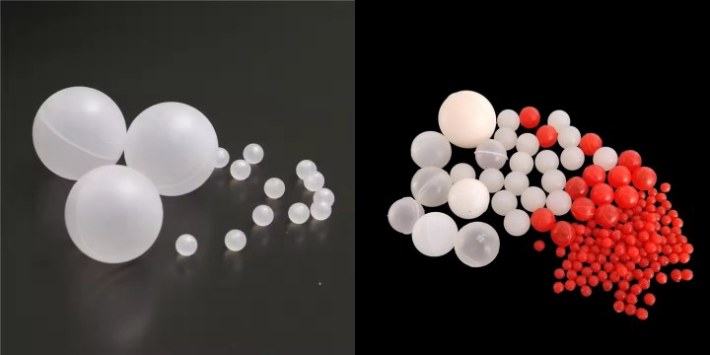

Hollow plastic balls are lightweight, durable, and versatile components used across various industries and environmental sectors. These spherical products are highly valued for their unique design, which enhances buoyancy, chemical resistance, and insulating properties. Hollow plastic balls play crucial roles in applications such as liquid surface coverage, wastewater treatment, fluid control, pollution management, and more. This article delves into the characteristics, manufacturing process, and wide array of industrial and environmental applications of hollow plastic balls.

Characteristics of Hollow Plastic Balls

The performance of hollow plastic balls is driven by their structural design and the materials used in their manufacture. Key characteristics include:

1. Lightweight

The hollow structure of these balls significantly reduces their weight, making them ideal for applications requiring buoyancy or lightweight components. Their low density allows them to float on the surface of liquids or gases with minimal resistance.

2. Durability

Made from high-quality plastics like polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), hollow plastic balls exhibit excellent resistance to impacts, wear, and environmental factors. These materials ensure long-lasting performance even in harsh or corrosive conditions.

3. Chemical Resistance

Hollow plastic balls are resistant to a wide range of chemicals, including acids, bases, and solvents, making them suitable for use in industries such as chemicals, petrochemicals, and pharmaceuticals, where exposure to aggressive chemicals is common.

4. Buoyancy

The air-filled cavity within the balls provides superior buoyancy, making them ideal for applications in liquid surface coverage, oil spill recovery, and water treatment.

5. Thermal and Acoustic Insulation

Hollow plastic balls offer low thermal conductivity, which helps to reduce heat transfer in high-temperature applications. Their structure also helps in noise dampening, making them useful for sound insulation in industrial environments.

6. Versatility

With their customizable sizes , shapes, and materials, hollow plastic balls are adaptable to a wide variety of industrial, environmental, and consumer applications.

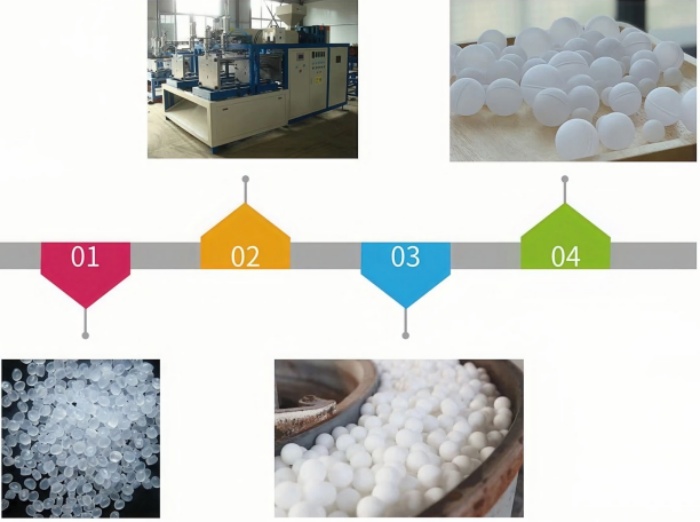

Manufacturing Process of Hollow Plastic Balls

The production of hollow plastic balls requires precision and careful control to ensure consistent quality. The common steps in their manufacturing process include:

1. Material Selection

The choice of material is based on the required physical and chemical properties for specific applications. Common materials include:

- Polyethylene (PE): Lightweight and resistant to most chemicals.

- Polypropylene (PP): Offers higher strength and better temperature tolerance.

- Polyvinyl Chloride (PVC): Known for excellent chemical resistance, particularly in acidic environments.

- Specialty Plastics (e.g., PTFE, PVDF): Used in highly specialized applications requiring extreme temperature resistance and chemical stability.

2. Molding Processes

The key molding techniques for creating hollow plastic balls are:

- Injection Molding: Heated plastic is injected into a precision mold to create small hollow spheres.

- Blow Molding: A preform is inflated inside a mold to create a hollow sphere, ideal for larger balls.

3. Cooling and Finishing

After the molding process, the balls are cooled to solidify their shape. Excess material is trimmed, and the surface is polished to ensure smoothness and dimensional accuracy.

4. Quality Control

To ensure that the hollow plastic balls meet the required standards, rigorous testing is conducted. This includes checks for size accuracy, impact resistance, chemical stability, buoyancy, and overall durability.

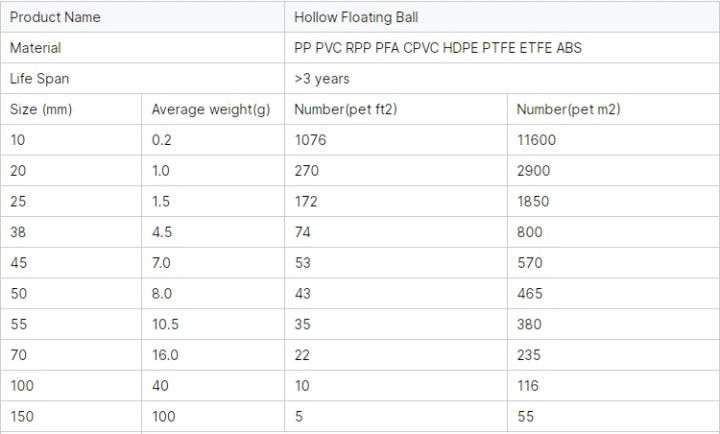

Size and Characters of Hollow Plastic Balls

The size of hollow plastic balls could be 6mm 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 38mm, 50mm, 55mm, 70mm, 80mm, 100mm, 150mm.

Industrial Applications of Hollow Plastic Balls

1. Liquid Surface Coverage in Storage Tanks

Hollow plastic balls are commonly used to cover the surface of liquids in storage tanks in industries such as chemicals, pharmaceuticals, and petroleum. The benefits include:

- Evaporation Reduction: Minimizes the evaporation of volatile substances.

- Contamination Prevention: Helps keep out dust, debris, and airborne contaminants.

- Emission Reduction: Limits the release of volatile organic compounds (VOCs).

2. Thermal and Acoustic Insulation

- Thermal Insulation: Reduces energy loss in high-temperature systems.

- Noise Reduction: Mitigates noise pollution in industrial environments.

3. Fluid Control

- Liquid Level Control: Used in automated liquid level regulation systems.

- Pressure Stabilization: Helps balance pressure fluctuations in fluid systems.

Environmental Applications of Hollow Plastic Balls

1. Wastewater Treatment

- Increased Surface Area: Provides surface area for microorganisms to grow and degrade organic pollutants.

- Improved Efficiency: Optimizes microbial activity, enhancing wastewater purification rates.

- Chemical Stability: Can withstand harsh acidic or alkaline environments.

2. Pollution Control

- Air Pollution: Used in gas scrubbers to reduce harmful emissions in chemical plants.

- Acid Mist and Dust Removal: Absorbs and neutralizes acidic mist and dust particles in exhaust gases.

3. Oil Spill Management

The buoyant nature of hollow plastic balls makes them highly effective in oil spill response. They help contain and recover spilled oil, minimizing environmental damage.

Special Applications: Shade Balls for Water Conservation

One notable application of hollow plastic balls is the use of shade balls, typically 100mm in diameter, in water conservation efforts.

1. Water Conservation

Shade balls help reduce water evaporation in reservoirs, especially in arid climates or during drought conditions. They can save millions of gallons of water annually.

2. Algae Growth Prevention

Shade balls block sunlight from reaching the water, preventing algae formation and maintaining water quality.

3. Temperature Regulation

Shade balls help stabilize the temperature of stored water, which is important for water treatment processes.

4. Contamination Prevention

Shade balls act as physical barriers against debris and wildlife, ensuring that the water remains clean and free from contaminants.

Notable Use Case

In Los Angeles, millions of shade balls were deployed in the city's reservoirs to conserve water during drought conditions. This innovative strategy highlighted their effectiveness in large-scale water management.

Conclusion

Hollow plastic balls are essential components with diverse applications in both industrial and environmental sectors. Their lightweight, durable, and chemically stable properties, combined with their ability to provide buoyancy, insulation, and surface coverage, make them indispensable. From wastewater treatment and pollution control to fluid management and oil spill recovery, hollow plastic balls continue to offer innovative solutions for improving industrial efficiency and safeguarding the environment.