide airflow into small flow.When airflow pass through in heating storage ball,disordered flow is formed.It bursts boundary layer of storage ball.Because of small diameter of ball,small conductive diameter,small heating block,high density,good conductivity.The requirement that heating storage type burner commute frequently and speedily can come true.

Characters of heat storage ceramic ball:

1. The high efficiency heating storage ball produced by LianChuang company,its surface area can reach 240m2/m3

2. Heat accumulator make use of 20~30 times/h commutation,after the high temperature smoke flow trough bed layer of heat accumulator,the smoke flow falling to 130 C is discharged.

3. The heating storge ball have strong oxidation resistance and slag-resistane ect.

4. The exchange and cleanout of ceramic ball is very convenient, it can be used repeatly.

5. In the same pathway,the high temperature coal gas and airflow through heat accumulator can warm up respectively to lower by about 100 C than temperature of smoke gas.The efficiency of temperature can reach more than 90%.

6. The volume of heat accumulator is very smart and the circulating ability of ball bed is strong,so it will not influence heating exchange index even if resistance increase after ash deposition.

Technical Specification

Type | LC-XR-1 | LC-XR-2 | |

% | Al2O3 | 20-30 | 60-65 |

Chemical composition | SiO2+Al2O3 | ≥90 | ≥90 |

% | Fe2O3 | ≤1 | ≤1.5 |

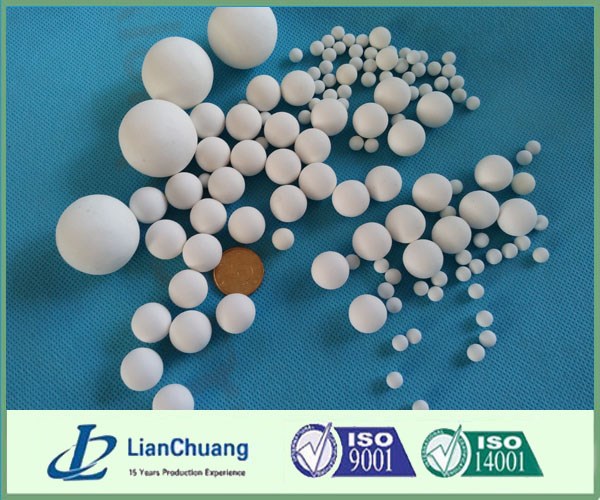

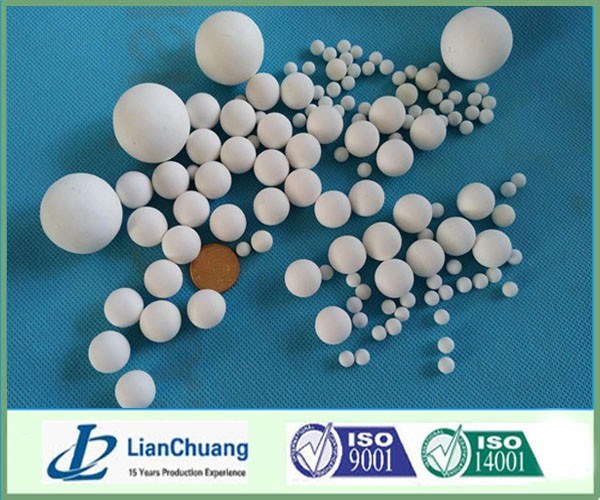

Size,mm | 10-12/12-14 | 16-18/20-25 | |

Heat capacity, J/kg.k | ≥836 | ≥1000 | |

Thermal conductivity,w/m.k | 2.6-2.9 | 2.6-2.9 | |

Thermal shock resistance,°C | 800 | 1000 | |

Refractoriness,°C | 1550 | 1750 | |

Abrasion loss,% | ≤0.1 | ≤0.1 | |

Mohs’ hardness,scal | ≥6.5 | ≥6.5 | |

Crushing strength,N | 800-1200 | 1800-3200 | |

Bulk density,kg/m3 | 1300-1400 | 1500-1600 | |

We promise to reply you in 24hours, OEM & ODM service for your unique idea with absolute convenience. We value our business credit, promise to keep your company information confidential.If any inquiry or problem.Please feel free to contact us.