Cooling towers are often used in industrial operations, serving the vital function of efficiently dissipating excess heat from various systems. Drift eliminators is one of the main components that enhance the effectiveness of cooling towers is . These devices are applied in minimizing the loss of water droplets and chemicals to the environment, thereby promoting sustainability and resource efficiency. In this article, we will explore the significance of drift eliminators, their operational mechanisms, and the various types commonly utilized in cooling tower applications.

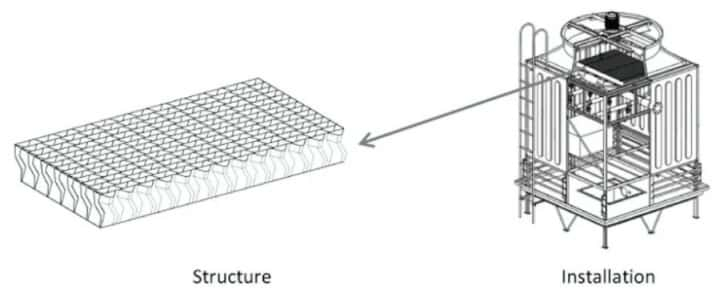

1. Introduction of Cooling Tower PVC Drift Eliminators

Definition of Drift Eliminators

Drift eliminators are specialized devices used in cooling towers and similar systems to capture and separate water droplets from the air before it is released into the atmosphere. Their primary function is to minimize the loss of water and chemicals carried away by escaping air, a phenomenon known as "drift." By doing so, drift eliminators enhance the efficiency of cooling processes, reduce water wastage, and mitigate potential environmental impacts caused by chemical discharge.

PVC Drift Eliminator's Importance in cooling tower operations

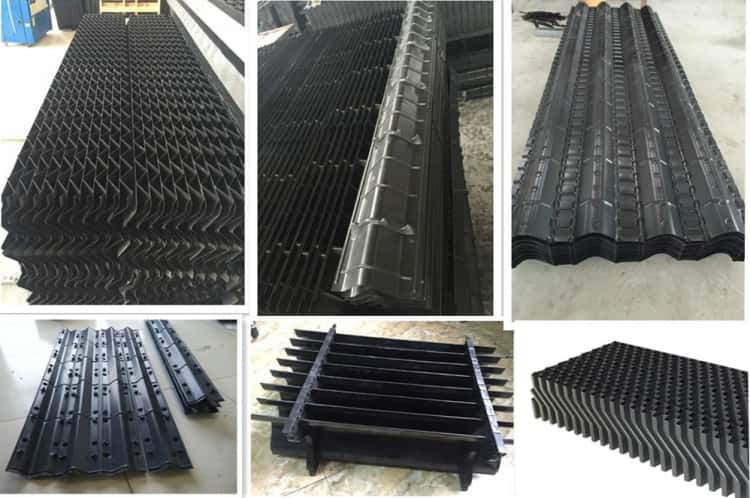

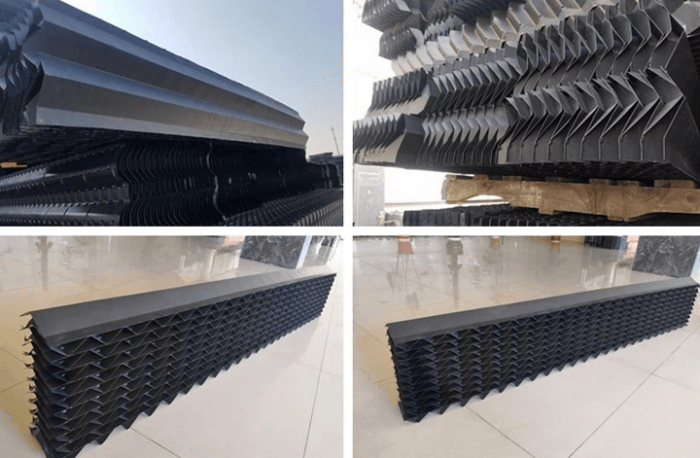

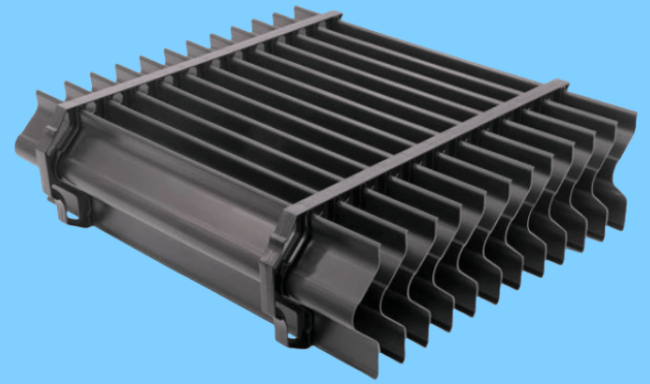

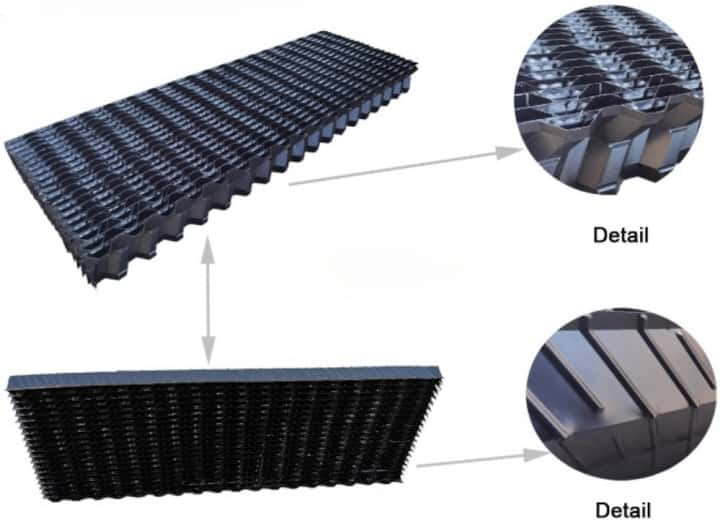

Drift eliminators are constructed from an alternating series of corrugated and wave PVC sheets, which are assembled to form closed cells. This closed cell structure maximizes the surface area available for droplet capture within a given volume, thereby enhancing their effectiveness. For example, cellular drift eliminators are specifically engineered to optimize drift removal efficiency while minimizing pressure drop. These devices come in various designs, including chevron, cellular, and blade types, each tailored to meet specific applications and improve overall performance. Selecting the appropriate type of drift eliminator is essential for maximizing efficiency and ensuring compliance with environmental regulations. The choice of drift eliminator depends on factors such as the cooling tower's design, operating conditions, and the desired balance between droplet capture efficiency and pressure drop.

2.The Mechanism of Drift Eliminators

Drift eliminators operate by creating barriers and directional changes in the airflow within a cooling tower. As air passes through these structures, water droplets are compelled to collide with surfaces, where they coalesce and are redirected back into the cooling system. This mechanism effectively minimizes the loss of water and chemicals due to drift. The primary role of drift eliminators is to capture and separate water droplets from the air stream before it is expelled from the cooling tower. This is accomplished through a combination of physical barriers and airflow redirection, which forces the air to release the entrained water droplets. The separated water is then channeled back into the cooling tower for recirculation, enhancing overall system efficiency.

(made by SPX Technologies)

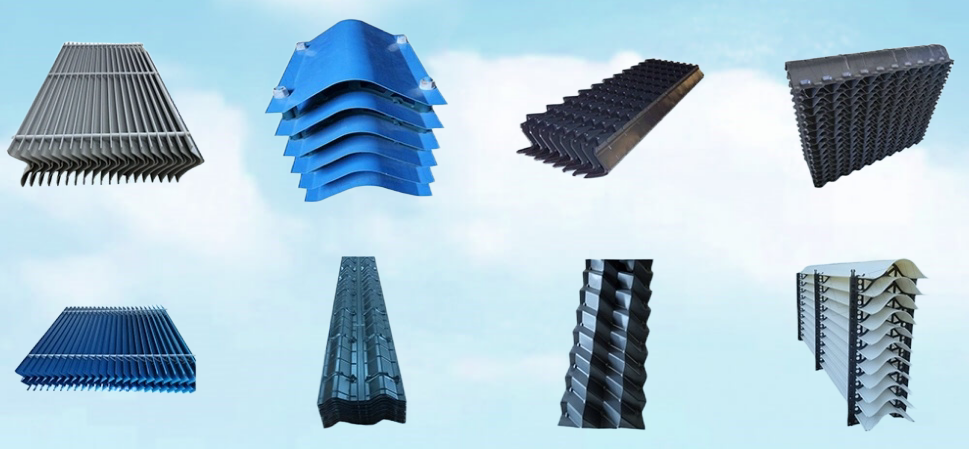

3. Types of drift eliminator

3.1 Chevron Drift Eliminators

Design Features:Chevron drift eliminators are characterized by closely spaced, angled blades arranged in a zigzag pattern. This innovative design significantly enhances droplet capture efficiency while minimizing pressure drop.

Applications:These eliminators are widely utilized in various cooling tower applications due to their effectiveness and low maintenance requirements.

3.2 Cellular Drift Eliminators

Design Features:

Cellular drift eliminators consist of interconnected cells or grids that form a labyrinthine pathway for the airflow. This structure maximizes the surface area available for droplet capture while maintaining minimal pressure loss.

Applications:Cellular drift eliminators are particularly effective in systems where low pressure drop is essential, making them well-suited for a range of industrial cooling applications.

3.3 Blade Drift Eliminators

Design Features:

Blade drift eliminators utilize closely spaced blades to create turbulence within the airflow, enhancing the capture of water droplets. These blades can be configured in either horizontal or vertical arrangements.

Applications: Known for their efficiency, blade drift eliminators are commonly employed in cooling towers that encounter high drift rate challenges.

4. Selection Criteria for Drift Eliminators

Choosing the appropriate type of drift eliminator is essential for optimizing efficiency and adhering to environmental regulations.When choosing a drift eliminator, several factors must be considered:

Factors to Consider

Cooling Tower Design: The overall design and configuration of the cooling tower will influence the type of drift eliminator best suited for the application.

Operating Conditions

Temperature, humidity, and the specific processes being cooled can affect performance requirements.

Balancing Efficiency and Pressure Drop

It’s essential to balance droplet capture efficiency with the pressure drop across the drift eliminator. A high-efficiency design may lead to increased pressure loss, which can negatively impact the cooling tower’s overall performance.

5. Drift Eliminators' Installation

The installation of drift eliminators is a crucial step in ensuring the efficient operation of cooling towers. Proper installation not only enhances the performance of the cooling system but also helps in reducing water loss and environmental impact.

Installation Process:

5.1 Preparation: Before installation, ensure that the cooling tower is cleaned and free from debris. Inspect the area where the drift eliminators will be placed to ensure proper fit and alignment.

5.2 Alignment: Carefully align the drift eliminators with the existing structure of the cooling tower. This may involve adjusting brackets or supports to ensure a snug fit.

5.3 Securing: Once aligned, secure the drift eliminators in place using appropriate fasteners. Ensure that they are tightly fixed to prevent any air leakage.

5.4 Sealing: Use sealing materials as necessary to prevent any gaps that could allow water droplets to escape. This step is vital for maximizing efficiency.

5.5 Testing: After installation, conduct a thorough inspection and testing to ensure that the drift eliminators are functioning as intended. Monitor for any signs of leakage or improper airflow.

By following these installation guidelines, you can ensure that your drift eliminators operate effectively, contributing to the overall efficiency and sustainability of your cooling tower system.

6. Cooling Tower PVC Drift Eliminators' Maintenance and Inspection

Importance of Regular Checks

Regular maintenance and inspection of drift eliminators are essential for ensuring their ongoing effectiveness. Over time, dirt, debris, and scale can accumulate, which can significantly reduce their efficiency.

Common Issues and Solutions

Common problems include blockages caused by dirt or scale, which can obstruct airflow and diminish droplet capture capabilities. Routine cleaning and maintenance are necessary to address these issues and maintain optimal performance. Regular inspections help identify potential problems early, allowing for timely intervention.

Best Practices for Upkeep

Establishing a regular inspection schedule and maintaining a log of all maintenance activities can greatly aid in promptly identifying and resolving issues. This proactive approach ensures that drift eliminators function efficiently and continue to meet operational and environmental standards.

7. Impact of Drift Eliminators on Cooling Tower Efficiency

The role of drift eliminators in optimizing cooling tower efficiency cannot be underestimated. These devices not only reduce the loss of water and chemicals but also improve energy efficiency. Well-maintained drift eliminators help cooling towers operate more effectively, reducing the load on other system components, such as water treatment units and pumps. By capturing and recirculating water droplets, drift eliminators help maintain consistent water levels and temperatures within the cooling system, ensuring smooth heat exchange processes.

In addition to enhancing operational efficiency, drift eliminators also help facilities meet air quality standards. By preventing harmful chemicals or pollutants from being released into the atmosphere, these devices ensure that industrial operations comply with environmental guidelines. This is crucial for companies looking to avoid regulatory fines, protect their reputation, and demonstrate their commitment to sustainable practices.

8. The Role of Drift Eliminators in Global Environmental Protection Efforts

As global awareness of environmental sustainability continues to grow, industries are under increasing pressure to reduce their environmental impact. The application of drift eliminators is an effective way for companies to contribute to global efforts in water conservation, reducing chemical emissions, and minimizing air pollution. In regions with strict environmental regulations, cooling towers with drift eliminators provide a simple yet effective solution to help businesses meet compliance requirements.

Governments and environmental agencies are also recognizing the value of these devices in promoting sustainable industrial practices. As a result, regulatory frameworks are likely to continue evolving, requiring cooling systems to adopt more efficient drift elimination technologies. This trend is expected to further drive innovation in the design and material composition of drift eliminators.

9. Regulatory Considerations

Environmental Regulations:Many regions have strict regulations governing the release of water and chemicals from industrial processes. Compliance with these regulations is essential to avoid fines and legal repercussions

Compliance Requirements:Drift eliminators play a key role in ensuring that cooling towers meet environmental standards. Selecting the appropriate drift eliminator and maintaining it properly can help facilities comply with regulations.

10. Choosing the Right Drift Eliminator Manufacturer

When selecting a manufacturer for drift eliminators, consider the following key factors:

Product Quality: Ensure the manufacturer provides high-quality drift eliminators that meet industry standards. Check for certifications and testing reports.

Technical Support: Choose a manufacturer that offers technical support and consulting services to receive professional guidance during the selection and maintenance processes.

Customer Reviews: Review feedback and testimonials from other customers to understand the manufacturer’s reputation and the quality of their after-sales service.

Delivery Capability: Confirm that the manufacturer can deliver on time to meet your project deadlines.

Customization Ability: Consider whether the manufacturer can provide tailored solutions based on specific requirements to accommodate different cooling tower designs and operating conditions.

Price Reasonableness: Compare prices from different manufacturers while ensuring quality, and select a supplier that offers good value for money.

Industry Experience: Prioritize manufacturers with extensive experience and a solid reputation in the industry.

11. Conclusion

In summary, understanding the role of drift eliminators in cooling towers is crucial for optimizing efficiency and minimizing environmental impact. Their proper selection and maintenance are essential not only for operational performance but also for compliance with environmental regulations. As technology advances, drift eliminators will continue to play a vital role in sustainable industrial practices, ensuring that cooling systems operate effectively while protecting our environment.

Our company meets all the key criteria: high-quality products, expert technical support, positive customer reviews, timely delivery, and customized solutions. We're here to help you optimize your cooling systems. Contact us today for a consultation!