Wastewater treatment is one of the key processes necessary to protect the environment. As industries grow and urban populations rise, managing and treating large volumes of wastewater has become increasingly challenging. To meet these demands, wastewater treatment plants are employing advanced technologies to improve the efficiency and effectiveness of their processes. Among these innovative solutions is the Moving Bed Biofilm Reactor (MBBR) technology, a cutting-edge method that has transformed biological wastewater treatment.

Central to the success of MBBR ( moving bed biofilm reactor )systems is the use of specialized carriers known as mbbr media. These carriers provide a surface for biofilm to grow, which enhances the biological treatment of wastewater. MBBR moving bed bioreactor media media plays a pivotal role in the process, making it possible for wastewater treatment plants to achieve higher levels of efficiency while maintaining cost-effectiveness. This article provides an in-depth explanation of MBBR media, covering its types, features, advantages, applications, and challenges in modern wastewater treatment systems.

1. History and Development of MBBR Technology

The development of MBBR technology is rooted in the evolution of biofilm-based treatment systems. Biofilm reactors have long been used in wastewater treatment, with fixed-film systems such as trickling filters being early examples. However, as the limitations of traditional biofilm systems became apparent — such as clogging and low efficiency — engineers began to seek more innovative solutions.

The Moving Bed Biofilm Reactor technology was first developed in the late 1980s by the Norwegian company Kaldnes, which introduced the concept of using small plastic carriers to support biofilm growth. These carriers, or media, are suspended and continuously mixed within the reactor, providing an optimal environment for microbial activity. The continuous motion of the media allows for efficient oxygen transfer and promotes the detachment of excess biofilm, preventing overgrowth and ensuring stable operation.

Over the years, MBBR moving bed bioreactor technology has been adopted by wastewater treatment facilities worldwide due to its robustness, efficiency, and adaptability to different wastewater characteristics.

2. What is MBBR Wastewater Treatment

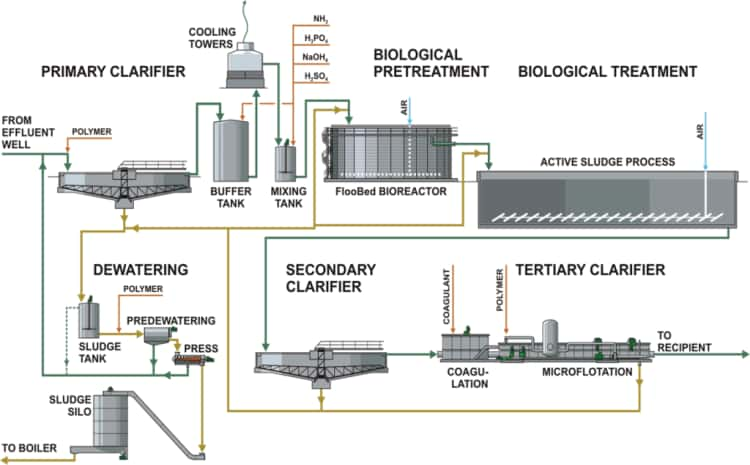

Before explaining MBBR (Moving Bed Biofilm Reactor), it’s important to understand that it falls under the category of biological wastewater treatment, as opposed to chemical or mechanical processes. Biological processes use microorganisms like bacteria or nematodes to break down organic matter in wastewater. These microorganisms naturally decompose waste, turning complex materials into simpler substances that can be filtered out in later treatment steps.

Biological wastewater treatment is often a secondary stage after primary treatment and is sometimes combined with other processes. Whether used alone or in a multi-step system, biological treatment is an effective, eco-friendly, and economical solution.

MBBR is a specific type of biological treatment developed by Norwegian researchers in the late 1980s. It combines the advantages of activated sludge processes and biofilm technology, addressing some of the shortcomings of other biological treatments. MBBR uses plastic carriers with biofilm to break down waste and is particularly effective for nitrification and denitrification.

MBBR is often part of a larger wastewater treatment system, including processes like grit removal and disinfection. It can be customized based on the specific purification needs of different facilities, making it a versatile and efficient treatment method.

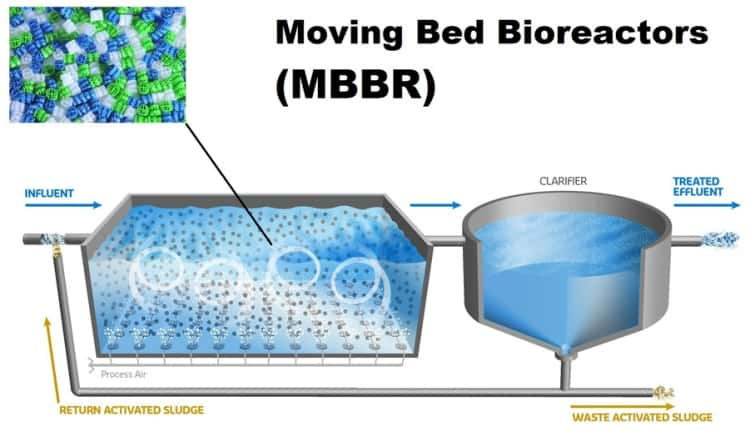

3. How MBBR Wastewater Treatment Works

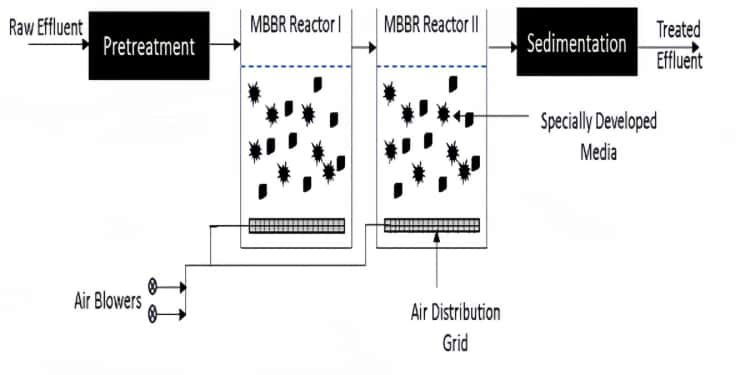

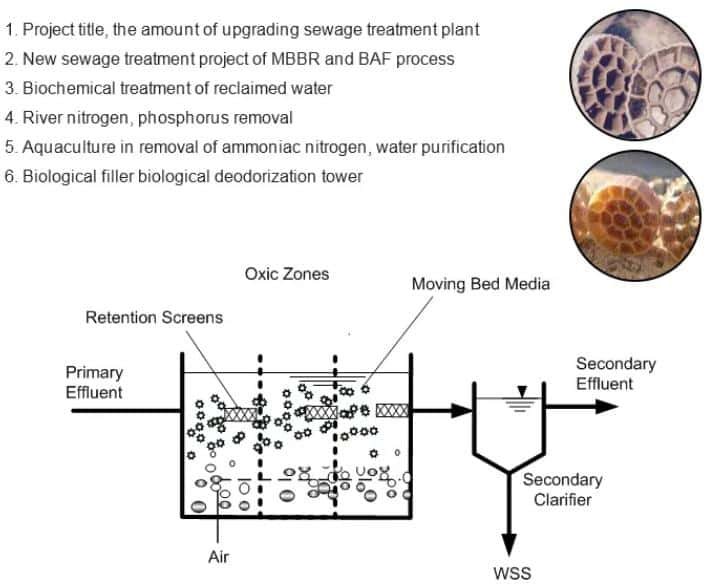

The MBBR (Moving Bed Biofilm Reactor) process is an efficient biological method for treating wastewater. It involves key components that work together to break down pollutants and improve water quality.

Basin: Wastewater flows into a basin, or aeration tank, where the treatment begins. The size of the tank varies based on the plant's requirements. The basin is open at the top to allow air, facilitating an aerobic filtration process crucial for the microorganisms that break down the waste.

Media: The basin contains thousands of plastic carriers, or media, that take up 50-70% of the tank’s volume. These carriers provide a large surface area for biofilm to grow, where microorganisms attach and degrade pollutants. The media are neutrally buoyant, meaning they mix throughout the water without sinking or floating, ensuring uniform treatment.

Aeration Grid: An aeration grid at the bottom of the tank circulates air and keeps the media in motion, allowing the biofilm to contact waste particles efficiently. This movement enhances the breakdown of organic matter, with oxygen introduced to support aerobic decomposition.

Sieve: A sieve at the tank’s outlet prevents the media from leaving the tank while allowing treated water to pass through, ensuring that the carriers stay inside for continuous use.

Biological Process: Microorganisms on the media consume organic waste, converting it into harmless by-products like carbon dioxide and water. For specific treatments like denitrification, bacteria such as Pseudomonas are introduced to remove nitrates. The MBBR system can also handle nitrification, making it versatile for different wastewater needs.

Efficiency and Adaptability: The MBBR system is highly efficient and flexible, capable of handling variable loads and adapting to different treatment requirements. Its design ensures continuous and effective treatment, even under changing conditions, making it more reliable and efficient compared to traditional systems.

4. What is MBBR Media and How It Works

MBBR (Moving Bed Biofilm Reactor) media are small plastic carriers designed to support the growth of beneficial microorganisms used in wastewater treatment. These moving bed bioreactor media play a critical role in the MBBR process, which is a biological method for treating sewage and industrial wastewater. The media act as a home for biofilm (microorganisms) that break down pollutants in the water, making the treatment process more efficient and effective. Here's a closer look at what MBBR media are, how they work, and why they are essential in wastewater treatment.

Design and Structure of MBBR Media

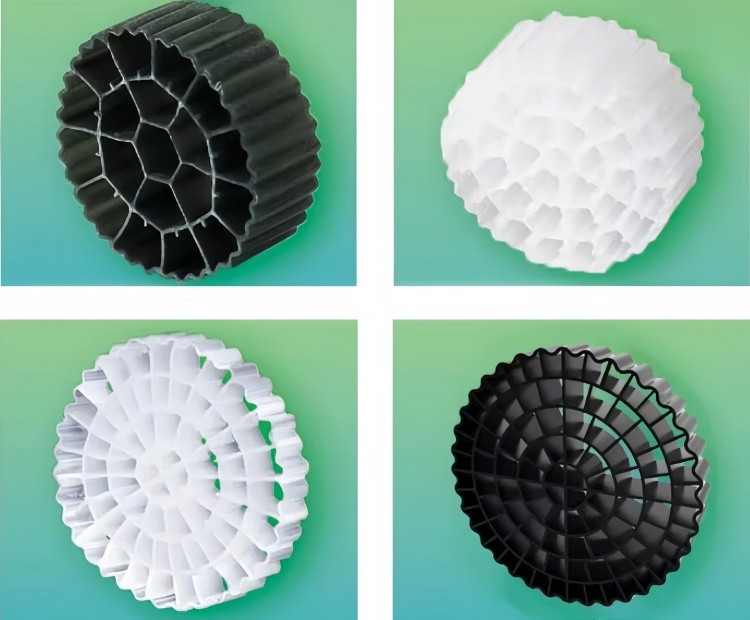

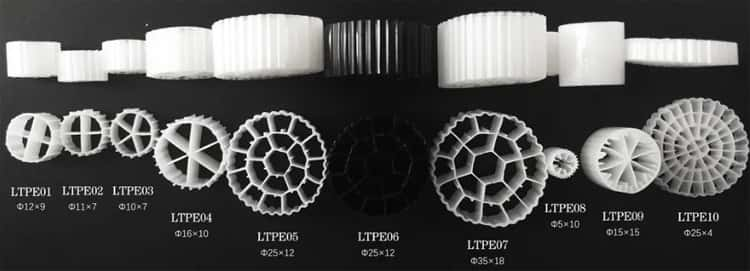

MBBR media are typically small, durable pieces of plastic that come in various shapes such as wheel-like structures, thin discs, or squares. Their design is optimized to provide the maximum surface area for biofilm growth. By maximizing surface area, the media create an ideal environment for beneficial microorganisms to attach and multiply. Some MBBR media resemble wheel-shaped pasta, where the spokes create more surface area for bacterial growth. Others are thin discs or squares designed to remain suspended in the water and mix efficiently with the wastewater.

The media are usually made from materials like polyethylene or polypropylene, which are durable and resistant to degradation in wastewater environments. They are designed to be neutrally buoyant, meaning they do not sink or float, but remain suspended and move throughout the tank.

How MBBR Media Work in Wastewater Treatment

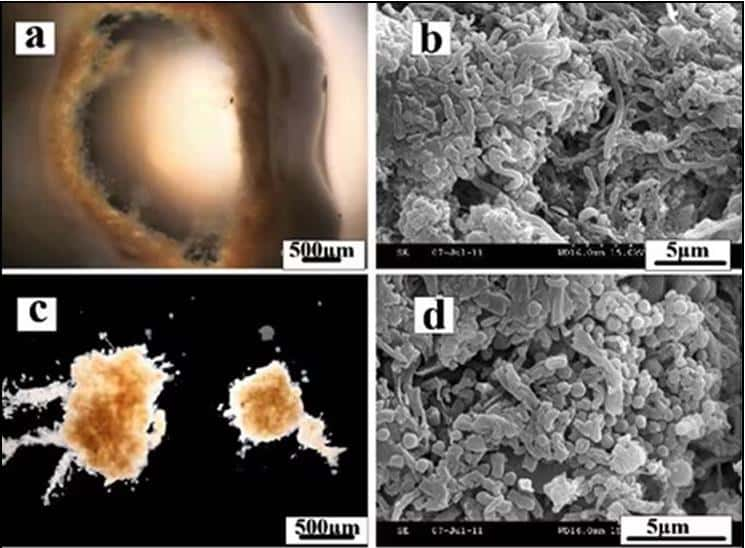

MBBR media carriers are used in aeration tanks in wastewater treatment plants. As the wastewater flows through the treatment tank, the media are constantly mixed by aeration or mechanical stirring. Oxygen is introduced into the tank through an aeration grid, which helps the biofilm grow and thrive. The biofilm, consisting of microorganisms such as bacteria, fungi, and protozoa, attaches to the surface of the media and consumes the organic pollutants in the wastewater.

The microorganisms on the media break down the organic matter into simpler substances, such as carbon dioxide and water, through biological processes. This process is highly efficient because the large surface area provided by the media allows for a greater number of bacteria to thrive, speeding up the decomposition of waste.

A mesh sieve is placed at the outlet of the tank to ensure that the media remain in the tank while the treated water exits. The biofilm remains active on the media, continuously treating the incoming wastewater.

5. Advantages of MBBR Media

One of the main advantages of using moving bed bioreactor media media in wastewater treatment is the efficiency it provides. The large surface area of the media supports a high concentration of microorganisms, which leads to faster and more effective waste decomposition. This makes MBBR systems more compact than traditional treatment systems, allowing for a smaller physical footprint while still handling large volumes of wastewater.

MBBR media are also easy to maintain. Since the microorganisms are attached to the media, they do not need to be periodically removed or replaced, unlike in conventional systems where sludge handling can be a challenge. The media also make it easier to manage fluctuations in wastewater load, as the biofilm adjusts to varying conditions and continues to treat the water effectively.

6. Applications of MBBR Media

MBBR media are used in a variety of wastewater treatment applications, including municipal sewage treatment plants (STPs) and industrial wastewater systems. Moving bed bioreactor medias are particularly useful in treating wastewater with high levels of organic contaminants or where biological nutrient removal is required. Additionally, MBBR systems are flexible and can be easily scaled or retrofitted into existing treatment plants to improve their efficiency.

7. Types and Features of MBBR Media

Types of MBBR Media

Here are some examples of different types of MBBR media:

Sponge-type carriers: These carriers have strong mechanical properties, a large specific surface area, and a textured surface that enhances biofilm attachment. Made from flexible, spongy materials, they are more prone to wear compared to other types due to their soft structure.

Chip-type carriers: Thin and filled with fine pores, chip-type carriers are both flexible and highly resistant to wear, making them durable and effective.(Mutag biochip)

Coin-shaped carriers: These thin, coin-like carriers allow wastewater to flow through both sides, reducing the risk of fouling. Some chip-type carriers also share this coin-like shape.

Tube-shaped carriers: Long, narrow, tube-shaped carriers offer an extended surface area for microbial growth. Their shape keeps them suspended in water without stacking together. However, their hollow design can sometimes make them susceptible to clogging.

MBBR Media Sizes

MBBR moving bed bioreactor media come in various sizes, and many manufacturers offer custom sizes tailored to specific wastewater treatment facility needs. Common sizes include 10 mm by 7.5 mm, 25 mm by 8 mm, and 25 mm by 10 mm. Whether large or small, wastewater treatment facilities can find the right size to fit their requirements.

K1 mbbr media:12*9mm

K3 mbbr media: 25*12mm

K5 mbbr bio media: 25*4mm

To ensure you're choosing the correct MBBR media, it's essential to know the size you need. Contact your MBBR media supplier or manufacturer to explore available options and select the best one for your application.

MBBR Media Colors

You can customize the color of MBBR media to suit your wastewater treatment facility. While white is the most common, other available colors include red, green, blue, and brown. Choose a color that matches your facility’s appearance while adhering to any required regulations or standards.

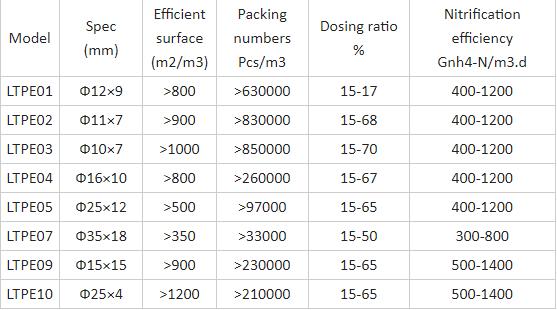

MBBR Media Specifications

8. Calculation of MBBR Media

Calculating the volume of MBBR (Moving Bed Biofilm Reactor) media required for a wastewater treatment facility is a critical step in designing an effective treatment system. The correct amount of media ensures optimal performance by providing adequate surface area for biofilm growth, which is responsible for breaking down organic pollutants in the wastewater. Here's a guide to how MBBR media volume is calculated and some key considerations to keep in mind.

Step 1: Determining the Organic Load

The first step in calculating the required volume of MBBR media is to assess the organic load of the wastewater. The organic load is the total amount of organic pollutants present in the wastewater that need to be treated. It can be calculated using the following formula:

Organic load = flow rate × (influent concentration – effluent concentration)

8.1.1 Flow rate: This is the volume of wastewater flowing through the system over time, typically measured in cubic meters per hour (m³/h) or liters per second (L/s).

8.1.2 Influent concentration: The concentration of organic matter (such as biochemical oxygen demand, or BOD) in the incoming wastewater.

8.1.3 Effluent concentration: The desired concentration of organic matter in the treated water, i.e., the target pollutant level after treatment.

By multiplying the flow rate by the difference in pollutant concentration between the influent and effluent, the organic load (measured in kg/day or similar units) is obtained. This represents the amount of organic material the biofilm on the MBBR media will need to break down.

Step 2: Determining the Media Volume

Once the organic load is known, the next step is to determine the volume of MBBR media required to handle this load. This depends on the removal efficiency of the media, which varies based on the type of media and the design of the treatment process.

Media volume = Organic load / Removal efficiency

8.2.1 Removal efficiency: This refers to the media’s capacity to remove organic pollutants, usually expressed as kilograms of BOD removed per cubic meter of media per day (kg BOD/m³/day). Each type of MBBR media has a different removal efficiency based on its surface area, material composition, and the environmental conditions in the tank.

8.2.2 Organic load: The amount of organic matter the system must process daily.

To calculate the required amount of MBBR media, divide the organic load by the removal efficiency of the selected media. This will give the necessary media volume, typically in cubic meters (m³).

Step 3: Adjusting for Media Fill Fraction

In practice, not all of the tank’s volume is filled with MBBR media. The media typically occupy only 50-70% of the total reactor volume to allow for adequate water flow and aeration. This is known as the media fill fraction or media filling rate.

The total media volume can be adjusted using the fill fraction:

Adjusted media volume = (Required media volume) / Fill fraction

For example, if the calculated media volume is 10 m³ and the media fill fraction is 60%, the adjusted media volume would be:

Adjusted media volume = 10 m³ / 0.60 = 16.67 m³

This accounts for the space required to allow water and air to flow through the reactor without clogging the media.

Step 4: Factoring in Hydraulic Retention Time (HRT)

Hydraulic Retention Time (HRT) is the time that wastewater spends in the reactor. It influences the effectiveness of the treatment process and should be considered when calculating media volume. A longer HRT allows the biofilm more time to break down organic pollutants, which can reduce the required media volume or improve treatment efficiency.

HRT can be adjusted by changing the flow rate or reactor size, impacting the overall media calculation. Ensuring that HRT is sufficient for your treatment goals is essential for optimal media performance.

Step 5: Other Considerations

Aeration requirements: Adequate aeration is critical to the performance of MBBR media, as it ensures that oxygen is available for the biofilm to carry out aerobic decomposition. The aeration rate should be balanced with the media volume to avoid inadequate oxygen supply.

Water temperature: Temperature affects the activity of microorganisms in the biofilm. Higher temperatures can increase microbial activity and efficiency, potentially reducing the media volume needed. In colder climates, more media may be necessary to achieve the same level of treatment.

System design: The layout of the reactor, such as the placement of aeration grids and media movement, can also affect the calculation. Proper design ensures that the media are evenly distributed and that biofilm growth is optimized.

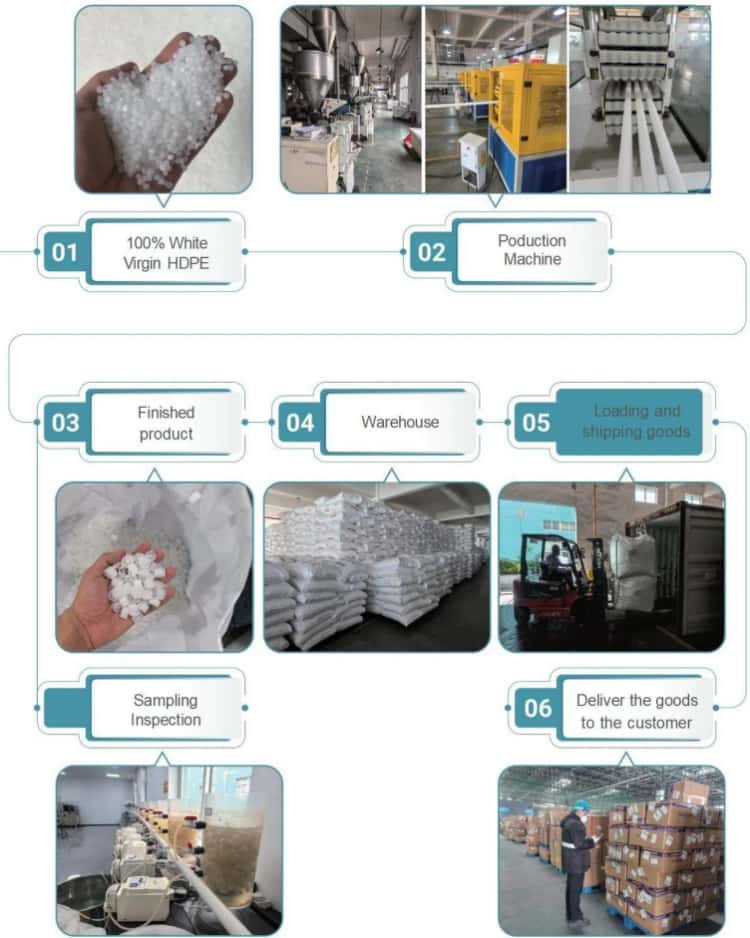

9. Why Choose Lianchuang MBBR Media?

When selecting MBBR (Moving Bed Biofilm Reactor) media for your wastewater treatment system, Lianchuang offers several advantages that make their products stand out:

1. High-Quality Control Process

2. Cost-Effective Production

Lianchuang moving bed bioreactor media are manufactured using advanced production techniques and high-quality materials. This ensures that while maintaining excellent product performance, the production costs are optimized, allowing you to get high-performance media at a more competitive price, thus lowering your overall investment costs.

3. Door-to-Door Delivery Service

To provide convenience, Lianchuang offers fast and secure door-to-door delivery services, ensuring that the products are delivered to your project site on time, saving both logistics costs and time, and improving operational efficiency.

4. Outstanding Product Performance

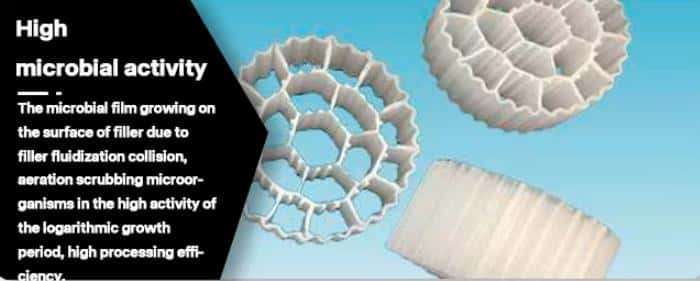

Lianchuang MBBR media offer the following key features:

Large Specific Surface Area: Provides more attachment points for biofilm, enhancing microbial treatment efficiency.

Good Hydrophilicity: Promotes the rapid formation and stability of biofilms.

High Biological Activity: Encourages the active growth of microorganisms, improving wastewater treatment efficiency.

Long Service Life: Made from durable materials, ensuring stable long-term operation.

5. Extensive Industry Experience

With many years of experience in the wastewater treatment field, Lianchuang is able to provide professional technical support and solutions tailored to the specific needs of customers, ensuring the successful implementation of projects.

6. Excellent After-Sales Service

Lianchuang places great emphasis on customer satisfaction, offering comprehensive after-sales services, including technical consultation and product maintenance, to ensure smooth and satisfactory use throughout the product’s lifecycle.

By choosing Lianchuang MBBR media, you gain high-quality products and professional services, providing a solid foundation for the successful advancement of your wastewater treatment project.