Chemical ceramic balls are an essential component of the chemical industry, serving a pivotal role across diverse industrial operations due to their distinct physical and chemical characteristics. These balls are versatile, functioning as catalyst carriers, abrasives, and support media, thus catering to the modern industry's requirements for materials that are both highly efficient and performative. This article explores the various types of chemical ceramic balls, detailing their unique features, uses, and the China distribution of their production hubs.

Types and Characteristics of Ceramic Balls

In the realm of chemical engineering, ceramic balls play a vital role across various applications, distinguished by their composition and the specific advantages they offer. This article focuses on the classification of chemical ceramic balls, including silicon nitride balls, silicon carbide balls, zirconia balls, inert ceramic balls, and alumina grinding balls, each serving unique purposes in industrial processes.

Silicon Nitride Balls

Silicon nitride balls are prized for their high strength, wear resistance, and thermal stability. These characteristics make them ideal for use in high-speed bearings where high precision and durability are required. Their resistance to thermal shock and low density also make them suitable for applications in harsh environments, including those involving high temperatures and corrosive substances.

Silicon Carbide Balls

Silicon carbide balls offer exceptional hardness, second only to diamond. This makes them excellent for use in applications where high levels of wear resistance and thermal conductivity are necessary. They are commonly utilized in bearings, pumps, and valves that operate in extreme conditions, including high temperatures, corrosive environments, and high loads.

Zirconia Balls

Zirconia balls are known for their high strength and toughness, which is significantly enhanced through the process of transformation toughening. This unique property makes them highly resistant to wear and breakage, ideal for use in high-precision valves, grinding media, and as components in pumps and bearings. Their chemical inertness also makes them suitable for use in environments where chemical resistance is crucial.

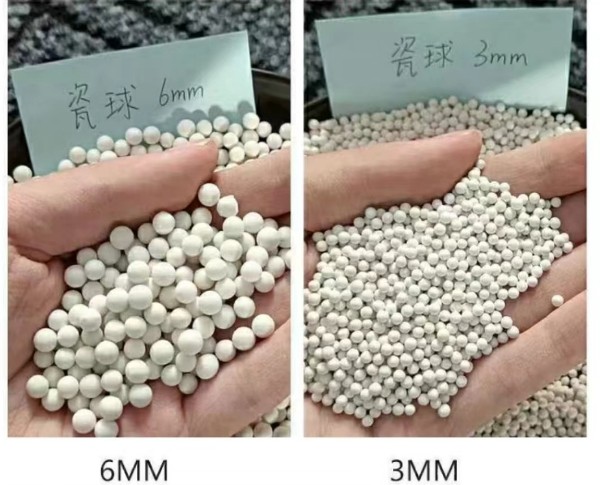

Inert Ceramic Balls

Inert ceramic balls are primarily used as support media in petrochemical and chemical processing. Their main function is to increase the distribution of liquids and gases, improve heat transfer, and protect the active catalyst in reactors. Made from materials like alumina, they are chemically inert, resisting attack from acids, alkalis, and organic solvents.

Alumina Grinding Balls

Alumina grinding balls are specifically designed to optimize the grinding process in industrial milling operations. These balls are made from high-purity alumina oxide, which ensures minimal contamination of the milled product. They are highly efficient in grinding processes, reducing processing time and energy consumption. Alumina grinding balls are widely used in ceramics, paints, refractories, and mineral processing.

China Distribution of the Ceramic Balls Industry

In China, the production of these materials is mainly concentrated in regions with rich raw material resources, a strong industrial base, and good scientific research support. Specifically:

Silicon nitride balls and silicon carbide balls: Mainly concentrated in Shandong, Jiangsu, Henan, Sichuan, and other places, these areas have a more complete silicon material processing industry chain, especially for the production of silicon carbide, because these regions are conducive to the acquisition of raw materials and cost control.

Zirconia balls: Production is mainly concentrated in Jiangxi, Fujian, Sichuan, and other places, which are rich in zircon sand resources and are important bases for the production of zirconium products in China.

Inert porcelain balls: Widely distributed in Jiangxi, Shandong, and other areas, where the ceramic industry is developed, especially in the field of high-performance ceramics, providing good technical and industrial support for the production of inert porcelain balls.

Alumina grinding balls: Mainly distributed in Henan, Shandong, Jiangxi, and other places, these regions have a more developed alumina industry chain. Alumina grinding balls, as important abrasive and grinding materials, are widely used here.

Choose Our Factory As YourPartner in Ceramic Balls Area

In the global chemical processing and grinding materials market, choosing a reputable, experienced supplier is crucial. Our company, located at the heart of China's industrial ceramic ball production belt, specializes in the production and export of chemical packing ceramic balls and alumina grinding balls. With years of industry experience and a strategic location, we provide our global customers with cost-effective, high-quality product solutions.

Cost Advantage - Your Economical Choice

Our factory is situated in a resource-rich industrial belt, ensuring a stable supply of raw materials and significantly reducing production costs. As a result, our chemical packing ceramic balls and alumina grinding balls are offered at highly competitive prices, designed to give you an edge in the fierce market competition.

Quality Assurance - Your Reliable Choice

Quality is one of our core competitive strengths. We utilize advanced production technology and a strict quality control system to ensure that each batch of products meets international standards. Whether it's chemical packing ceramic balls or alumina grinding balls, we promise to deliver the highest quality products to meet your high standards.

Experienced - Your Professional Choice

Over the years, we have focused on the production and export of chemical packing ceramic balls and alumina grinding balls, accumulating rich industry experience and market insights. Our products have been successfully exported to various countries and regions, winning widespread recognition and praise from international customers. Our professional team can provide personalized services to ensure your specific needs are met.

Choosing us means selecting a responsible, experienced partner offering high-value products. Let's work together to create a prosperous future!