random packing is a crucial element in many industrial processes, particularly in separation technologies like distillation, absorption, and scrubbing. Its role in improving mass transfer between gases and liquids has made it indispensable in industries ranging from chemical processing to water treatment. Unlike structured packing, which is carefully layered, random packing consists of irregularly shaped materials that are randomly dumped into a column, maximizing surface contact and fluid mixing.

This comprehensive guide explores the history, types, working mechanisms, and the pros and cons of random packing, offering insights into how it can be effectively used in various industries. By examining the materials used, the selection criteria, and the applications of random packing, this guide aims to provide a detailed resource for engineers, designers, and professionals seeking to optimize their systems.

1. What is Random Packing?

Random packing refers to the use of small, irregularly shaped materials—such as rings, saddles, and spheres—within packed columns to enhance the contact between gas and liquid phases. By maximizing the surface area within a column, random packing increases mass transfer efficiency, making it particularly useful for separation processes like distillation, absorption, scrubbing, and stripping.

Key Characteristics:

- Random Distribution: The packing material is randomly arranged, promoting fluid mixing and maximizing surface contact.

- Applications: Used extensively in industries such as chemical processing, water treatment, and air pollution control.

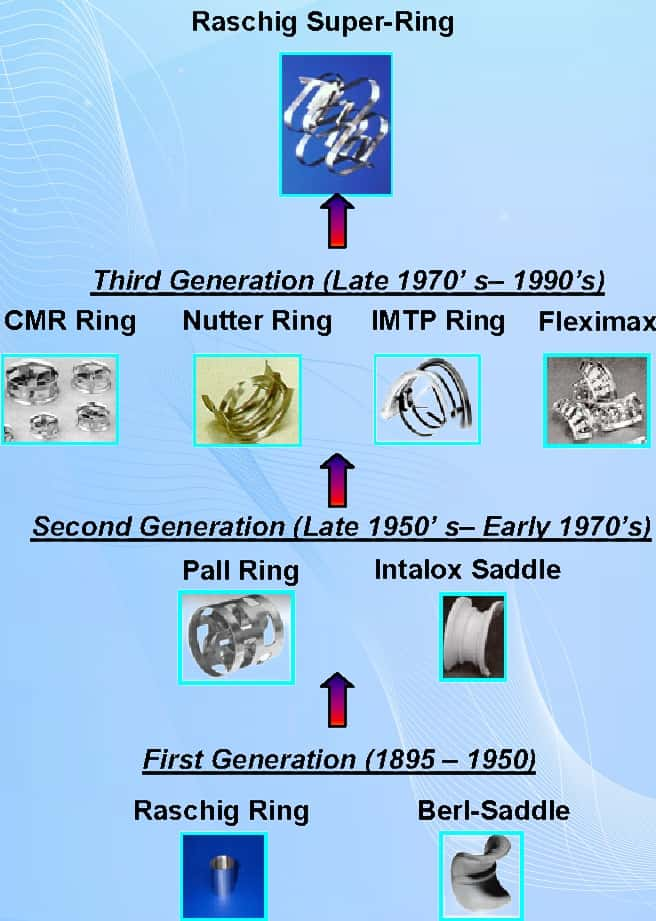

2. History of Random Packing

The development of random packing traces back to the early 20th century when Friedrich Raschig introduced the Raschig ring, one of the earliest types of random packing, around 1914. This simple cylindrical shape laid the foundation for mass transfer technologies, particularly in distillation and absorption processes. However, its limited surface area and efficiency led to the development of more advanced designs over the years.

- 1950s: The Pall ring emerged as an improved version of the Raschig ring, with additional openings to increase surface area and improve fluid flow.

- 1960s: The introduction of saddle designs (Berl and Intalox saddles) improved efficiency in fluid distribution.

- 1970s to Present: Newer designs such as Tri-Packs and Hi-Flow Rings optimized the balance between surface area, pressure drop, and efficiency.

These advancements, alongside innovations in materials like plastics and ceramics, have transformed random packing into a versatile solution used across a wide range of industries.

3. What Are the Common Types of Random Packing?

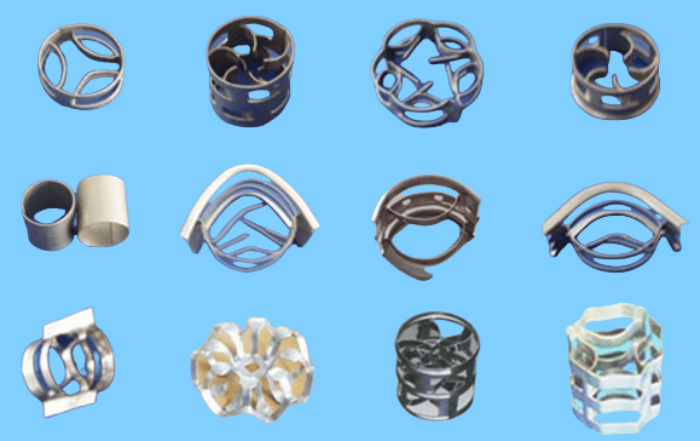

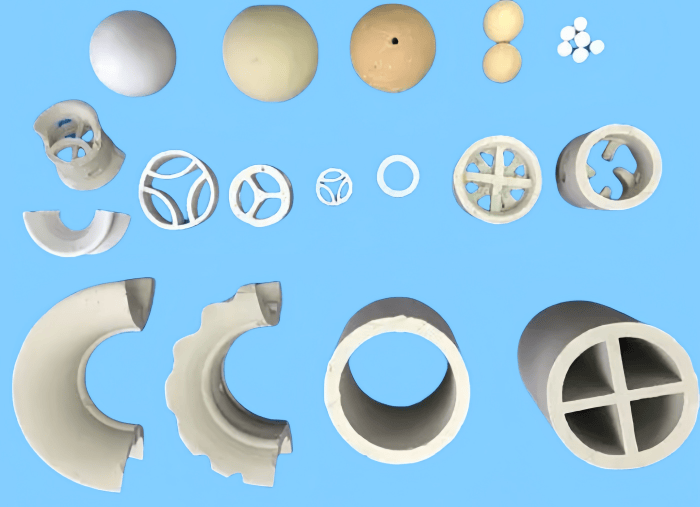

Several different types of random packing exist, each designed to improve specific aspects of fluid flow and mass transfer. Common types include:

3.1 Raschig Rings

These early cylindrical rings, though simple, offer limited efficiency and have largely been replaced by newer designs.

3.2 Pall Rings

An improvement over Raschig rings, Pall rings feature additional side openings, increasing surface area and improving fluid distribution. Available in metal, plastic, and ceramic.Pall ring is a type of random packing that improves upon the Raschig ring by adding openings on its sides, which increases surface area and enhances fluid distribution. It reduces pressure drop and is used in various industries, including distillation, gas scrubbing, and water treatment. Pall rings are available in materials like plastic, metal, and ceramic, offering versatility for different applications.

3.3 Saddle Rings (Berl and Intalox)

Curved shapes that enhance gas-liquid interaction, especially in metal form (IMTP), providing improved capacity and lower pressure drop.Berl saddle, introduced as a first-generation packing material between 1907 and 1950, was a simple design that engineers later refined. Intalox saddles, an evolution of this concept, are a form of random packing specifically crafted to enhance surface area and optimize fluid flow. Their distinctive saddle shape improves gas and liquid distribution while lowering pressure drop, thereby boosting mass transfer efficiency. Available in materials such as ceramic, plastic, and metal, Intalox saddles find widespread use in processes like distillation, absorption, and gas scrubbing. Their advanced design minimizes flow resistance, making them suitable for high-capacity, high-efficiency applications.

3.4 Super Saddles

A modern version of saddle rings, offering greater surface area and more efficient mass transfer.Super saddles are an advanced version of traditional saddle-type random packing. Their larger, more open saddle-shaped design increases surface area and improves gas and liquid contact, enhancing mass transfer efficiency. Made from materials like ceramic and plastic, super saddles offer better performance in terms of reducing pressure drop and optimizing fluid distribution. These characteristics make them ideal for use in applications such as distillation, absorption, and gas scrubbing, particularly in systems requiring high efficiency and capacity.

3.5 Tri-Packs

Spherical designs with ribs that ensure even liquid distribution and minimize pressure drop, often used in gas scrubbers.tri-packs are a type of random packing with an innovative design, introduced in the late 1970s. These plastic fill pieces are shaped like open spheres with ribs that are evenly spaced both on the exterior and interior. This unique ribbed structure allows for even liquid distribution, ensuring unimpeded contact between gases and liquids, which maximizes mass transfer efficiency. Tri-Packs work particularly well in applications such as degasifiers, strippers, and scrubbers. Their design also helps minimize blockages and pressure drop, making them a high-performance option in various industrial processes.

3.6 Hi-Flow Rings

Newer designs offering enhanced mechanical strength, optimized efficiency, and lower pressure drops, suitable for environmental and chemical applications.Hi-Flow rings, also known as Hi-Rings, are a type of random packing designed for high efficiency in mass transfer operations. They feature a large void space, low specific gravity, and high physical strength, which contribute to excellent fluid distribution and reduced pressure drop, maximizing gas and liquid interaction. These characteristics make Hi-Flow rings particularly effective in environmental applications, the oil and gas industry, chemical processing, and alkaline chloride systems. Their robust design ensures durability and high capacity, making them ideal for processes like distillation, scrubbing, and absorption in demanding industrial settings.

3.7 Super Raschig Ring

super raschig rings are an advanced type of random packing designed to improve upon the traditional Raschig ring. These rings offer a larger surface area and optimized structure for better gas and liquid contact, enhancing mass transfer efficiency. Their open, cylindrical design with added internal structure reduces pressure drop, increases throughput, and provides greater mechanical strength. Made from materials like stainless steel, ceramic, or plastic, Super Raschig rings are highly resistant to corrosion and thermal stress, making them ideal for applications in distillation, absorption, gas scrubbing, and chemical processing industries where high efficiency and capacity are required.

3.8 Tellerettle Packing Super Raschig Ring

Tellerettle packing also calledTeller Rosette Ring is available in both metal and plastic materials. The metal version consists of twelve small rings arranged radially, while the plastic version may feature ten or a different number of small rings. This unique radial design gives the Teller Rosette Ring a high void fraction, preventing clogging, allowing for greater fluid flow, and minimizing pressure drop. The large gaps between the packing elements hold a significant volume of fluid, extending the liquid's residence time and increasing the contact duration between liquid and gas, which enhances mass transfer efficiency.

4. How Does Random Packing Work?

Random packing enhances mass transfer by increasing the contact area between the liquid and gas phases within a column. The randomly arranged packing material creates voids and channels that allow fluids to pass through, improving mixing and mass transfer.

Mechanisms:

- Surface Area: Irregular shapes maximize the available surface area.

- Fluid Flow: Gas and liquid flow through voids, promoting interaction and separation or contaminant removal.

5. Materials Used in Random Packing

Random packing is available in a variety of materials, each suited to specific industrial applications:

5.1 Metals

Stainless Steel, Aluminum, Carbon Steel: Ideal for high temperatures and corrosive environments. Metals offer excellent mechanical strength and durability.

5.2 Plastics

Polypropylene, PVC: Lightweight, cost-effective, and resistant to many chemicals. Commonly used in lower-temperature applications.

5.3 Ceramics

Alumina and Carbon-based Ceramics: Best suited for high-temperature and highly corrosive environments. These materials are highly resistant to chemical attack but are more brittle.

5.4 Carbon

Carbon Raschig Rings: Used in highly acidic or alkaline environments, they offer strong resistance to chemical corrosion and thermal shock.

6. Random Packing Selection Criteria

Selecting the right random packing involves several important factors:

6.1 Surface Area

Packing with a larger surface area allows for more efficient mass transfer, which is critical in separation processes such as distillation and scrubbing.

6.2 Pressure Drop

A lower pressure drop reduces energy consumption, which is important for operational efficiency.

6.3 Wetting Characteristics

The ability of packing material to maintain wetness is crucial for effective gas-liquid interaction.

6.4 Material Compatibility

Packing materials should be chosen based on their compatibility with the chemicals and temperatures in the process.

6.5 Cost Considerations

Costs can vary greatly depending on the material, the complexity of the packing, and the application.

7. What Are the Advantages of Using Random Packing?

Random packing offers several benefits that make it a popular choice in many industrial processes:

7.1 Cost-Effective

Generally more affordable than structured packing, both in terms of material costs and installation.

7.2 Ease of Installation

Random packing can be easily poured into a column without the need for precise arrangement, reducing installation time and labor costs.

7.3 Wide Operating Range

Suitable for various applications, including distillation, absorption, and scrubbing, across different flow rates and fluid types.

7.4 Low Pressure Drop

The open structure of random packing allows fluids to move through the column with less resistance, minimizing energy consumption.

7.5 Corrosion Resistance

Certain materials, like stainless steel and ceramics, are highly resistant to chemical corrosion, extending the lifespan of the packing.

7.6 Enhanced Mass Transfer

The irregular arrangement of the packing material increases the surface area for fluid interaction, boosting mass transfer efficiency.

8. Disadvantages of Random Packing

While random packing offers several advantages, there are some potential drawbacks to consider:

8.1 Higher Pressure Drop (compared to structured packing)

Random packing can result in higher pressure drops in some applications, increasing operational costs.

8.2 Lower Efficiency

Random packing generally offers lower separation efficiency compared to structured packing, which has a more controlled and ordered arrangement.

8.3 Fouling Issues

The irregular shapes in random packing may trap solid particles, leading to fouling over time.

8.4 Fragile Materials

Some materials, like ceramics, are fragile and can break during installation or operation, increasing maintenance costs.

9. Where is Random Packing Used?

Random packing is used across various industries that require gas-liquid interaction:

9.1 Chemical Processing

Used in distillation, absorption, and stripping towers for the separation and purification of chemical components.

9.2 Water Treatment

Employed in degasification and aeration processes, contributing to water purification and oxygenation.

9.3 Air Pollution Control

Installed in scrubbers to remove particulates and harmful gases from industrial exhaust streams.

9.4 Petrochemical Industry

Applied in refining operations to separate hydrocarbons and purify natural gas streams.

9.5 Biological Filtration

Used in wastewater treatment for biological filtration, enhancing the treatment of water in industrial and municipal systems.

10. How Do You Choose the Right Random Packing for an Application?

Several factors must be considered when choosing the right random packing for a specific application:

10.1 Surface Area

Larger surface areas increase the contact between gas and liquid, improving mass transfer efficiency.

10.2 Pressure Drop

Lower pressure drops result in reduced energy consumption, crucial for systems that need to operate efficiently.

10.3 Material Compatibility

The material should be selected based on the chemical and thermal properties of the fluids in the system.

10.4 Size

Larger packing elements create more void space, reducing pressure drop but potentially lowering separation efficiency.

10.5 Corrosion and Fouling Resistance

Materials like ceramics or metals are ideal for environments with corrosive chemicals or where fouling is a concern.

11. Can Random Packing Be Reused?

Yes, random packing can often be reused depending on its condition after use. The following factors affect reusability:

11.1 Material Condition

Metal and plastic packings are typically more durable and can withstand multiple cycles, while ceramics are more fragile.

11.2 Cleaning and Maintenance

Fouled packing may need to be cleaned before reuse, especially if particulate buildup has occurred.

11.3 Wear and Tear

Over time, chemical exposure, mechanical stress, and thermal cycles may degrade the packing material, reducing its efficiency and lifespan.

12. Conclusion

Random packing remains an essential technology in various industries, offering cost-effective and versatile solutions for gas-liquid separation. While it may not always match the efficiency of structured packing, its ease of installation, material variety, and durability make it a preferred choice for many applications. By understanding the types, materials, and proper selection criteria, engineers and designers can optimize the use of random packing to meet their specific industrial needs.