Product Description

Molecular sieve is a specialized aluminosilicate compound structured in a cubic lattice. It consists of aluminosilicate linked by oxygen bridges to form an open skeletal framework, which features uniform pore channels and well-organized cavities. These cavities have a significant inner surface area and are connected by micro-pores that allow for selective absorption. The sieve contains metal ions of larger radii and low electrical charge, along with water molecules that can be removed through heating. As the water evaporates, the crystal structure remains intact, leaving behind cavities of consistent size, which are interconnected by micro-pores. These micro-pores facilitate the selective absorption of smaller molecules, while larger molecules are excluded. This characteristic allows for the separation of molecules based on size, shape, polarity, boiling point, and saturation.

3A Molecular Sieve is an alkali metal aluminosilicate; it is the potassium form of the type A crystal structure.Type 3A has an effective pore opening of about 3 angstroms (0.3nm). This is large enough to allow in moisture, but excludes molecules such as unsaturated hydrocarbons which can potentially form polymers; and this maximizes lifetime when dehydrating such molecules.

Key Properties of 3A molecular sieve:

Non-corrosive

Rapid adsorption

Low moisture retention

Minimal nitrogen absorption

Low electrostatic buildup

Low dust production

Uniform granulation

High compressive strength

Enhanced adsorption performance

High Delta T value

Effective in controlling moisture

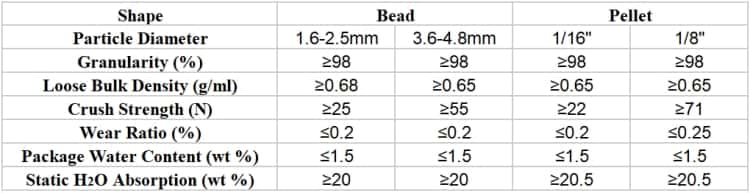

Specification:

Application:

1. Separation of enriched oxygen from air.

2. Production of medical or bulk oxygen in PSA units.

3. Removal of co2 and moisture from air (air pre-purification)and other gases.

4. Catalyst protection , removal of oxygenates from hydrocarbons(olefin streams)

5. Removal of mercaptans and hydrogen sulphide from hydrocarbon liquid streams such as LPG, butane, propane etc.