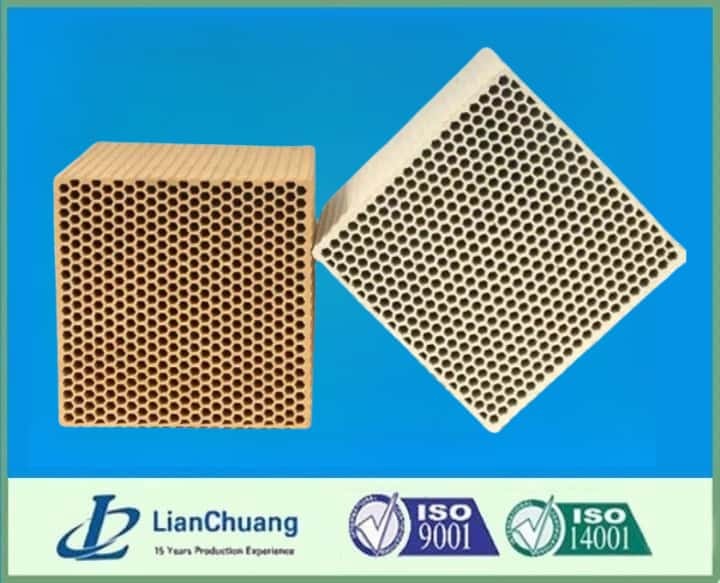

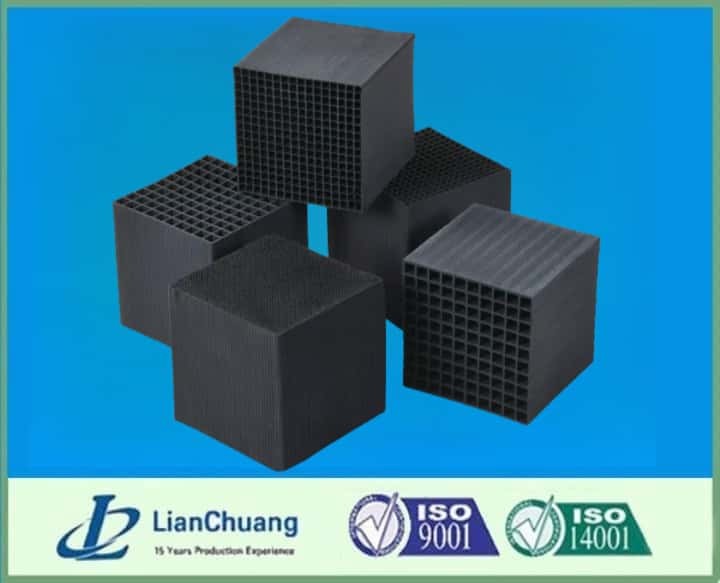

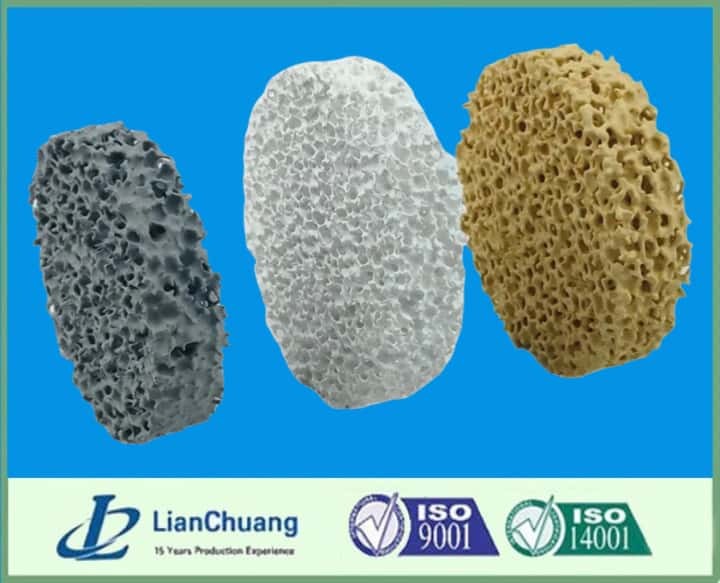

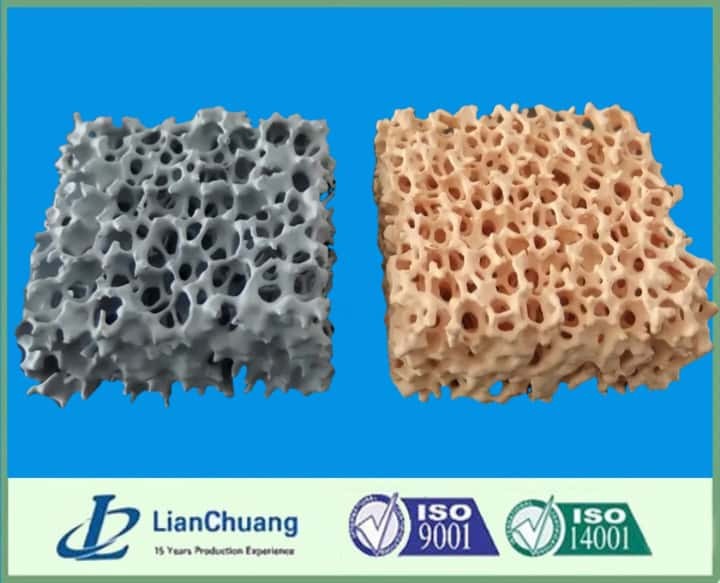

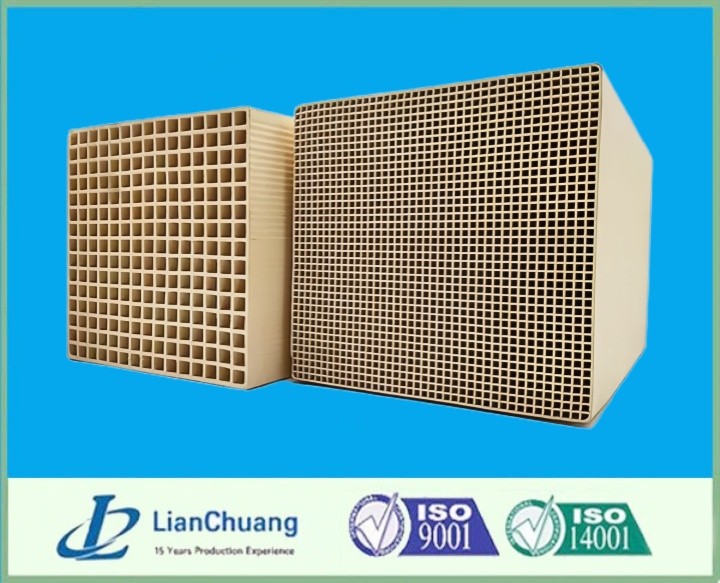

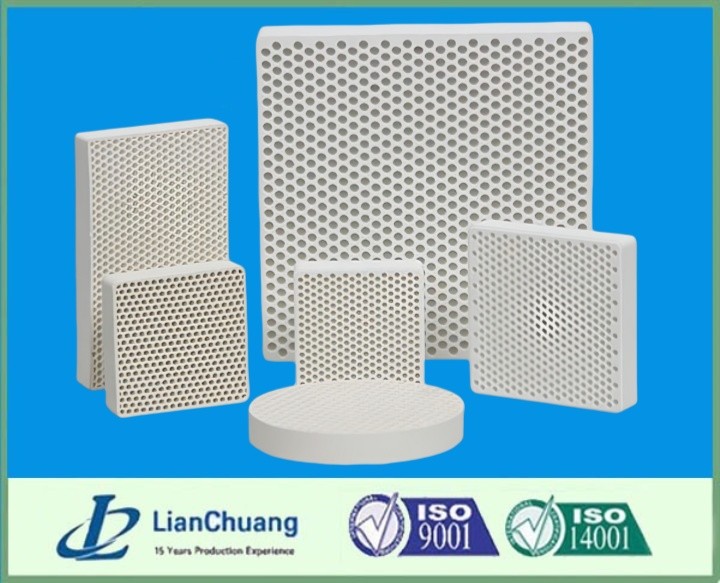

Product Description

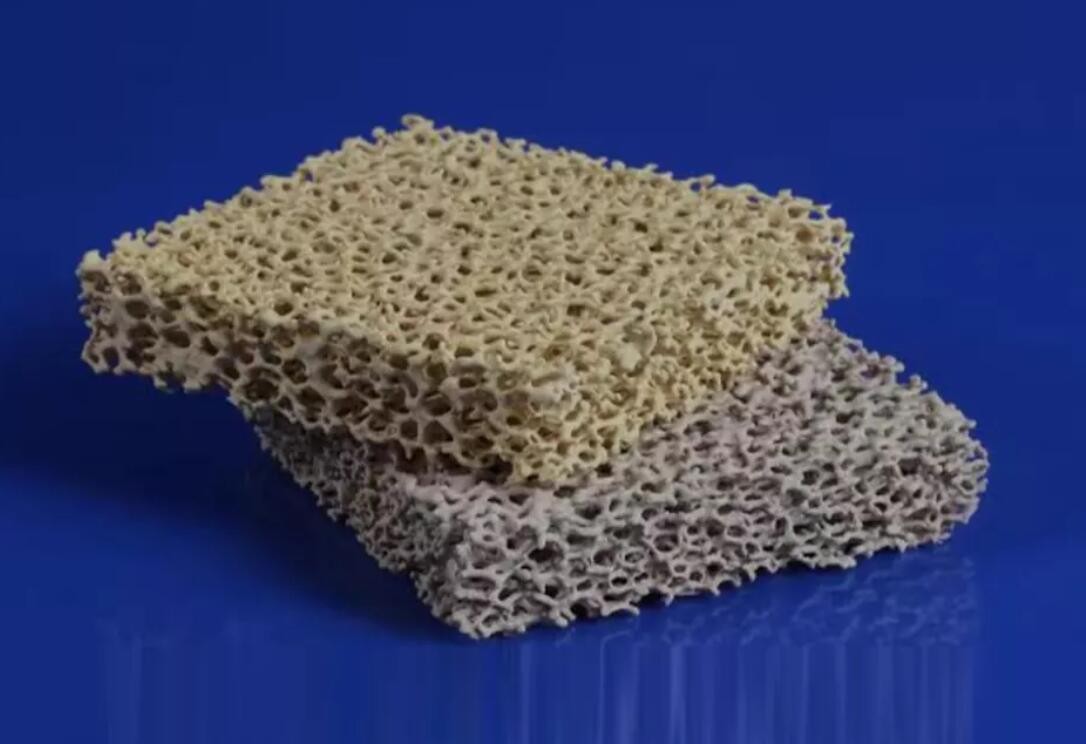

Thermal storage ceramic honeycomb has been developed for many years, with low heat expansion coefficient, large surface area, good heat stability and anticorrosion. ceramic honeycomb has researched and developed a series of thermal storage ceramic honeycombs according to the different features of industrial furnaces, thermal storage ceramic honeycombs could applied to purify industrial waste gas, automobile emissions, eliminate noise, deal with waste water, to dry air, incineration, used in the manufacture of infrared ray instruments, to filter metal liquids etc.

Specification

| Specification (mm) | Quantity of channels | Wall thickness (mm) | Width of channels | Specific Surface Area(m2/m3) | Void (%) | Density (kg/m3) | Weight |

|---|

| 150*150*300 | 25*25 | 1 | 4.96 | 580 | 68 | 696 | 4.7 |

| 150*150*300 | 40*40 | 0.7 | 3.03 | 891 | 65 | 814 | 5.5 |

| 150*150*300 | 50*50 | 0.6 | 2.39 | 1090 | 63 | 903 | 6.1 |

| 150*150*300 | 60*60 | 0.5 | 1.99 | 1303 | 63 | 932 | 6.3 |

| 150*100*100 | 40*40 | 1 | 2.5 | 784 | 49 | 799 | 1.2 |

| 150*100*100 | 33*33 | 1.1 | 3 | 691 | 52 | 750 | 1.13 |

| 150*100*100 | 20*20 | 2 | 5 | 392 | 49 | 692 | 1.04 |

| 100*100*100 | 40*40 | 1 | 2.5 | 784 | 49 | 810 | 0.81 |

| 100*100*100 | 33*33 | 1.1 | 3 | 691 | 52 | 750 | 0.75 |

| 100*100*100 | 20*20 | 2 | 5 | 392 | 49 | 680 | 0.68 |

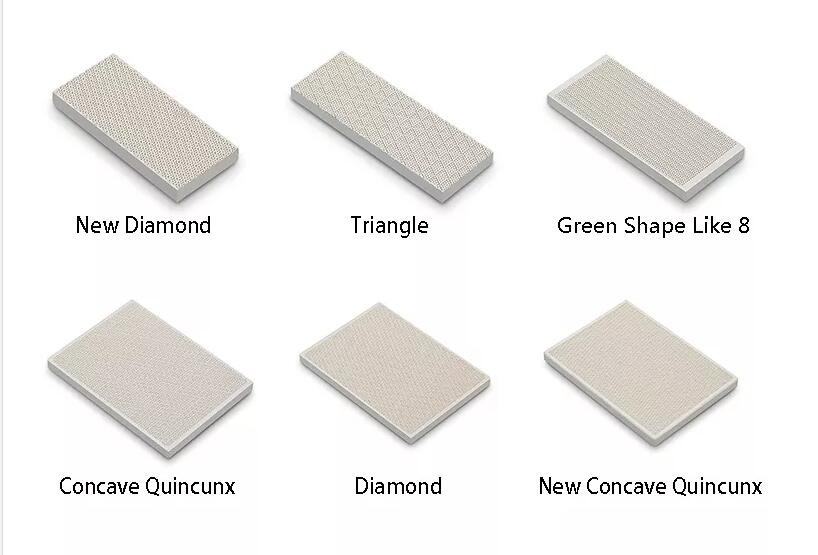

Note: Other thermal storage ceramic honeycomb shapes and specification are also available

Chemical composition (Cordierite):

| Chemical Composition | % |

|---|

| SiO2 | 60 |

| Al2O3 | 33 |

| Fe2O3 | <1 |

| CaO | 1-2 |

| K2O + Na2O | 2-4 |

Physical properties of ceramic honeycombs for thermal storage:

| Index | Value |

|---|

| Cordierite gross density(g/cm3) | 1.9-2.0 |

| Average linear expansion(20-1000) (10-6/k-1) | <2 |

| Specific heat capacity(KJ/Kg) | 830-900 |

| Temperature cycle resistance(K) | 300 |

| Max operation Temp.(Degree C) | 1300 |

| Thermal shock resistance(Degree C) | 800 |

| Acid resistance(%) | >99 |

| Alkali resistance(%) | >85 |

| Water absorption(Wt%) | 22% |