In the modern world of infrastructure and civil engineering, the shift toward more sustainable, corrosion-resistant, and cost-effective materials has led to the rising popularity of PVC sheet piles, and interlocking sheet piles. These materials are not only efficient in supporting excavation and soil retention, but they also offer significant resistance to water seepage. This article explores the composition, advantages, installation methods, and diverse applications of these innovative seawall materials across various industries.

1. What Are PVC Sheet Piles?

PVC (Polyvinyl Chloride) sheet piles also named plastic sheet piling, and interlocking sheet piles are manufactured using high-density polyvinyl chloride. Vinyl sheet pile is a new type of high strength composite material, which is extruded by a special process. The shape of the sheet pile is designed according to the principle of physics, adopts large moment of inertia section design, and is combined with multi-direction concave and convex joints to become a new type of continuous, high-strength and high lateral bending resistance green bank protection and flood control structure. Ecological sheet pile can effectively replace traditional materials, such as steel sheet pile, concrete sheet pile or wood sheet pile. It is widely used because of its excellent performance parameters and low investment cost.

2. Types and Profiles of Plastic Sheet Piling

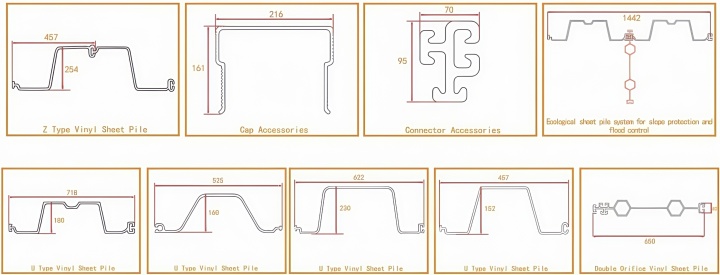

Plastic sheet piles are available in several profiles:

- Z-profile: High bending strength for deep installations

- U-profile: Balanced between strength and flexibility

- Flat panels: Used for non-structural partitioning or low-pressure environments

Additionally, reinforced types exist, such as fiberglass-reinforced PVC sheet piles, enhancing mechanical properties while retaining corrosion resistance. Type of Ball and socket connectors for flexibility; Omega interlocks for tight sealing. Double-interlock systems for high-strength applications. These interlocks prevent water seepage and enhance the structural coherence of the sheet wall, making them ideal for load-bearing and water-retaining applications.

Vinyl(PVC) Sheet Pile Data Sheet

| Project | Unit | Numerical Value |

|---|---|---|

| Density | g/cm3 | ≥1.42 |

| Tensile Strength | MPa | ≥42 |

| Bending Strength | MPa | ≥65 |

| Notched Impact Strength of Barrel | kJ/M2 | ≥6 |

| Hardness | Shaw D | ≥79 |

3. Advantages of PVC and Plastic Sheet Piling

- Durable 50+ years design life.

- Does not rot or rust.

- Manufactured by modified plastic.

- UV resistance.

- Lightweight and easy installation.

- Withstand the influence of most chemicals.

- Not affected by salt water.

- Not affected by ocean organisms.

- Reduce the impact on natural resources.

- Not toxic coatings.

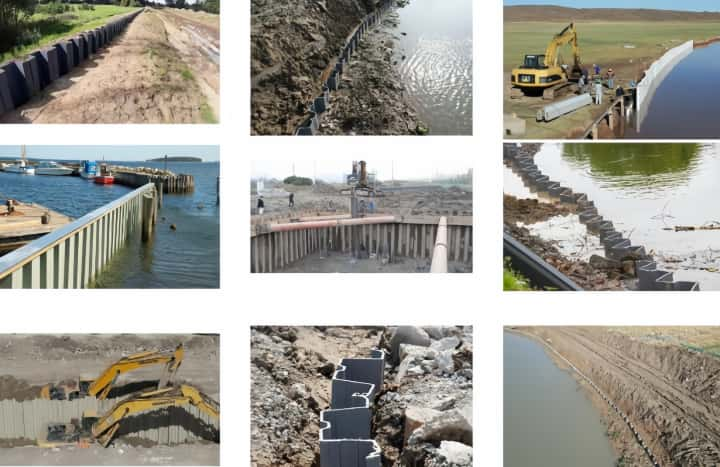

4. Applications of Plastic and Interlocking Sheet Piles

| Application Category | Application Description |

|---|---|

| Light Marine Structures | Used for constructing marine structures such as coastal bulkheads, seawalls, tide walls, breakwaters, jetties, groins, and other marine structures, with superior corrosion resistance, aesthetic appearance, and ease of installation. |

| Cut-Off & Containment Systems | Widely used for groundwater cut-off, chemical containment, fluid seepage barriers, and protection of foundation structures, offering excellent sealing performance and corrosion resistance. |

| Flood Protection | Used for flood walls, levees, and dam stabilization, as well as pipe protection, providing an environmentally friendly alternative with superior corrosion resistance and long service life. |

| Water Control Structures | Used for water flow control structures in ponds, drainage channels, and rivers, including water flow diversion walls, weirs, pond linings, agricultural channel linings, and mining drainage systems. |

| Retaining Wall Structures | Used for soil and water retention, including both temporary works like cofferdams, diaphragm walls, and foundation support, as well as permanent structures like quay walls, bridge abutments, and underground storage tanks. |

| Erosion Control | Used for shoreline and water boundary protection, including beachfront protection, coastline protection, road protection, and bulkhead construction, with attractive appearance, lightness, and durability. |

| Revetment Works | Used as barriers against scouring or undermining from tidal impacts, often combined with rip-raps or used to contain rocks and boulders, providing additional security to marine facilities and coastlines. |

| Embankment Works / Road Construction | Ideal for constructing embankment works, coastal roads, jetties, or elevated walkways, reducing the volume of backfill material required, preventing liquefaction, and optimizing the use of limited space. |

5. Installation Techniques for PVC Sheet Piles

Installation methods vary depending on soil conditions and project size. Vibratory hammers are ideal for sandy or loose soils, Water jetting for cohesive or clay soils, Silent press-in machines for urban or noise-sensitive zones.

General installation process is as follows:

- 6.1 Site Preparation: Clear and level the installation area, then mark the exact positions where each pile will be driven.

- 6.2 Pile Driving: Use a vibratory hammer or suitable driving equipment to insert the PVC sheet piles into the ground.

- 6.3 Interlocking Connection: Securely join adjacent piles through their interlocking edges to ensure structural continuity.

- 6.4 Final Inspection & Backfilling: Check the alignment and verticality of the installed piles. Once confirmed, proceed with backfilling to provide stability and support.

Proper alignment, interlock sealing (using sealing tape or hydrophilic rubber), and toe-in anchoring are crucial for structural performance.

6. Cost Analysis and Lifecycle Economics

Though the upfront cost of plastic sheet piling may be slightly higher than timber or untreated steel, long-term savings are significant:

- Lower maintenance

- Longer lifespan (30–50 years)

- Minimal repair costs

- No coating or corrosion treatment needed

7. Environmental and Regulatory Compliance

Plastic sheet piling solutions often align with:

- LEED certification goals

- ISO 14001 environmental standards

- EPA stormwater containment guidelines

Their inert chemical profile ensures no leaching or pollution of soil and groundwater.

8. Choosing the Right Sheet Pile for Your Project

Factors to consider:

- Soil type: Clay vs sandy vs rocky

- Water conditions: Tidal exposure, pH levels, chemical content

- Load requirements: Structural vs non-structural walls

- Aesthetic demands: Color, surface finish, landscape integration

Always consult with geotechnical engineers and certified suppliers to determine optimal profiles and materials.

9. Frequently Asked Questions (FAQs)

- Q1: How long do PVC sheet piles last?

- Q2: Can plastic sheet piling be reused?

- Q3: Are interlocking sheet piles waterproof?

- Q4: Can PVC sheet piles be installed in winter?

- Q5: Are there fire risks with PVC piles?

Typically 40–50 years with minimal maintenance.

Yes, many systems are reusable in temporary works.

They are highly resistant to seepage when properly sealed.

Yes. They retain flexibility and do not become brittle in cold climates.

Standard formulations are fire-retardant and meet safety codes.

10. Contact Us for More PVC Sheet Pile Solutions

As a professional manufacturer of PVC sheet piles, we are dedicated to providing high-quality, environmentally friendly, and durable construction materials to our global customers. Our plastic sheet seawalls are widely used in marine engineering, infrastructure projects, environmental protection, and more.

Whether you are a new client or a long-term partner, we warmly welcome collaboration with you. Our technical team will provide tailored products and expert installation support based on your project needs, ensuring the success of each project. By choosing our products, you not only gain long-term structural stability but also achieve higher cost-efficiency and environmental sustainability.

Please feel free to contact us for more information about PVC sheet piles and to receive your exclusive quotation. We look forward to working together with you to provide high-quality solutions for your projects.