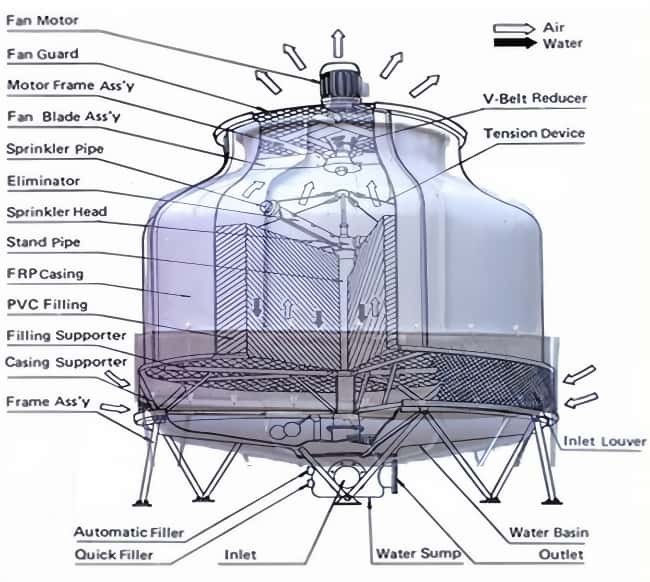

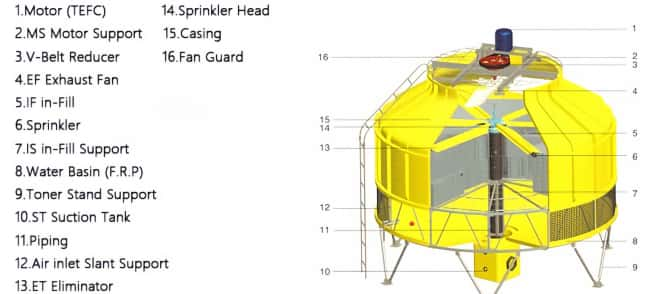

Cooling towers play a pivotal role in a wide range of industrial applications, from power plants to chemical processing facilities and HVAC systems. These towers are designed to cool water or other fluids by facilitating heat dissipation through the process of evaporation. However, the efficiency and effectiveness of cooling towers depend heavily on the individual parts that make up the entire system.

Understanding the essential components of a cooling tower is crucial for anyone involved in its design, operation, or maintenance.

This article provides an in-depth look at the major parts that make up a cooling tower, their functions, types, key considerations, and how they contribute to the overall performance and efficiency of the system.

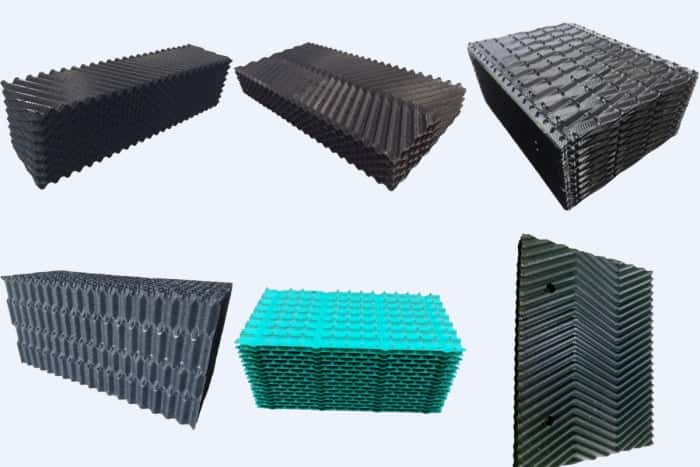

1. Cooling Tower Fill

Function: The cooling tower fill is one of the most important components in terms of maximizing the heat exchange process. Its primary function is to provide a large surface area over which the water can spread, allowing more water to come into contact with the cooling air. This increases the rate of evaporation, enhancing the cooling efficiency of the system.

Types of Fill:

- Sheet Fill: Sheet fills are typically made from durable materials like PVC or plastic. These sheets are stacked or arranged in a crisscross pattern to create a large surface area. The water flows over these sheets in thin films, promoting faster evaporation.

- Honeycomb Fill: Honeycomb fills are structured with a cellular pattern that maximizes surface area and improves thermal performance. These fills are compact, making them suitable for high-efficiency, energy-saving applications, especially in smaller systems.

- Splash Fill: This type of fill creates water droplets by "splashing" the water into the air, which maximizes the heat transfer. It’s typically used for applications with high thermal loads.

Key Considerations:

- Material Selection: The material of the fill must be durable, resistant to corrosion, and capable of withstanding long-term exposure to water, chemicals, and UV radiation.

- Surface Area: The larger the surface area of the fill, the more efficient the heat exchange process will be, reducing the overall energy consumption of the system.

2. Cooling Tower Fan

Function: The fan is essential in circulating air throughout the cooling tower to aid the evaporation of water. By pushing or pulling air through the system, the fan creates the airflow necessary to remove the heat absorbed from the water. Without this airflow, the heat exchange process would be significantly reduced, causing the cooling tower to operate inefficiently.

Types of Fans:

- Axial Fans: These fans are designed to move large volumes of air at moderate pressure. They are commonly used in forced-draft or induced-draft cooling towers where high airflow is needed over large areas.

- Centrifugal Fans: These fans operate under higher pressure and are typically used in large-scale industrial cooling towers that require more robust airflow management, especially in high-pressure systems.

Key Considerations:

- Fan Size: The size and type of the fan must be chosen based on the cooling tower’s required airflow and pressure specifications.

- Material: The fan blades are often made from corrosion-resistant materials like aluminum alloys or high-density plastic to withstand the effects of water mist and environmental conditions.

3. Cooling Tower Water Pump

Function: Water pumps are used to circulate water through the cooling tower system. These pumps bring the heated water from the bottom of the tower to the top, where it is then distributed over the fill media to begin the cooling process. Without an efficient pump, the cooling tower would not be able to operate at full capacity.

Types of Pumps:

- Vertical Pumps: These pumps are ideal for large cooling towers and are designed to move large volumes of water at high pressures. They are often installed in vertical orientation for better space efficiency.

- Horizontal Pumps: More commonly used in smaller systems, horizontal pumps provide lower flow rates but are easier to install and maintain.

Key Considerations:

- Flow Rate: The pump’s flow rate must match the cooling tower’s design specifications. Insufficient flow can cause inadequate cooling, while excessive flow can lead to inefficiency.

- Material Durability: Pumps are often exposed to corrosive water and chemicals. Materials like stainless steel or composite materials should be selected for their resistance to corrosion and wear.

4. Drift Eliminator

Function: drift eliminators are designed to reduce the amount of water vapor (drift) that escapes from the cooling tower into the atmosphere. They trap water droplets and return them to the system, ensuring that the water is efficiently reused, thereby conserving water resources and improving the environmental footprint of the cooling tower.

Design:

- Shape: Drift eliminators typically consist of a series of baffles or mesh structures that force water droplets to collide with surfaces and fall back into the tower.

- Material: Most drift eliminators are made from UV-resistant PVC or polyethylene, ensuring that they withstand the harmful effects of sunlight exposure.

Key Considerations:

- Efficiency: The drift eliminator’s design must balance airflow and water retention. If it restricts too much airflow, it can reduce the tower’s cooling capacity.

- Corrosion Resistance: Given the exposure to water and chemicals, materials that resist corrosion and degradation are essential for ensuring long-lasting performance.

5. Cooling Tower Structure

Function: The structure of the cooling tower serves as the physical foundation that holds all the components together. It provides stability and ensures the tower can withstand environmental stresses such as wind, temperature fluctuations, and mechanical vibrations. The tower structure also supports the internal components, including the fill, fan, and pump systems.

Materials:

- Steel: Steel is often used for the framework because of its strength and ability to handle heavy loads.

- Concrete: Concrete is commonly used in larger towers for its durability and ability to withstand high heat.

- Fiberglass: For smaller systems or towers that require more flexibility and corrosion resistance, fiberglass is a popular choice.

Key Considerations:

- Corrosion Resistance: Since cooling towers are frequently exposed to high humidity and chemical treatments, corrosion resistance is a key factor in material selection.

- Structural Integrity: The tower must be designed to handle not only the weight of the equipment but also the pressure generated by water and airflow.

6. Drive System

Function: The drive system powers the fans and pumps within the cooling tower. It typically includes an electric motor, gearbox, and associated drive shafts. The drive system ensures that the fans rotate at the appropriate speeds to maintain airflow, and the pumps circulate water efficiently.

Types:

- Electric Drive Systems: These systems are the most common in modern cooling towers, providing efficient, reliable power for both fans and pumps.

- Mechanical Drive Systems: In certain high-stress applications, mechanical systems provide better stability and long-term durability than electric drives.

Key Considerations:

- Motor Size: The motor must be sized correctly for the load requirements of the cooling tower. Over-sized motors can waste energy, while under-sized motors may fail to meet performance demands.

- Durability: The drive system must be able to function efficiently in high-humidity and corrosive environments, which can wear down components over time.

7. Cold Water Basin

Function: The cold water basin serves as the collection point for the cooled water after it has passed through the cooling tower. It ensures that the cooled water is available for reuse or for redistribution back to the industrial system.

Design:

- Capacity: The cold water basin must be large enough to handle the volume of water produced by the cooling tower.

- Corrosion Resistance: Materials used for the cold water basin should be resistant to corrosion, especially in systems where water quality may vary.

8. Cooling Tower Spray Nozzles

Function: Cooling tower nozzles distribute water evenly over the fill media to ensure uniform cooling. These nozzles are designed to break the water into droplets or a fine mist, increasing the surface area available for heat exchange.

Materials: Typically made from corrosion-resistant plastics like PVC or glass-filled nylon, cooling tower nozzles are designed to withstand harsh environmental conditions.

Key Considerations:

- Flow Control: The nozzles must be designed to ensure even distribution of water to optimize heat transfer.

- Maintenance: Nozzles must be easy to clean and maintain, as clogging or blockages can reduce cooling efficiency.

9. Cooling Tower Air Inlet Louvers

Function: Cooling tower Air Inlet louvers are designed to control the airflow into the tower. They prevent debris from entering the system and also help to direct the airflow in a manner that maximizes cooling efficiency.

Materials: Louvers are usually made from durable materials like fiberglass or metal, which are resistant to UV radiation and corrosion.

Key Considerations:

- Airflow Control: The louver design should balance the need for maximum airflow with the prevention of water splash-out and debris ingress.

- Durability: Materials used for louvers must be resistant to the harsh environmental conditions found in cooling towers.

10. Cooling Tower Motor

Function: The motor drives the fan of the cooling tower, ensuring that air is circulated effectively to promote evaporation and heat transfer.

Key Considerations:

- Motor Power: The motor's power must be sufficient to drive the fans at the required speed, depending on the size of the cooling tower and the airflow needed.

- Energy Efficiency: Motors should be selected based on their energy efficiency to minimize operational costs.

Conclusion

Cooling towers are complex systems that rely on the efficient operation of multiple components working together to maximize heat dissipation and energy conservation. Proper design, selection, and maintenance of these components ensure that the cooling tower operates efficiently, conserves water, and reduces energy consumption. By understanding the importance of each part, operators and engineers can optimize the performance of cooling towers in various industrial applications, leading to reduced costs, improved sustainability, and greater reliability.