Tri Packs Tower Packing Media, also known as random packing scrubber balls, is designed for high-performance mass transfer and separation processes. It is particularly effective in pollution control systems for both air and water, providing a large active surface area while maintaining low-pressure drop. Small packing elements are randomly distributed to assist in the separation process, guiding liquids through the packing media into fixed configurations. Tri Pack random packing is among the most efficient types of tower packing, enabling high mass transfer rates. Its higher efficiency also contributes to reduced operating costs.

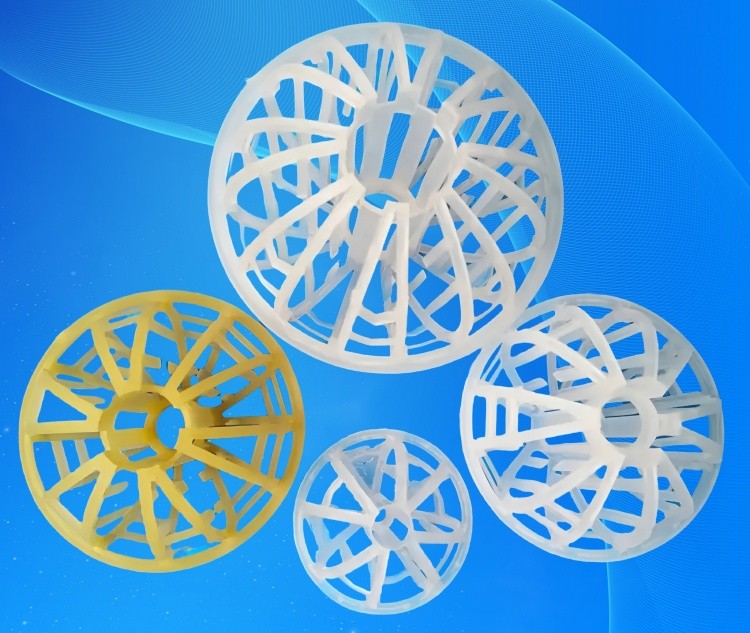

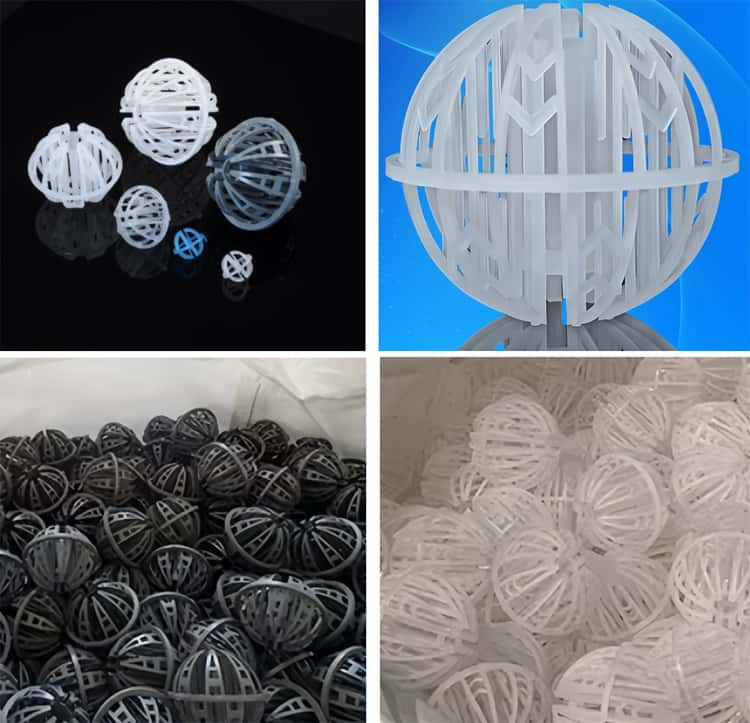

In comparison to older packing types, tri packs — developed in the late 1970s and widely adopted over the following decade — offer several advantages. Their distinctive hollow, spherical design for random packing prevents clumping and settling, while an internal rib structure enhances surface area and ensures even liquid distribution. This improves wetting characteristics without hindering gas-liquid contact. When selecting tower packing media, it’s crucial to assess whether its performance characteristics are suited to your specific application. For instance, the features of Tri Pack packing make it particularly well-suited for strippers, scrubbers, and degasifiers.

Key Features and Benefits of Tri Packs

1. The design of tri-pack tower packing offers several advantages, particularly when compared to alternative options. Some of the key benefits of this packing include:

- 2. Its spherical shape provides a superior surface area-to-void space ratio—greater than that of the Pall Ring—resulting in a high active surface area.

- 3. The unique structure of struts, drip rods, and ribs ensures that Tri-Pack scrubber packing maintains uniform liquid distribution throughout the bed.

- It delivers exceptionally low pressure drops and optimizes operating capacity.

- 4. Tri-Packs prevent issues like compression interlock and dry spots that can lead to air and liquid channeling, common with older packing types, thereby improving efficiency.

- 5. With no flat surfaces or small openings where particles can become trapped, Tri-Packs virtually eliminate nesting and settling, making removal and installation straightforward.

- 6. Additionally, the absence of valleys and corners prevents puddling and reduces unnecessary liquid flow.

- 7. The round shape of the Tri-Pack produces predictable performance data, which aids in column design.

- 8. The consistent, circular design of each packing element contributes to high mass transfer and heat transfer rates.

Materials and Properties

Tri-Packs can be made from various materials, including polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), and polyvinylidene fluoride (Kynar PVDF or other).

Below are the sizes and corresponding material properties:

Size (inches) | Geometric Surface Area (ft²/ft³) | Packing Factor (1/ft) | Void Space (%) | Weight (lb/ft³) |

|---|---|---|---|---|

| 1" | 85 | 28 | 90 | 6.2 |

| 1-1/4" | 70 | 25 | 92 | 5.6 |

| 2" | 48 | 16 | 93 | 4.2 |

| 3-1/2" | 38 | 12 | 95 | 3.3 |

Tri Packs Design Parameters

- Gas Velocity: 100-500 ft/min. This parameter is influenced by the scrubber's cross-sectional area exposed to gas flow. In counter-current scrubbers, this corresponds to the tower’s cross-section. In cross-flow scrubbers, it relates to the cross-section on a vertical plane of the packed bed.

- Liquid Loading: 2-10 gallons per square foot, based on the cross-sectional area of the scrubber that the liquid flow encounters. In counter-current scrubbers, this area is the tower’s cross-section; in cross-flow scrubbers, it corresponds to the cross-section on a vertical plane of the packed bed.

- Packing Size: For random dump packings, the typical ratio of scrubber diameter to packing size is 12:1.

- pH: For absorption processes involving contaminants that can dissociate in aqueous solutions, the pH level must be specified and controlled.

- Pressure Drop: In new packed beds, the pressure drop should be between 0.02 and 0.2 inches of water per foot of packed bed depth.

- Blowdown and Makeup Rates: These variables should initially be set according to process design and material balance requirements, within the given constraints.

- 1. The shape of the media prevents nesting and settling, achieving an optimal surface-to-open-area ratio.

- 2. Its unique structure allows Tri-Packs to maximize wetting and maintain uniform liquid distribution throughout the bed.

- 3. With no flat surfaces, corners, or pockets, liquid flow remains efficient and uninterrupted.

- Gas absorption, purification;

- Gas & Liquid Separation;

- Liquid extraction;

- Water treatment;

- Biological filtration.

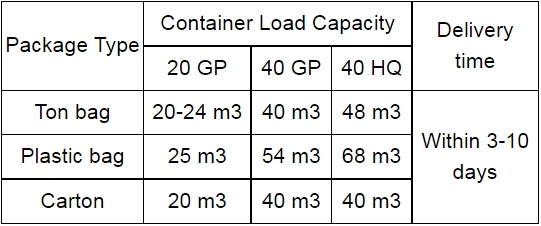

Tri Packs Scrubber Balls Package & Delivery:

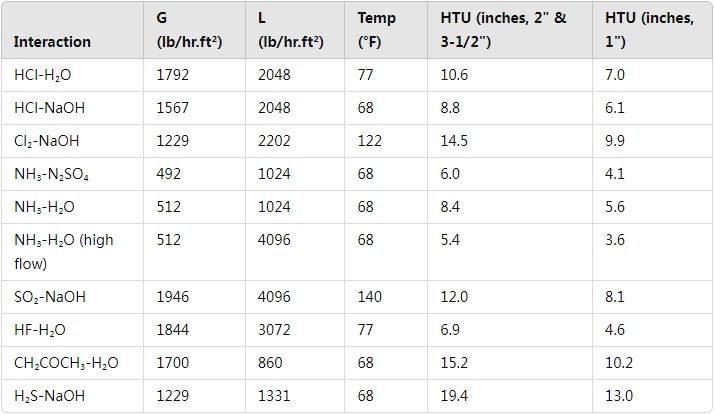

Tri Packs' Mass Transfer Data

Tri-Packs media is designed for efficient mass transfer in various scrubbing applications. The absorption data for different chemical interactions is as follows:

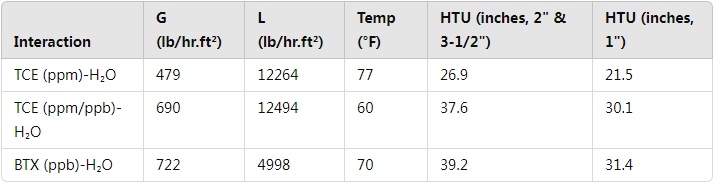

Tri Packs VOC Stripping Data

Tri Packs Performance

Tri-Packs has a distinctive spherical design that has been proven effective in air pollution control systems for decades. This adaptable tower media is also widely used as the industry standard for separation, purification, and degasification systems, as well as for tower aeration in applications such as water and wastewater treatment.

Several features make the Tri-Packs design especially efficient in scrubber applications:

4. Interestingly, surface area alone is not the sole factor influencing performance. Excessive surface area can reduce gas-liquid contact and lead to higher pressure drops, thus increasing energy demands.

5. Tri-Packs has a strong track record of reliability in air pollution control applications, offering users high mass and heat transfer efficiency while effectively helping to keep operational costs low.

6. Tri-Packs tower packing is considered the industry benchmark for random dump tower packing media.

Applications:

- LianChuang has over 20 years of experience in the mass transfer industry. From our headquarters in AnYuan Industrial Zone, PingXiang City, JiangXi Province, China, we provide specialized design and engineering services for clients worldwide. Working with molding facilities both domestically and internationally, we deliver custom orders with a commitment to high quality. We also maintain a large inventory of all kinds of tower packing products, ready for immediate shipment. Welcome contact us to learn more about Tri-Packs or to request a quote.