In various industrial processes, gas-liquid separation plays a crucial role in ensuring the efficient operation and stability of the system. Particularly in industries such as chemical engineering, petrochemical, and natural gas processing, liquid droplets or mists in gas streams can significantly affect production efficiency, product quality, and even cause damage to equipment. To address this challenge, Demister Pads have emerged as a vital component in the gas-liquid separation process. These pads are designed to effectively remove micron-sized liquid droplets from vapor streams, ensuring better system performance.

What is a Demister Pad?

In various industrial processes, gas-liquid separation plays a crucial role in ensuring the efficient operation and stability of the system. Particularly in industries such as chemical engineering, petrochemical, and natural gas processing, liquid droplets or mists in gas streams can significantly affect production efficiency, product quality, and even cause damage to equipment. To address this challenge, Demister Pads have emerged as a vital component in the gas-liquid separation process. These pads are designed to effectively remove micron-sized liquid droplets from vapor streams, ensuring better system performance.

History of Demister Pads

The development of the Demister Pad began in the late 1950s with the introduction of a unique wrinkle-woven mesh apparatus. This innovative design effectively removed tiny liquid foam inclusions from vapor streams, exhibiting both high efficiency and low resistance. The Demister Pad’s performance in separating liquid droplets from gas streams was unparalleled by other gas-liquid separation technologies available at the time, leading to its widespread acceptance and use in many industrial applications.

Today, Demister Pads are typically placed at the top of packed towers, serving as essential components in various chemical, petrochemical, pharmaceutical, and other industries. These pads not only ensure mass transfer efficiency but also reduce the board spacing in the separation systems. They are integral in vertical cylindrical equipment and are often employed in processes such as desulfurization, oil mist removal, and toxic gas filtration.

Working Principles of Demister Pads

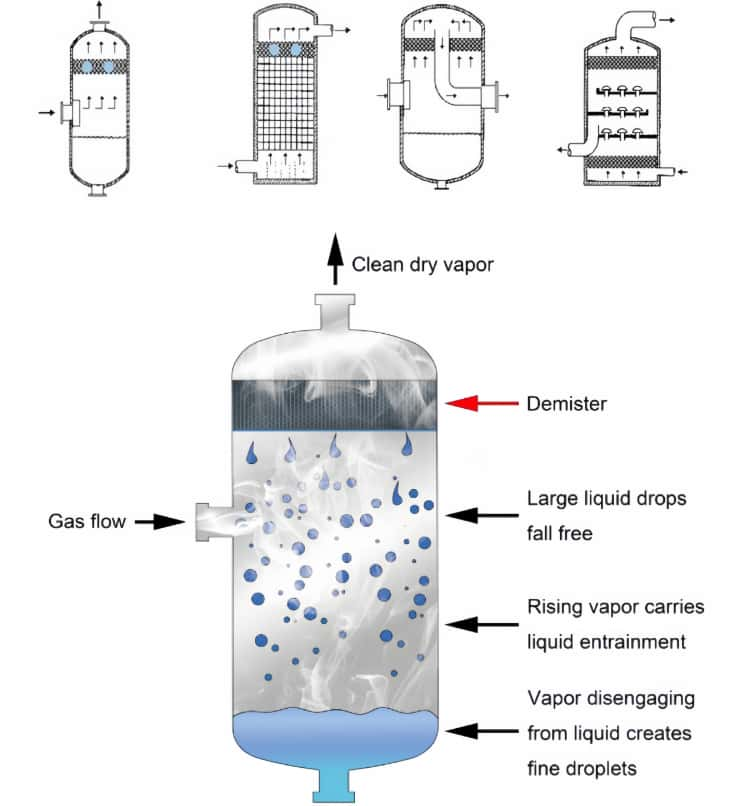

Demister Pads operate based on several key mechanisms that work together to remove liquid droplets or mist from the vapor stream. These mechanisms include:

- Inertial Impaction: As gas streams carrying liquid droplets rise through the Demister Pad, the droplets with higher inertia collide with the mesh filaments. The droplets coalesce on the mesh surfaces and are subsequently drained away.

- Diffusion: Smaller droplets within the gas stream exhibit a zigzag motion due to diffusion. This motion increases the chances of droplets coming into contact with the wire surfaces, allowing them to accumulate and form larger droplets.

- Direct Interception: Droplets that directly collide with the wire mesh are effectively captured and separated from the gas stream.

As gas passes through the mesh structure, the droplets grow larger, eventually falling freely under the force of gravity once the droplet's weight exceeds the upward force of the vapor and surface tension. The clean vapor then exits the Demister Pad and is discharged from the packed tower.

Materials Used in Demister Pads

The materials chosen for Demister Pads depend on the specific requirements of the process, such as temperature, pressure, and chemical resistance. Some of the common materials include:

- Metal Wires:

- Stainless Steel: Stainless Steel Demister Pad Known for its strength and excellent corrosion resistance, making it suitable for high-temperature and high-pressure environments.

- Aluminum: Lightweight and corrosion-resistant, commonly used in less demanding applications.

- Copper Steel: Offers great corrosion resistance in acidic environments.

- Monel: A nickel-copper alloy with exceptional corrosion resistance and high-temperature stability.

- Glass Fibers: These materials are heat-resistant and offer good chemical stability, making them ideal for many chemical processes.

- Plastic Plastic Demister Pad:

- Polypropylene (PP): pp demister pad has Lightweight, corrosion-resistant, and cost-effective, suitable for less aggressive environments.

- Polyvinyl Chloride (PVC): A durable, chemically resistant material often used where moderate corrosion resistance is needed.

- Polytetrafluoroethylene (PTFE): Known for its exceptional chemical resistance and high-temperature stability, ideal for highly corrosive and extreme conditions.

- Polyvinylidene Fluoride (PVDF): Offers superior chemical resistance, making it ideal for highly corrosive applications.

Types of Demister Pads

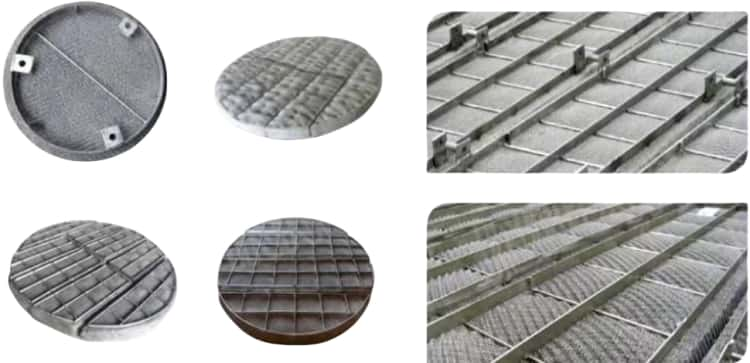

Demister Pads are available in a variety of materials, shapes, and designs to meet specific industrial requirements. Below is a breakdown of the different types of Demister Pads based on material, shape, supporting grids, and structure:

1. Materials of Demister Pads:

1.1 Metallic Materials:

- Stainless Steel: Offers high strength and corrosion resistance for a variety of industrial applications.

- Galvanized Steel: An affordable material with a protective zinc coating that helps prevent rust.

- Copper Steel: Highly corrosion-resistant, ideal for acidic environments.

- Monel: A high-strength, corrosion-resistant alloy, perfect for demanding applications.

1.2 Non-metallic Materials:

- Polypropylene (PP): Lightweight and resistant to corrosion, commonly used in mild chemical environments.

- Polyvinyl Chloride (PVC): A highly durable and chemically resistant material, often used in less aggressive environments.

- Polytetrafluoroethylene (PTFE): Known for its exceptional resistance to corrosion and high temperatures, PTFE is widely used in extreme environments.

- Polyvinylidene Fluoride (PVDF): Offers excellent chemical resistance for highly corrosive conditions.

2. Shapes of Demister Pads:

- Round: The most common and versatile shape, suitable for most tower sizes.

- Rectangular: Used for systems requiring specific configurations.

- Ring: Typically used when flexibility or ease of installation is necessary.

- Special Shapes: Custom-designed shapes for particular requirements.

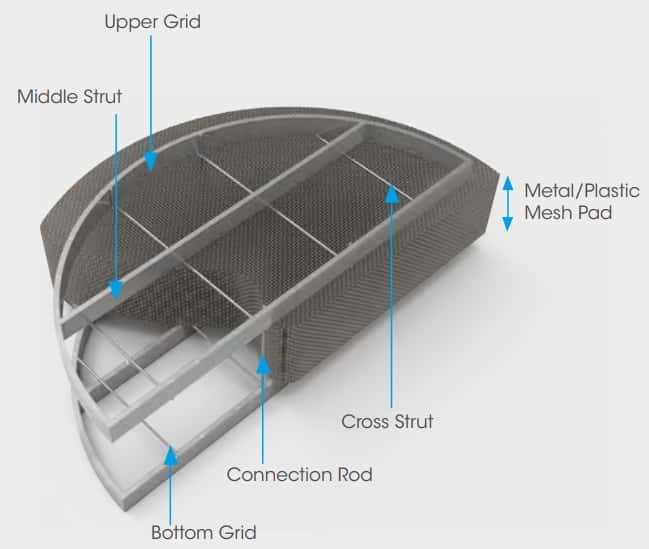

3. Supporting Grid Types:

- Round Bar Supporting Grid: Provides strong and reliable support, ideal for most standard applications.

- Flat Strip Supporting Grid: Offers increased rigidity and support, particularly for larger pads.

- Combination of Round Bar and Flat Strip: For enhanced strength.

- Crimped Wire Mesh and Supporting Grid: Flexible, crimped design to support the pad and improve performance.

4. Structure of Demister Pads:

- Integral Pads: Typically used for smaller diameter pads.

- Separated Part Pads: Used for larger diameter pads, facilitating easier handling, installation, and transportation.

Features of Demister Pads

- Simple Structure: Demister Pads are designed with simplicity in mind, often constructed from fibrous materials like metal wires or synthetic fibers. This design ensures easy manufacturing and cost-effectiveness.

- Lightweight and Easy to Transport: The lightweight nature of Demister Pads makes them easy to transport and install, reducing overall installation costs and time.

- High Porosity, Low Pressure Drop: These pads are highly porous, allowing for low resistance to gas flow. This minimizes energy consumption while ensuring efficient separation.

- Large Surface Area and High Separation Efficiency: Demister Pads provide a large surface area that enhances their ability to capture and coalesce liquid droplets, making them ideal for fine droplet removal.

- Easy Installation and Maintenance: With their simple design, Demister Pads are easy to install and require minimal maintenance. They are also easy to replace, reducing downtime.

- Durability and Longevity: Demister Pads are built to withstand harsh environmental conditions, including high temperatures and pressures, ensuring a long service life.

- Corrosion and Rust Resistance: Constructed from materials like stainless steel and fiberglass, Demister Pads are resistant to corrosion and rust, ensuring their continued performance in chemically aggressive environments.

Advantages of Demister Pads

- High Separation Efficiency: Demister Pads effectively retain liquid droplets, achieving high separation efficiency with low pressure drops.

- Low Resistance: Compared to other separation devices, Demister Pads offer lower gas resistance, reducing energy consumption and maintaining high separation efficiency.

- Versatility: These pads can accommodate a wide range of gas flow rates and droplet sizes, and they can be customized to meet specific process requirements.

- Ease of Maintenance: The simple design of Demister Pads makes them easy to clean and replace, reducing maintenance costs.Installation and Maintenance of Demister Pads

Applications of Demister Pads

Demister Pads play a critical role in a wide array of industries that require efficient gas-liquid separation. They are utilized to eliminate liquid droplets from gas streams, thereby ensuring the optimal functioning of various processes. Some of the key sectors where Demister Pads are commonly applied include:

- Petrochemical Industry: In petroleum refining processes, Demister Pads are essential for removing liquid droplets from gas streams. This prevents oil-gas mixing and ensures the stable operation of reactors and other equipment, thus optimizing the refining process.

- Natural Gas Processing: In natural gas transportation and processing, Demister Pads are used to remove water vapor and liquid hydrocarbons from the gas stream. This is crucial for preventing corrosion in pipelines, minimizing the risk of blockages, and ensuring the smooth flow of gas.

- Chemical Reaction Towers: During chemical reactions, gas streams often carry droplets that can interfere with the process. By installing Demister Pads in reaction towers, these droplets can be effectively separated, improving the efficiency and safety of chemical reactions.

- Air Purification: In industrial air treatment devices, Demister Pads help to remove moisture, oil mist, and other particulates. This ensures the air quality is maintained, preventing contamination of the surrounding environment and promoting safer working conditions.

Design and Installation of Demister Pads

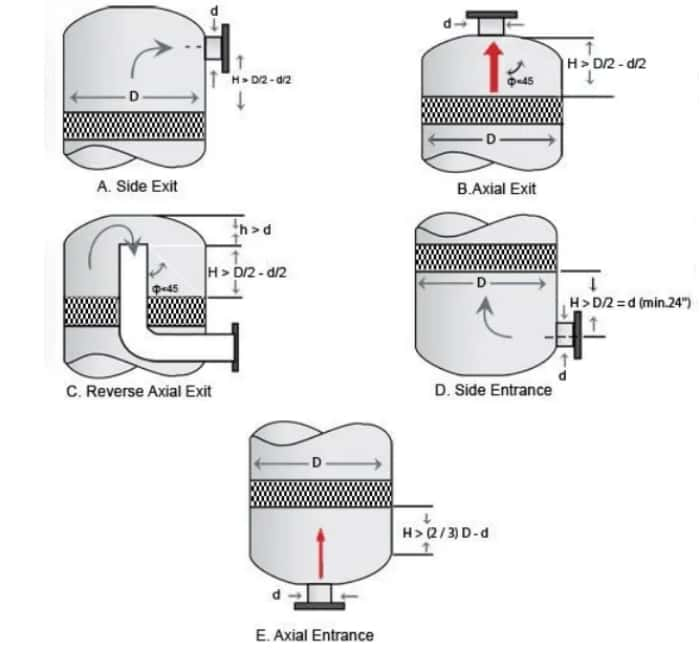

The design of a Demister Pad is a key factor in achieving high gas-liquid separation efficiency. Several important considerations must be taken into account to ensure that the Demister Pad performs optimally within the system. These factors include:

Key Design Factors:

- Gas Flow Velocity: The velocity at which gas flows through the Demister Pad is one of the most critical design parameters. If the gas flow velocity is too high, the liquid droplets may not have enough time to collide with the mesh fibers, preventing them from coalescing into larger droplets. Conversely, if the flow velocity is too low, insufficient turbulence may occur, reducing the effectiveness of droplet capture. The gas velocity should be carefully adjusted based on the specific requirements of the process and the separation system's capacity.

- Droplet Size: The size of the liquid droplets in the gas stream significantly impacts the design of the Demister Pad. Smaller droplets are more challenging to capture and may require a finer mesh or a higher-density fiber structure to increase the interception surface area. In contrast, larger droplets can be more easily separated but still require careful design to avoid re-entrainment into the gas flow.

- Operating Temperature and Pressure: The temperature and pressure conditions under which the Demister Pad will operate directly affect the choice of materials. For processes with high temperatures, materials like stainless steel or specialized alloys are typically used to ensure resistance to heat and pressure. In extreme pressure conditions, the design must be robust enough to maintain the structural integrity of the pad and ensure an effective gas-liquid interface.

- Separation Efficiency: The primary goal of a Demister Pad is to remove liquid droplets from the gas stream with high efficiency. Achieving this requires designing the pad with sufficient surface area for droplet capture. The gas should pass through the pad at an optimal speed and trajectory, ensuring maximum interaction between the droplets and the mesh fibers. Additionally, the design should prevent excessive liquid carryover, which can lead to fouling of downstream equipment.

- Structural Considerations: Demister Pads are often installed in gas-liquid separation towers, scrubbers, or similar containment vessels. Therefore, the pad must be designed to fit seamlessly within the structural framework of the system. It should be easy to install and remove for maintenance purposes and capable of withstanding mechanical stresses caused by gas flow or external conditions. The pad’s design should also facilitate installation in confined spaces and large systems.

- Pressure Drop: A critical consideration in the design of Demister Pads is minimizing the pressure drop across the pad. A high pressure drop can lead to energy inefficiency, excessive wear on equipment, and diminished performance of the separation system. The material, thickness, and mesh density of the pad should be optimized to balance high separation efficiency with minimal resistance to the gas flow.

Installation Considerations

Proper installation of Demister Pads is essential for achieving effective gas-liquid separation and maintaining long-term operational efficiency. Several factors must be carefully considered during installation:

- Proper Positioning: The Demister Pad should be positioned within the separation tower or vessel at the optimal height to ensure that the gas stream enters the pad at the correct angle and velocity. This maximizes droplet capture and minimizes the chances of liquid re-entrainment. In many systems, a distribution grid or support structure is employed to ensure even gas flow across the pad for consistent performance.

- Support and Fixing: Due to their size, Demister Pads require secure support to prevent sagging or displacement caused by gas flow or vibrations. The installation should include support frames or clips to maintain the pad's structural integrity and prevent any distortion that could reduce its performance.

- Access for Maintenance: Demister Pads must be easily accessible for routine maintenance and cleaning. Over time, debris or contaminants can accumulate on the pad, reducing its efficiency. Therefore, the installation should allow for quick removal, cleaning, or replacement of the pad, which is crucial for maintaining optimal operational performance.

- Avoiding Excessive Pressure Drop: The installation should ensure that the Demister Pad does not create an excessive pressure drop, which could impact the overall system's energy efficiency. The pad must be integrated seamlessly with the design of the gas-liquid separation system, aligning properly within the flow path to optimize performance and minimize energy loss.

- Leak Prevention: Proper sealing of the Demister Pad within the tower or vessel is essential to prevent gas leakage around the edges of the pad. This is particularly important in systems where maintaining a consistent gas composition is critical for the overall process.

Maintenance of Demister Pads

Demister Pads are crucial components in industrial systems designed to remove liquid droplets from gas streams. Like all industrial equipment, they require regular maintenance to ensure continued performance and efficiency over time. Due to the nature of their operation, Demister Pads are subject to wear and tear, as well as the accumulation of particles and liquid droplets from the gas stream. Over time, this buildup can lead to a decrease in efficiency, or even complete blockage, making it essential to perform regular maintenance.

Maintenance Methods:

To maintain the efficiency and longevity of Demister Pads, a consistent maintenance schedule should be followed. Regular cleaning is one of the most effective ways to prevent performance degradation. Specifically, it is important to address any issues related to clogging or contamination from solid particles, liquid accumulation, or chemical residue that might collect on the pad. A significant increase in pressure drop across the Demister Pad is often an early indicator that the pad may not be functioning optimally and may require attention.

One key factor to monitor is the buildup of dilute acids or other corrosive substances on the pad, which can erode or damage its structure. In such cases, it’s essential to clean the pad thoroughly and remove any harmful residues. Natural drying, particularly under direct sunlight, is recommended to avoid moisture retention and mold growth, which can further deteriorate the pad. Avoid using aggressive chemical cleaners that may damage the material of the pad.

Routine visual inspections should be performed to check for any visible signs of wear, such as corrosion, physical damage, or excessive degradation of the pad material. If any cracks, tears, or holes are found, the pad should be replaced immediately to maintain system integrity. Additionally, it's crucial to inspect the supporting structure, as misalignment or improper installation can affect the performance of the Demister Pad.

In highly demanding environments, where the gas stream contains significant levels of particulate matter or corrosive substances, more frequent cleaning or replacement cycles may be necessary. It’s also essential to ensure that the Demister Pad is properly installed and secured to avoid any vibrations or misalignment that could compromise its effectiveness. Proper documentation of the maintenance activities, including cleaning, inspections, and repairs, will help track the pad’s performance and predict the optimal time for replacement.

Additional Considerations:

Consider implementing automated monitoring systems that can track the pressure drop, temperature, and overall performance of the Demister Pads. This real-time data can provide early warning signs of efficiency loss and allow for more proactive maintenance planning. With a comprehensive maintenance strategy, Demister Pads can operate at peak performance, significantly extending their service life and minimizing downtime in industrial processes.

Conclusion

Demister Pads are a highly efficient and cost-effective solution for gas-liquid separation in various industrial applications. By employing simple physical principles, they effectively remove liquid droplets from gas streams, enhancing system efficiency and protecting equipment from damage. As industrial technology continues to evolve, the materials and designs of Demister Pads are becoming increasingly advanced. It is expected that these innovations will provide even more efficient and durable mist eliminators, offering superior gas-liquid separation solutions for a wide range of industrial processes.