Trickling filters are an essential biological wastewater treatment device widely used for removing organic matter and ammonia from wastewater. In contrast to the activated sludge process, where microorganisms are suspended in mixed liquor, trickling filters rely on a stationary bed where microorganisms are fixed to the surface. The design and operation of trickling filters focus on using microorganisms’ natural metabolic processes to convert organic pollutants in wastewater into harmless substances like water and carbon dioxide.

What is trickling filter

Trickling filters serve as biological reactors within wastewater treatment facilities designed to eliminate organic matter and/or ammonia from wastewater. In contrast to the activated sludge process, where microorganisms are suspended in a mixed liquor, in trickling filters, these microorganisms are affixed to a stationary bed surface

How trickling filter works

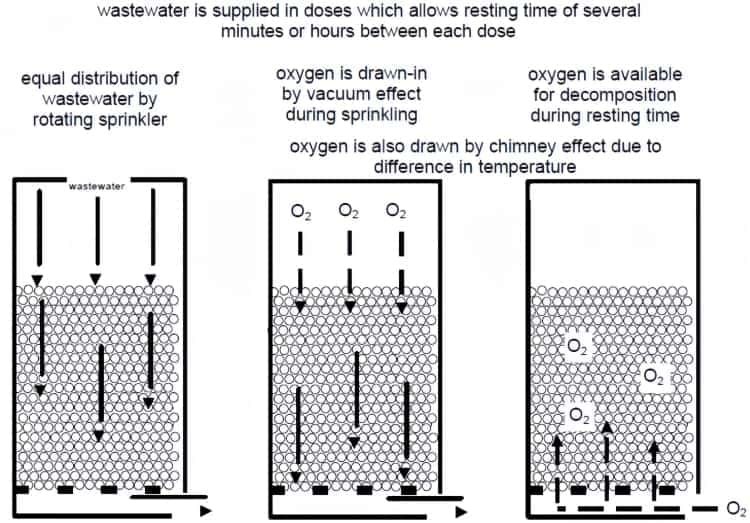

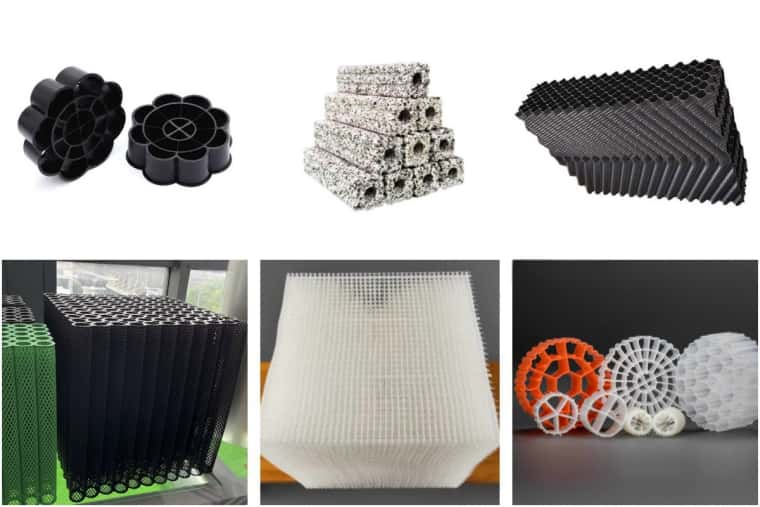

Modern-day trickling filters typically employ structured plastic fill media to provide the fixed bed surface, although historically, rock, gravel, and hardwood were used. Wastewater from primary clarifiers is consistently dispersed over the initial layer of plastic fill media through a rotary distributor. As the wastewater travels downward through the trickling filter, a cross-corrugated pattern within the plastic fill media facilitates effective water-air mixing.

Operating under aerobic conditions, trickling filters typically operate without forced ventilation or aeration. The tower-like structure of these filters prompts air to be drawn into the tower through slots at the filter's base, a phenomenon known as the chimney effect. This effect is caused by the difference in indoor and outdoor air density due to temperature and moisture variations, leading to air buoyancy.

A trickling filter comprises high-specific-surface-area materials, such as shredded PVC bottles, crushed rocks, gravel, or specially designed preformed plastic filter media, to create a biofilm. Microorganisms grow within this biofilm on the media's surface. They adsorb the organic load in the wastewater and stabilize it through aerobic metabolism, converting it into water and carbon dioxide, thus removing oxygen-demanding substances. Wastewater is sprayed onto the media's surface, where it trickles downward, coming into contact with thin layers of microorganisms, further purifying the water.

How to choose trickling filter media

When considering plastic media for trickling filter applications, it's crucial to adopt a forward-thinking approach, aiming for a 20-30 year lifespan. Frequently, the initial cost significantly influences media selection. Opting for cheaper or poorly manufactured media increases the risk of premature failure such as media collapse, delamination, frequent blockages, or sagging, all detrimental to treatment performance and longevity. Essentially, settling for the minimum expectation often leads to minimal performance. A minimum service life of 20 years should be anticipated, but investing more time in the specification and procurement process can yield media lasting 30+ years, resulting in long-term cost savings

Determining the structural integrity and durability of the selected media is essential. We've compiled a checklist of the top five indicators of module strength to consider when specifying media for your trickling filter application:

Material Properties

Detailing plastic properties in the media specification is critical. Tensile strength and flexural modulus are pivotal indicators of a material’s strength. Tensile strength defines a polymer's stress resistance without permanent deformation, while flexural modulus measures a material’s stiffness when force is applied perpendicular to its length.

Gauge

The gauge, or thickness of an individual sheet, typically denotes a stronger module when thicker. However, fluctuations in strength might exist despite meeting specific flexural modulus criteria. While module weight is significant, it should not solely determine strength.

Considering gauge requirements involves examining how that specific gauge has been utilized and the design load it sustains. Gauge measurements differ between pre-forming and post-forming thickness due to plastic stretching during thermoforming. Both measurements should be taken into account, considering the ratio between them.

Tolerances

An accurately aligned pack distributes weight evenly, ensuring structural integrity. Insist that a percentage of modules be checked on-site for face, width, and length tolerance to avoid potential performance inefficiencies or failure.

Compression Testing

Compression testing determines module strength, provided the modules are appropriately designed to withstand the load and creep over time. This method indicates both the strength and lifespan of the media. Plastic behavior varies based on formulations from different suppliers, making compression testing vital to confirm if a media pack meets its designed conditions.

It's crucial to verify that the selected media not only meets the system's design load but also endures the anticipated conditions.

trickling filter media products

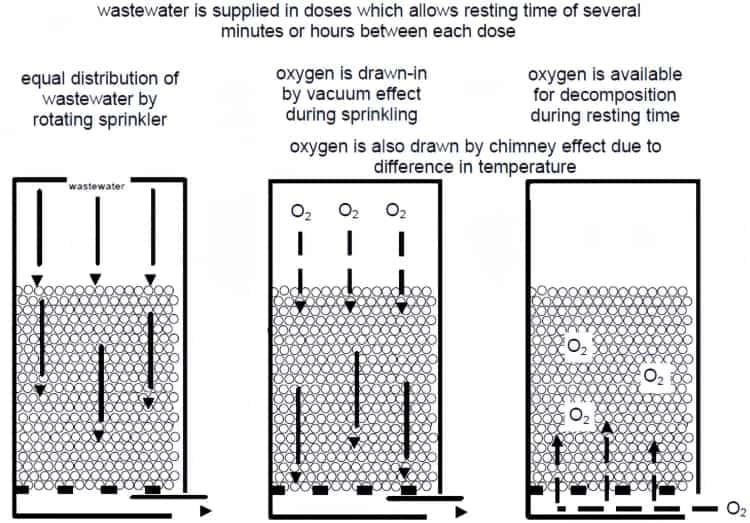

Several types of media are commonly used in trickling filters, each designed to provide a favorable environment for microbial attachment and biofilm formation. These media include:

- Structured Plastic Media:

Specifically designed plastic media with surface structures that maximize surface area for microbial growth. These materials provide an optimal environment for biofilm formation and effective wastewater treatment.

- Shredded PVC Bottles:

Recycled plastic bottles shredded into smaller pieces serve as a cost-effective filler material. These bottles provide a sufficient surface area for biofilm development and are an environmentally friendly alternative.

- Ceramic or Porous Media:

Specialized ceramic or porous materials with intricate designs that encourage microbial attachment. These media are durable and provide a stable environment for biofilm formation, though they tend to be more expensive.

- Pre-formed Plastic Media:

These are custom-engineered plastic media designed to optimize surface area and biofilm growth. They come in unique shapes and textures, enhancing treatment capabilities.

- Composite or Hybrid Media:

Some modern trickling filter media combine different materials such as plastic, ceramic, or other composites to maximize biofilm formation and treatment efficiency.

Advantages of Trickling Filters

Trickling filters offer several key advantages, making them ideal for wastewater treatment in a variety of settings:

- Simple and Reliable: Trickling filters are a well-established technology that is simple to operate and maintain, with a low failure rate.

- Space Efficient: Compared to other traditional treatment methods, trickling filters require less land area, making them suitable for locations with limited space.

- Effective Removal of Organic Matter and Ammonia: Trickling filters are particularly effective at removing biodegradable organic matter and ammonia, making them ideal for treating wastewater with high organic content.

- Resilience to Shock Loads and Toxic Substances: Since trickling filters are non-mixed systems, they are more resilient to shock loads and toxic substances. Toxins only affect localized areas, and recirculation helps to average out the impact of shock loads.

- Low Energy Consumption: Trickling filters typically do not require mechanical equipment such as blowers, resulting in lower energy consumption.

- Low Maintenance: With fewer moving parts and simple operation, trickling filters require minimal maintenance compared to other complex systems.

- Suitable for Small to Medium Communities: Due to their low energy requirements and ease of operation, trickling filters are particularly well-suited for small to medium-sized communities or municipalities.

- Efficient Sludge Management: The sludge produced in trickling filters is easily dewatered, as it primarily comes from the sloughed-off biofilm. This sludge settles and dries better than activated sludge.

Conclusion

Trickling filters provide an efficient and cost-effective solution for wastewater treatment, especially in small to medium-sized communities. With their ability to remove organic matter and ammonia, low energy consumption, and simple maintenance, trickling filters are a reliable and sustainable choice for long-term operation. Careful selection of high-quality media is crucial for optimizing performance and ensuring the longevity of the system. When implemented properly, trickling filters can offer significant environmental benefits while minimizing operational costs