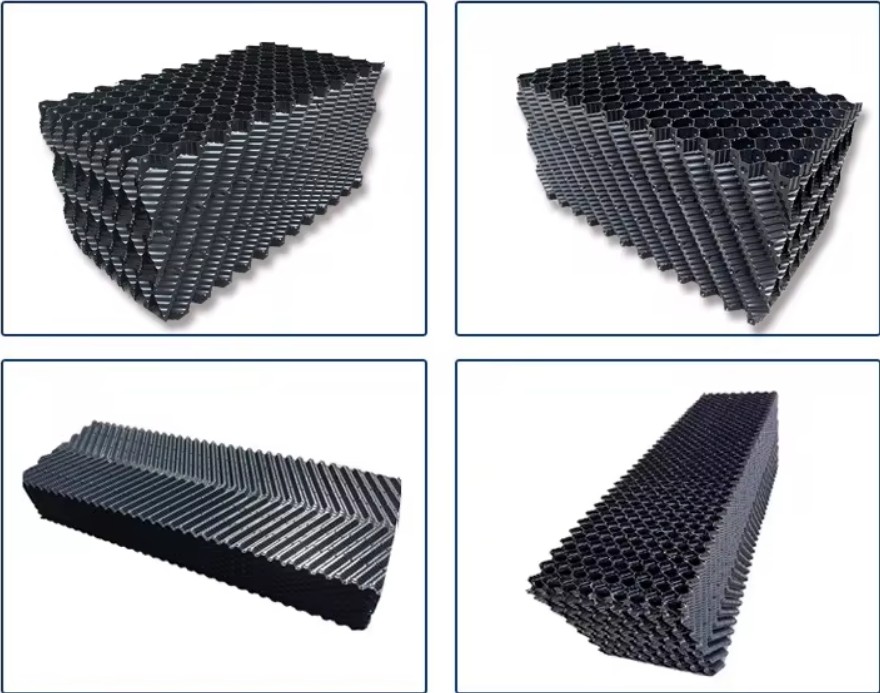

PVC Cross-Fluted Fills, also referred to as Block PVC Fluted Fills or cross-corrugated fills, represent the highest performance film fill available, offering exceptional water redistribution properties. These cooling tower fills enhance water distribution by dividing the water stream as it flows down through the fill pack. The CF1900 design splits the water stream eight times over a 12-inch (305 mm) vertical drop.

This fill type achieves high thermal performance (high KaV/L) while maintaining a low pressure drop, thanks to its engineered microstructure and adherence to the highest manufacturing standards.

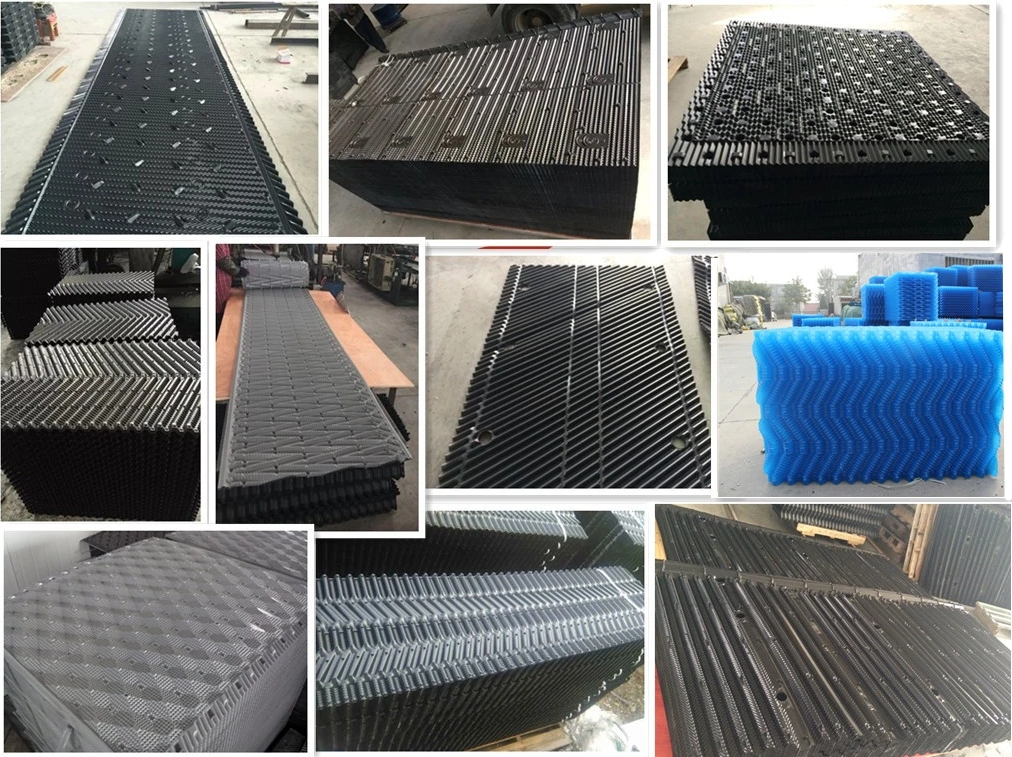

The PVC compounds used in these fills exhibit excellent resistance to weather exposure and are highly resistant to chemical degradation from alkalis, acids, greases, fats, oils, and biological threats. Additionally, PVC boasts a superior fire rating due to its self-extinguishing properties and complies with or exceeds Cooling Tower Institute Standard 136. For specialized applications, HPVC (high-temperature), PP (polypropylene), and ABS plastics are also available.

Features of PVC Cross-Fluted Fills

Features of PVC Cross-Fluted Fills

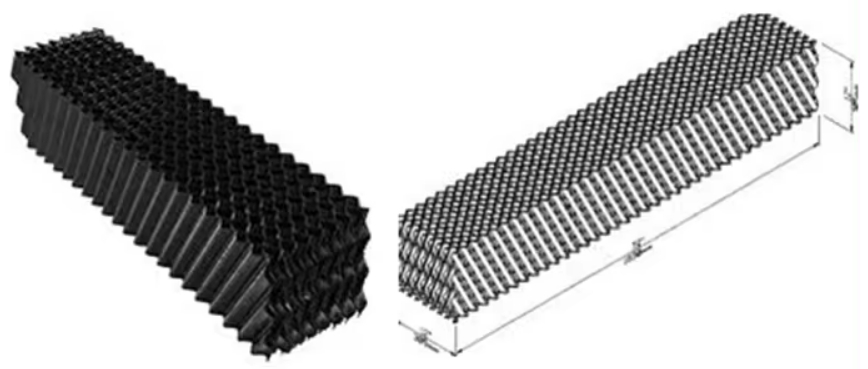

High-performance trickle fill installations are defined by their exceptional mechanical strength. This strength arises from two key factors: robust and stable connection technology, and a uniquely designed fill structure. The thick edges of the fill provide significantly greater strength compared to older flat film constructions.

The CF-19 circular fill can be manufactured in nearly any strength class, up to 80 kg/m³, allowing for optimal design tailored to specific customer requirements. We prioritize environmental compatibility (solvent-free) and ensure simple, reliable processing through our proprietary welding technology, all while meeting stringent fire safety standards.

Our custom-developed welding machines enable us to produce individual fills suitable for permanent use, as well as for on-site fabrication. With an optimized fill design that offers a free volume greater than 97%, these fills are effective for both clean and slightly contaminated water.

Common applications include cooling towers, agriculture, and wastewater management. Please reach out to us for assistance in selecting the right type for your needs.

how Block PVC Fluted Fills work

PVC cross-fluted fills are used in cooling towers to enhance the heat exchange process. Here's how they work: Structure: The fills are made of PVC and have a cross-fluted design. This design increases the surface area for heat exchange while promoting better air and water distribution.

Structure: The fills are made of PVC and have a cross-fluted design. This design increases the surface area for heat exchange while promoting better air and water distribution.

Heat Transfer: As hot water from the cooling system flows over the fills, it spreads out due to the fluted structure. This maximizes the contact area with the air flowing through the tower.

Airflow: Air is drawn into the cooling tower, typically by fans. As the air moves through the fills, it absorbs heat from the water, causing the water to cool down.

Specification of PVC Cross-Fluted Cooling Tower Fills

Products | Surface Area | Sheet Spacing | Flute Angle Degrees (˚) | Sheets Per Ft | Pack Sizes Minimum D/W/L | Pack Sizes Maximum D/W/L | Pack Sizes Standard D/W/L | Nominal Gauge | Dry Weight |

ft2/ft3 | inches | inches | inches | inches | mils | lbs/ft3 | |||

CF1200 | 69 | 0.46 | 30 | 26 | D: 3.9 | D: 11.8 | D: 11.8 | 8 or 10 | 2.4 or 2.8 |

W: 6 | W: 12 | W: 12 | |||||||

L: 12 | L: 120 | L: 48, 72, 96, 120 | |||||||

ThermaCross | 47 | 0.75 | 22 | 16 | D: 5.9 | D: 23.625 | D: 11.8 or 23.625 | 10 or 15 | 1.7 or 2.4 |

W: 5.9 | W: 23.625 | W: 11.8 | |||||||

L: 12 | L: 144 | L: 72, 96, 120 | |||||||

CF1900 | 48 | 0.75 | 31 | 16 | D: 6 | D: 24 | D: 12 or 24 | 10 or 15 | 1.7 or 2.4 |

W: 6 | W: 24 | W: 12 or 24 | |||||||

L: 12 | L: 12 | L: 48, 72, 96, 120 | |||||||

CF1900SS | 48 | 0.75 | 27 | 16 | D: 12 | D: 12 | D: 12 | 10 or 15 | 1.7 or 2.4 |

W: 6 | W: 12 | W: 12 | |||||||

L: 24 | L: 72 | L: 48, 72 | |||||||

CFS3000 | 31 | 1.18 | 30 | 10 | D: 12 | D: 24 | D: 24 | 15 | 1.7 |

W: 6 | W: 24 | W: 12 or 24 | |||||||

L: 12 | L: 12 | L: 48, 72, 96, 120 |

Material: PP, PVC, HPVC.

Surface area (m2/m3): 102, 157.5, 226.

Sheet spacing: 11.7 mm, 19 mm, 30.5 mm for counter flow towers, and 12.5 mm for cross flow towers.

Flute angle: 27°/30° for counter flow towers, and 15°/45° for cross flow towers.

Depth: 100-610 mm.

Width: 153-610 mm.

Length: 305-3660 mm.

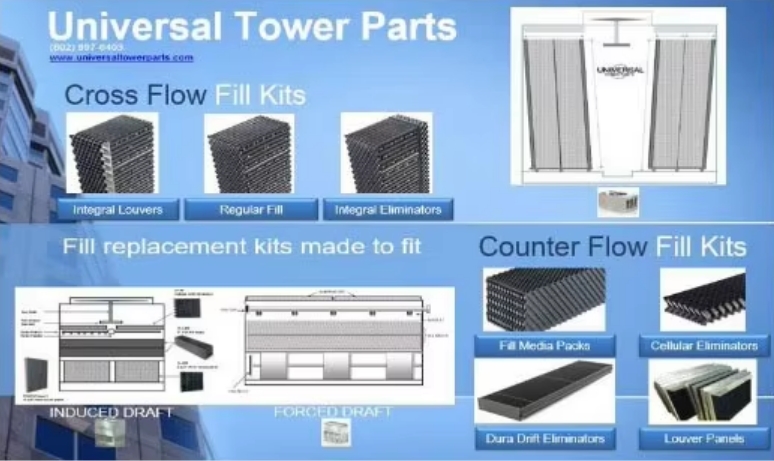

Applications of Different PVC Fluted Fills for Cooling Towers

CF1900:

The CF1900 is a widely used option for both field-erected and factory-assembled counterflow cooling towers, and it can also be utilized in crossflow towers. It is primarily designed for HVAC and light industrial applications where water has low levels of total suspended solids.

CF1900SS:

The CF1900SS features high-performance structured packing made from 304L stainless steel, ideal for special applications where extreme temperatures or flammability issues limit the use of polymer materials. This fully engineered product boasts 228 welds per cubic foot (8050/m³), ensuring precise uniformity in sheet and pack dimensions.

CF1200:

The CF1200 is designed for use in factory-assembled counterflow towers, specifically in HVAC and light industrial applications. It serves as a distribution pad in depths of 3.9 inches (100 mm) and 5.9 inches (150 mm) where the water contains very low levels of total suspended solids. Its beveled tips promote effective drainage, resulting in a lower pressure drop.

CFS3000:

For use in the same applications as CF1900, the larger channels of CFS3000 decrease fouling potential in lower quality water

Summary:

PVC cross-fluted fills in cooling towers work by increasing the surface area for heat exchange, enhancing the effective contact between water and air to improve cooling efficiency. The water film on the surface evaporates, further reducing the water temperature. PVC material is resistant to corrosion, making it suitable for long-term use. Our factory has many years of production experience, and we welcome new and old customers to contact us at any time.

Our factory has many years of production experience, and we welcome new and old customers to contact us at any time.