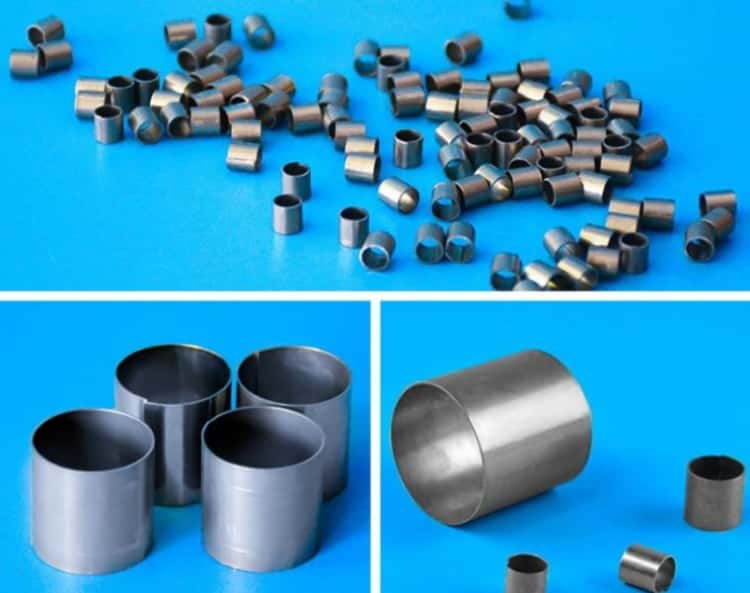

Raschig rings are used in various industrial fields such as chemical engineering, petroleum, and environmental protection, primarily in tower internals. Their design resembles that of ceramic rings, comprising cylindrical structures typically exhibiting a height equal to their diameter. Raschig rings are commonly manufactured from materials like ceramics, metals, or plastics, offering corrosion resistance, durability, and high-temperature tolerance. FYou can gain a comprehensive understanding of raschig ring packing through the following content, which offers insights into various aspects of the raschig packing.

1.Raschig Ring Invention History

Raschig ring packing was pioneered by German chemist Friedrich Raschig during the early 20th century, marking a significant advancement in industrial chemistry. Friedrich Raschig, an esteemed chemical engineer and laboratory technician based in Kassel, Germany, demonstrated a profound interest in refining chemical processes. Establishing his chemical factory at the onset of the 20th century, he embarked on rigorous research and development endeavors aimed at innovating various chemical products and processes.

Its inception dates back to the late 19th and early 20th centuries, a period characterized by a growing demand in the chemical industry for efficient packing materials to optimize reactor performance. Raschig discovered that fabricating cylindrical ring-shaped packing materials, crafted from ceramics, metals, or plastics, significantly augmented the surface area available for gas-liquid phase contact within reactors, thereby enhancing reaction efficiency.

In 1904, Raschig secured a patent for his groundbreaking packing material and proceeded to undertake large-scale manufacturing and distribution from his facility. Rapid adoption ensued, as the Raschig ring packing swiftly became a staple tower packing material across diverse sectors, including chemical engineering and petroleum refining.

Raschig ring packing remains an indispensable component of countless chemical and refining processes, offering chemical engineers a straightforward yet highly effective means to optimize reactor efficiency and performance.

2.Structural characteristics of Raschig rings

Cylindrical Shape: Raschig rings are generally cylindrical in shape, featuring a hollow center and an outer surface with evenly distributed perforations or indentations.

Uniform Size: Raschig ring's height and diameter is the same.They are manufactured to be consistent in size and shape, ensuring uniformity and stability when packed into columns or towers.

High Surface Area: The outer surface of Raschig rings is designed to maximize surface area than other original packed tower media.

Open Structure: Raschig rings have an open structure that allows for unrestricted flow of fluids, minimizing pressure drop and promoting effective mixing within the packed column.

3.Raschig ring packing material selection

Raschig rings can be made from various materials, commonly including ceramics, metals, and plastics. Here's a description of each material along with their advantages and disadvantages:

Ceramic Raschig Rings:

Advantages: ceramic raschig rings offer excellent abrasion resistance and corrosion resistance, suitable for various acidic and alkaline environments. Their smooth surface contributes to improved mass transfer efficiency.

Disadvantages: Ceramic materials are relatively brittle and susceptible to physical impact and thermal shock. Additionally, ceramic rings typically come with higher costs.

Metal Raschig Rings ( SS316L, 304, 321 ):

Advantages: metal raschig rings boast high mechanical strength and durability, with good adaptability to temperature and pressure variations. They usually have lower costs and are easy to process and install.

Advantages: metal raschig rings boast high mechanical strength and durability, with good adaptability to temperature and pressure variations. They usually have lower costs and are easy to process and install.

Disadvantages: Metal rings may be susceptible to corrosion in certain corrosive environments, requiring appropriate metal material selection to enhance corrosion resistance.

Plastic Raschig Rings ( PP, PVDF, CPVC, PE, RPP ):

Advantages: Plastic Raschig rings are lightweight, cost-effective, and exhibit good corrosion resistance. They offer decent resistance to some corrosive media such as acidic or alkaline solutions.

Disadvantages: Plastic rings generally have lower mechanical strength and may require more frequent replacement. Additionally, plastic materials may not be suitable for high-temperature or high-pressure environments.

Disadvantages: Plastic rings generally have lower mechanical strength and may require more frequent replacement. Additionally, plastic materials may not be suitable for high-temperature or high-pressure environments.

The choice of material depends on specific application requirements and operating environments. When selecting materials, factors such as environmental conditions, chemical properties, mechanical strength requirements, and costs need to be considered.

4.Raschig ring size

The diameter of Raschig rings typically ranges from a few millimeters to several centimeters. Common diameter specifications include 6mm, 10mm, 16mm, 25mm, 38mm, 50mm, 76mm, 100mm, etc.

Selecting the appropriate size of Raschig ring packing requires consideration of the following factors:

Tower Diameter: Choose the appropriate size of Raschig rings based on the diameter of the tower to ensure that the packing fills the entire cross-section of the tower and provides sufficient gas-liquid contact surface area.

Fluid Properties: Different sizes of ring packing affect the flow and distribution of fluids in the packing bed. Choose the appropriate size based on the properties of the fluid (such as viscosity, density, etc.) to ensure good fluid distribution and mass transfer efficiency.

Operating Conditions: Consider the operating pressure, temperature, flow rate, and other conditions of the tower when selecting the appropriate size of packing to ensure the durability and stability of the packing material.

Mass Transfer Efficiency Requirements: Smaller sizes of Raschig rings typically offer a larger surface area density, which helps improve mass transfer efficiency. Larger sizes of ring packing may be more suitable for applications with higher flow rate requirements.

In summary, choose the appropriate size of Raschig ring packing based on factors such as tower diameter, fluid properties, operating conditions, and mass transfer efficiency requirements to ensure optimal performance and efficiency of the tower.

5.The stacking way of Raschig rings

The stacking of Raschig rings typically involves random packing or regular packing. Smaller-sized Raschig ring ( 6mm, 10mm, 15mm, 20mm, 30mm,38mm, 50mm ) are usually packed in a random manner. In random packing, the ring fillers are randomly stacked within the tower without a specific arrangement. This packing method helps to provide a larger surface area and better gas-liquid contact. On the other hand, larger-sized Raschig ring ( 100mm, 150mm ) can be packed in a regular manner. In regular packing, the ring fillers are stacked according to certain rules and patterns, often in horizontal layers. This method offers a more stable packing structure and is suitable for specific process requirements. The choice of packing method depends on the specific process requirements, operating conditions, and desired mass transfer efficiency.

6.Characters of Raschig rings

The parameters of Raschig ring packing typically depend on the size of the Raschig rings used. Different sizes of Raschig rings lead to variations in their specific surface area, packing density, and packing method. Technical data sheet as below:

Size | Specific surface | Void | Number | Dry packing factor |

mm | m2/m3 | % | N/m3 | m-1 |

6 | 712 | 62 | 1050 | 5249 |

12.5 | 367 | 64 | 881 | 1903 |

16 | 305 | 73 | 730 | 900 |

19 | 243 | 72 | 801 | 837 |

25 | 190 | 74 | 673 | 508 |

38 | 121 | 73 | 689 | 312 |

40 | 126 | 75 | 577 | 350 |

50 | 92 | 74 | 657 | 213 |

80 | 46 | 80 | 714 | 280 |

100 | 70 | 70 | 700 | 172 |

Above data vary based on different material ( metal, ceramic ,plastic etc )

7.Mass Transfer and Separation Performance

The Raschig ring packing plays a crucial role in mass transfer and separation processes, with the following principles and effects:

Increasing Contact Surface Area: Raschig rings are designed to provide a large surface area, facilitating thorough contact between gases and liquids. The increased surface area enhances opportunities for mutual contact, promoting efficient mass transfer and separation processes.

Facilitating Gas-Liquid Mixing: Within the tower or column, Raschig rings create intricate pathways for gas and liquid flow, inducing turbulent movement that fosters mixing between the two phases. This mixing promotes the transfer of solutes between the liquid and gas phases, thereby accelerating mass transfer processes.

Enhancing Mass Transfer Efficiency: Due to the ample contact surface area and thorough gas-liquid mixing facilitated by the packing, Raschig rings significantly improve mass transfer efficiency. The transfer rate of solute molecules between gas and liquid phases is accelerated, expediting the mass transfer process.

Improving Separation Efficiency: The presence of Raschig ring packing increases opportunities for mutual contact, facilitating mass transfer and separation between different components. During processes such as distillation, extraction, and adsorption, the packing effectively separates various components, enhancing product purity and quality.

Raschig ring packing enhances mass transfer and separation processes by increasing contact surface area, facilitating gas-liquid mixing, and improving mass transfer efficiency, ultimately contributing to enhanced process efficiency and product quality.

8.Application

Widely used in metallurgy, chemical, fertilizer, sulfuric acid, gas, oxygen, pharmacy washing tower, cooling tower, recovery of acid tower, desulfurization tower, drying and absorption tower.Methanol rectifying tower, octanol and octanone separation. The main application areas are used as catalyst support.

Conclusion

After reviewing the content above, we believe that you now have a comprehensive understanding of the design, materials, and application areas of Raschig Rings. As manufacturers of chemical packing materials, if you have any further inquiries or require additional information, please do not hesitate to contact us for consultation!