An RTO, or "Regenerative Thermal Oxidizer", serves as an eco-friendly solution geared towards mitigating industrial emissions, specifically Volatile Organic Compounds (VOCs) and other detrimental gases. Delving into how RTOs function:

Oxidative Phase: This pre-warmed gas is channeled into an oxidation section. Here, at temperatures usually ranging from 760°C to 980°C, VOCs undergo a transformation, breaking down into benign substances—carbon dioxide and water vapor.

Efficient Heat RecoveryEnvironmental FriendlyCost-effective: Versatility in Handling VOC RTOs can treat VOCs of various concentrations, from low to high, by adjusting operating conditions.

As previously mentioned, an RTO is a device used to treat industrial exhaust gases containing Volatile Organic Compounds (VOCs). By heating the exhaust gases to high temperatures, VOCs are oxidized into carbon dioxide and water vapor in the presence of oxygen.A pivotal component of the RTO is its regenerative heat exchanger, typically utilizing specialized ceramic packings. These packings contribute significantly to the thermal efficiency of the system due to their capacity to absorb and release heat effectively.

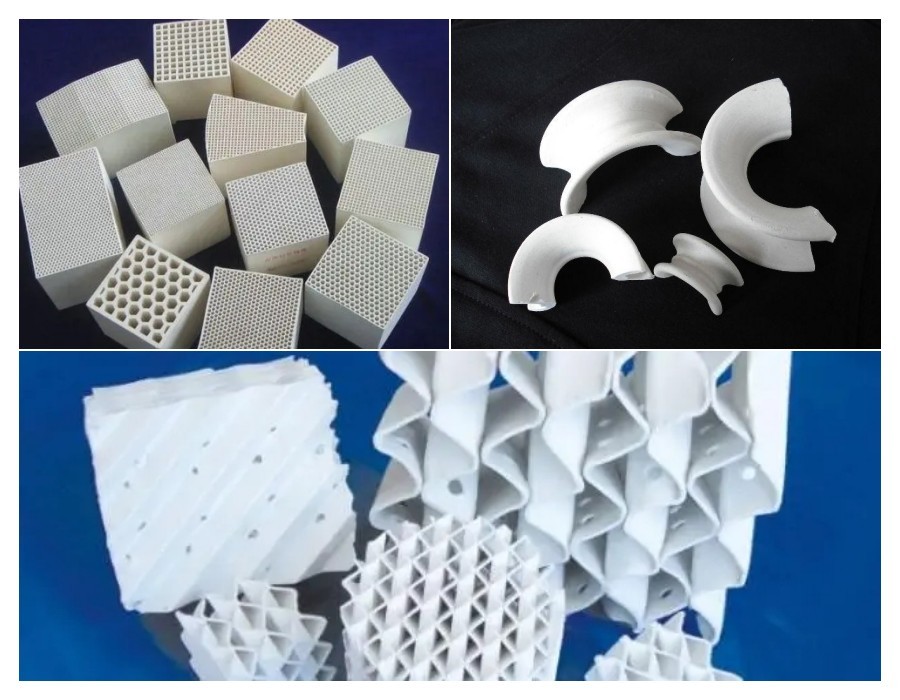

The regenerative heat exchanger portion of an RTO typically employs ceramic saddles packings ,honeycomb ceramics, ceramic structured packing etcThe remarkable thermal stability, corrosion resistance, and longevity of ceramic packings make them an ideal choice for both RTOs and numerous chemical applications.

| Ceramic Saddles | RTO Ceramic Honeycomb |

|  |

| Multi-Layer Ceramic Media | Ceramic Structured Packing |

|  |

In summary, while there might be overlaps in the applications of RTOs and chemical packing, they primarily cater to different objectives and uses. Nonetheless, choosing the right packing, whether in an RTO or a chemical tower, remains critically important.