Pall rings and Raschig rings are both types of random packing used in chemical processing and industrial applications for processes such as distillation, absorption, and stripping. In chemical engineering. Their function is to increase the contact surface of gas and liquid and make them mix strongly with each other. Below, we will delve into the similarities and differences between the pall ring and raschig ring packing.

1 Historical Background

1.1 Development of Raschig Rings

Raschig rings were developed by German chemist Friedrich Raschig in the early 20th century. He was seeking an efficient way to maximize surface area in packed columns, essential for gas-liquid contact. His invention revolutionized the design of packing materials. These cylindrical rings, typically made of ceramic, metal, or plastic, have been widely used due to their simple design and relatively low cost. Raschig rings were among the earliest examples of random packing and laid the foundation for subsequent innovations in column packing technology.

1.2 Emergence of Pall Rings

In the 1940s, advancements in random packing technology led to the development of the Pall ring. Pall rings were designed to overcome the limitations of Raschig rings, particularly in terms of liquid flow distribution and pressure drop. With additional openings in their cylindrical structure, Pall rings improved gas and liquid contact efficiency while maintaining mechanical strength. This modification represented a significant leap in enhancing the performance of packed columns, especially for mass transfer processes.

2. Structural Comparison

2.1 Shape Comparison:

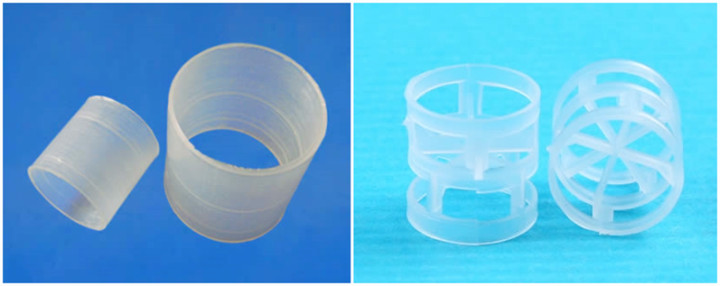

Raschig ring is the simplest structure of all types of random packing.diameter is larger than 100 mm Raschig ring is commonly filled neatly when using, but the smaller size which the diameter is smaller than 4 mm , typically made from ceramic or metal, and were among the earliest random packing designs They are characterized by their cylindrical shape without internal structural features.

Pall rings are a type of structured packing with a cylindrical shape and several internal and external structural features, such as small windows or holes and internal crossbars, designed to increase surface area and improve efficiency in mass transfer processes.

2.2 Material

They both can be made with material metal(321,304, 316L etc), plastic (pp,hdpe,pvdf,pvc,pe etc), or ceramic. As we often been asked the Here are the differences between Pall rings and Raschig rings, below information for your reference.

2.3 Physical Structure and Design Differences

The fundamental difference between Raschig rings and Pall rings lies in their structural design. Raschig rings are simple, hollow cylinders with a uniform shape. In contrast, Pall rings are also cylindrical but feature multiple perforations or slits in the walls. These perforations increase the number of edges available for gas-liquid contact and enhance the overall surface area for mass transfer. The additional openings in Pall rings also allow for more uniform distribution of liquids throughout the packed bed, reducing the likelihood of channeling, a common problem with Raschig rings.

2.4 Surface Area and Void Space Characteristics

Surface area and void space are critical factors in determining the efficiency of random packing materials. Pall rings generally offer more surface area than Raschig rings due to their complex design. This increased surface area translates into better gas-liquid interaction, improving the overall performance of the packed column. Additionally, the void fraction in Pall rings is higher than in Raschig rings, which allows for better fluid flow and less pressure drop.

3. Performance and Efficiency

3.1 Pressure Drop Considerations

One of the main factors that engineers must consider when selecting packing materials is the pressure drop across the packed bed. Raschig rings, due to their simpler design, tend to have a higher pressure drop compared to Pall rings. This is because the cylindrical structure of Raschig rings does not allow for as smooth a flow of gases and liquids, leading to more resistance. Pall rings, on the other hand, reduce pressure drop by facilitating better distribution of fluids through the bed, allowing for more efficient gas and liquid flow.

3.2 Mass Transfer Efficiency

Mass transfer efficiency is crucial in separation processes such as distillation and absorption. Pall rings outperform Raschig rings in this regard, thanks to their increased surface area and enhanced fluid distribution. The openings in Pall rings promote a more uniform contact between the gas and liquid phases, allowing for more effective mass transfer. Raschig rings, while still effective, tend to have lower mass transfer efficiency due to their limited surface area and potential for liquid channeling.

3.3 Heat Transfer Capabilities

While Raschig rings and Pall rings are primarily designed for mass transfer applications, heat transfer also plays a role in certain processes. Both packing types provide reasonable heat transfer capabilities, although Pall rings may offer slight improvements due to their more open structure, which promotes better mixing and flow of fluids.

3.4 Hydrodynamic Performance

The hydrodynamic performance of random packing refers to how well the packing material handles the flow of liquids and gases within the column. Pall rings exhibit superior hydrodynamic performance compared to Raschig rings, as their design allows for a more uniform distribution of liquids, reducing the risk of flooding and channeling. This improved distribution also minimizes the formation of dry spots, where liquid flow is insufficient for effective mass transfer.

3.5 Efficiency Comparison:

Due to their specific design, pall rings offer improved efficiency in mass transfer compared to traditional random packings like Raschig rings. The increased surface area and enhanced geometric features facilitate better liquid distribution and lower pressure drop. So pall ring's efficiency higher than raschig ring.

4. Applications in Industry

4.1 Use of Raschig Rings in Traditional Applications

Raschig rings find use in a range of applications, including absorption, stripping, and distillation columns, but their performance might be considered lower compared to more advanced structured packings. Their simple design and cost-effectiveness make them suitable for processes where high mass transfer efficiency is not a critical requirement. They are often employed in industries dealing with corrosive fluids, where ceramic raschig rings can offer excellent chemical resistance.

4.2 Pall Rings in Modern Industrial Processes

Pall rings, due to their enhanced performance, are preferred in modern industrial processes that demand high mass transfer rates and efficient fluid distribution. Pall rings are commonly used in applications that demand high-performance packing, such as gas absorption, desorption, and distillation, especially in applications where a high surface-to-volume ratio is crucial.Pall rings are also favored in systems that handle large gas volumes, as their design promotes better gas-liquid interaction.

4.3 Suitability for Various Fluid Systems

Both Raschig rings and Pall rings are suitable for a wide range of fluid systems, including gas-liquid, liquid-liquid, and vapor-liquid systems. However, Pall rings are more versatile due to their ability to handle a broader range of flow rates and pressures, making them ideal for more complex processes.

5. Advantages and Disadvantages

5.1 Key Advantages of Pall Rings:

Enhanced Surface Area: The incorporation of windows and struts increases the available surface area for interaction.

Improved Mass Transfer: Efficient gas-liquid contact leads to superior mass transfer capabilities.

Lower Pressure Drop: Pall Rings' geometric design contributes to a reduction in pressure drop, optimizing energy efficiency.

5.2 Key Advantages of Raschig Rings:

Durability: Known for their sturdy construction, Raschig Rings withstand harsh chemical environments.

Versatility: Suitable for a wide range of applications, especially those with less demanding mass transfer requirements.

Proven Track Record: Raschig Rings have a long history of reliability and have been employed successfully in numerous industrial settings.

Pall ring and raschig ring Surface Area and Gas-Liquid Contact Points:

The design of Pall rings gives them a larger surface area and more gas-liquid contact points compared to Raschig rings, making them potentially more suitable for applications requiring high mass transfer efficiency and reaction rates.

5.3 Strengths and Limitations of Pall Rings

Pall rings provide numerous advantages over Raschig rings, including lower pressure drop, higher mass transfer efficiency, and better fluid distribution. However, these benefits come at a higher cost, as Pall rings are more complex to manufacture. Additionally, while Pall rings offer better performance in most applications, they may not be necessary in processes where cost and simplicity outweigh the need for high efficiency.

5.4 Fouling Resistance:

Due to their complex structure, Pall rings typically have better fouling resistance, while the simple design of Raschig rings may be more prone to blockage by contaminants. In situations where fluids containing impurities need to be processed, Pall rings may be more reliable.

5.5 Applicability and Cost:

Pall rings are typically more expensive than Raschig rings, mainly due to their complex structure and manufacturing processes. Therefore, in some budget-constrained applications, Raschig rings may be a more economical choice. However, in applications where high performance is required, the advantages of Pall rings may outweigh cost considerations.

6. Choosing the Right Fit: Pall ring VS Raschig Ring

Pall vs. Raschig Selecting between Pall Rings and Raschig Rings depends on the specific requirements of the application. Pall Rings shine in situations demanding heightened mass transfer efficiency and lower pressure drop, while Raschig Rings offer reliability and versatility in less demanding environments. Ultimately, the choice rests on striking the perfect balance between performance and application needs.

7. Conclusion

In conclusion, the Pall Ring and Raschig Ring each bring a unique set of attributes to the table. Understanding their strengths and optimal applications empowers engineers and industries to make informed decisions, ensuring efficient and effective tower packing for diverse chemical processes. Pall rings and Raschig rings play important roles in chemical engineering, with their respective designs and characteristics providing advantages in different application scenarios. Understanding their pros and cons as well as their range of applicability can help engineers and designers make better choices of packing materials to meet the requirements of processes and production.

more detail about pall ring raschig ring instruction

Our Products:

Ceramic Raschig Ring, Plastic Raschig Ring, metal raschig ring