Product Description

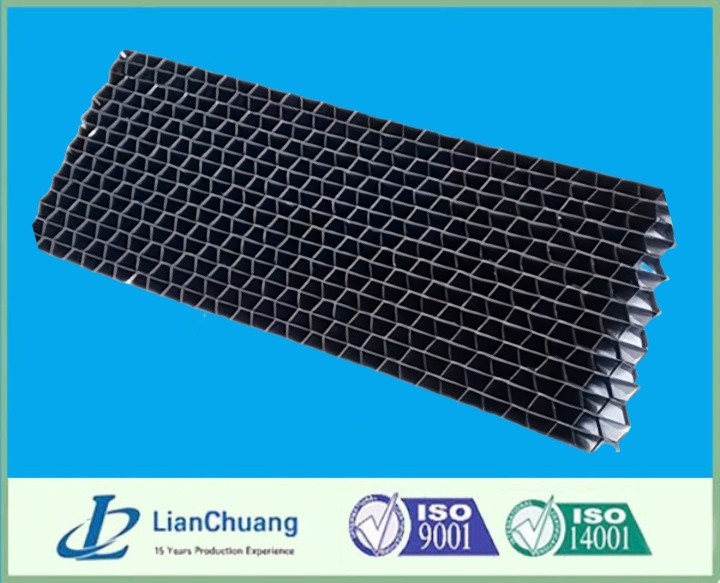

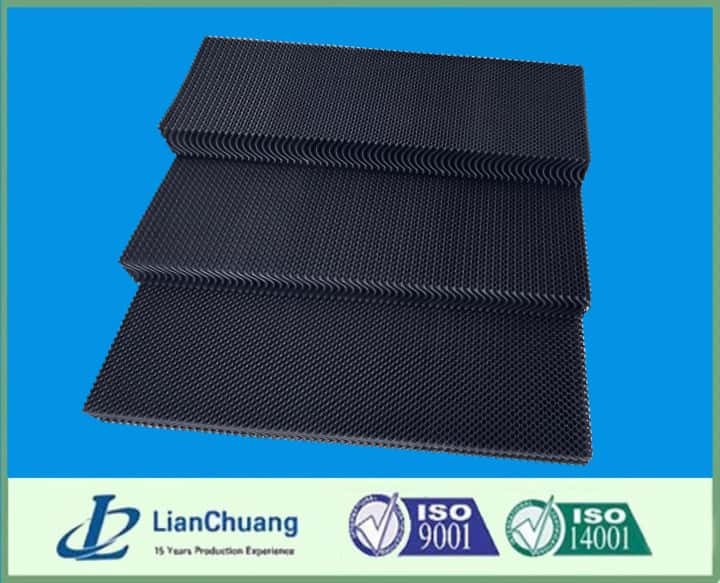

Cooling Tower Air Inlet Louver is an essential component of a cooling tower system, playing a crucial role in ensuring efficient operation, extending equipment lifespan, and maintaining water quality. As part of the cooling tower's air intake, the primary function of the air inlet louver is to regulate airflow while acting as a barrier to sunlight, noise, debris, and water splash, ensuring the cooling tower operates at its optimal performance.

In a cooling tower, water and air combine in a way that may lead to undesirable conditions, such as algae growth, water and chemical quality degradation, or water splashing out of the tower. The design of the air inlet louver addresses these issues by preventing external interference and optimizing airflow, helping maintain the water quality and quantity inside the cooling tower.

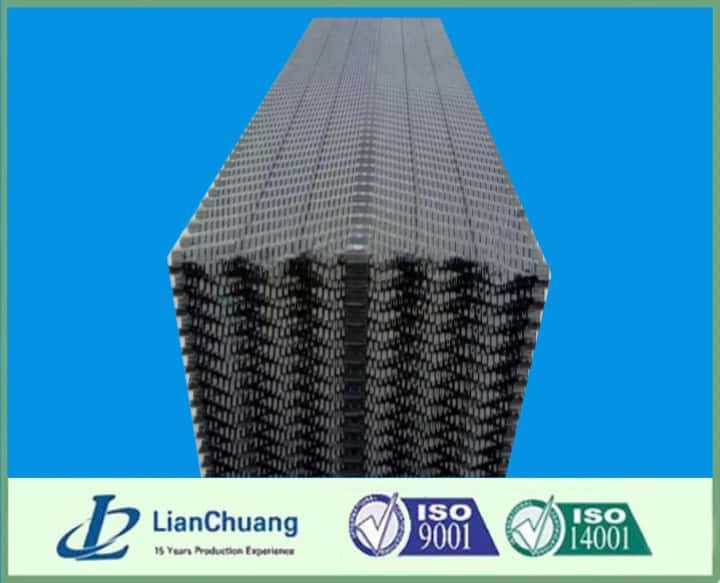

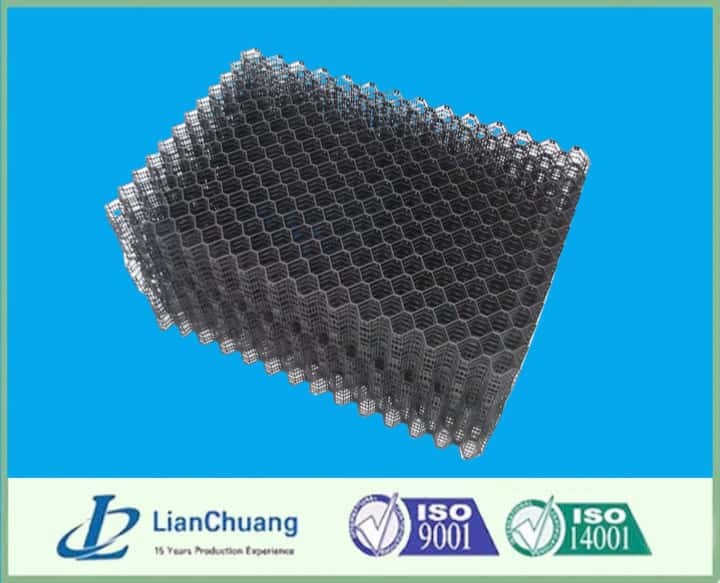

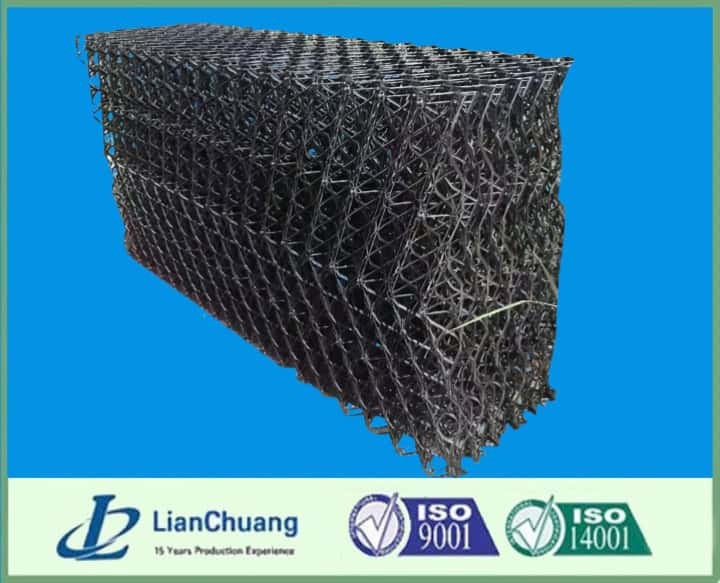

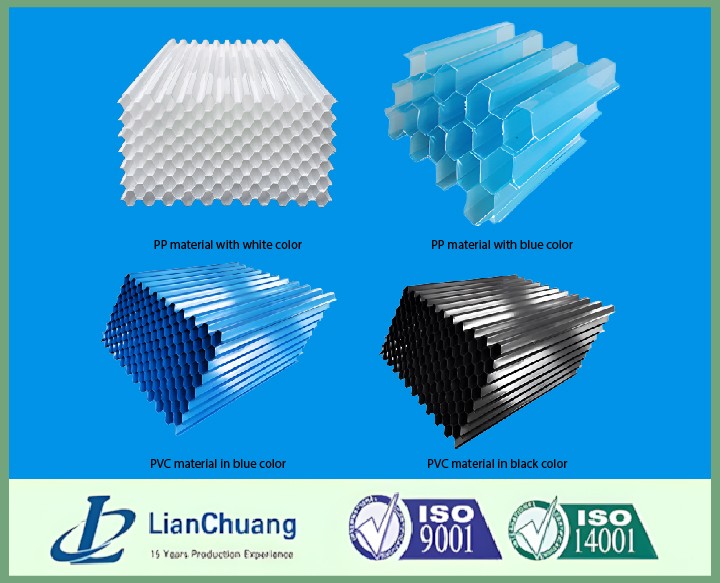

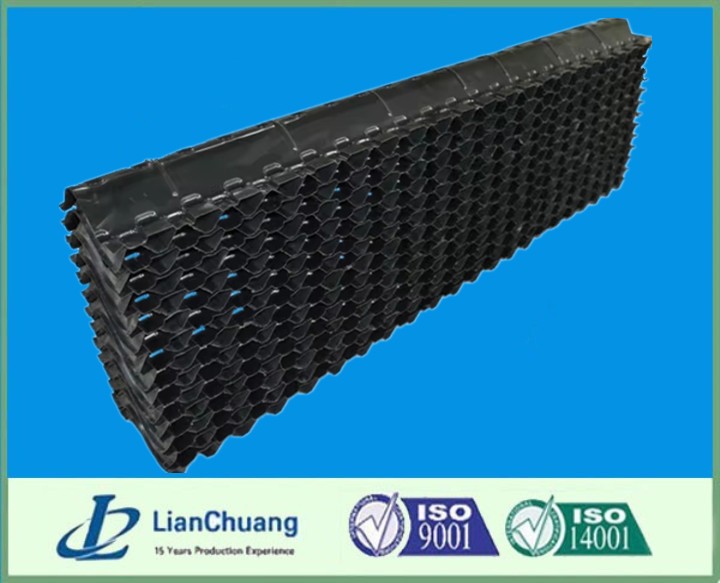

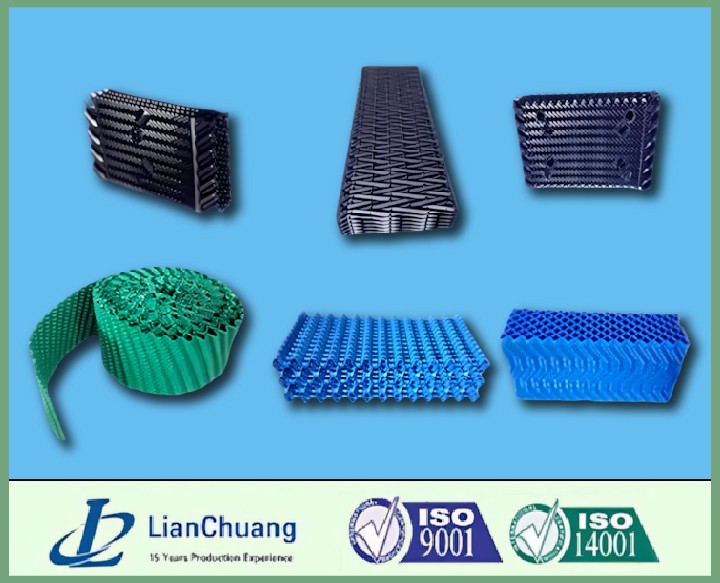

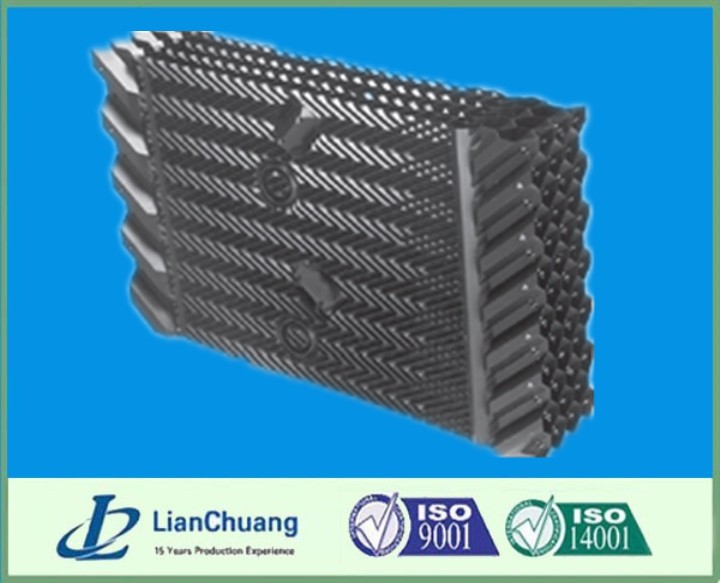

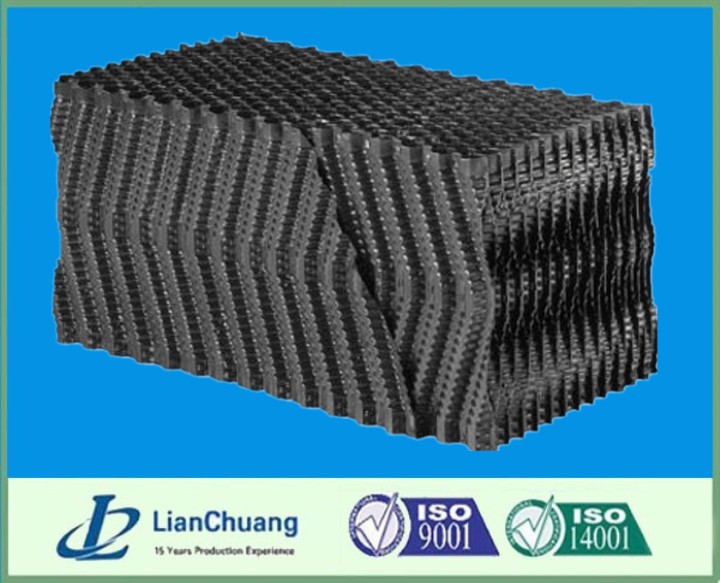

Materials and Design

The materials and design of air inlet louvers vary widely. Common materials include polyvinyl chloride (PVC), galvanized steel, and stainless steel, all of which are corrosion-resistant, UV-resistant, and offer long service lives. Depending on the specific needs of the cooling tower, air inlet louvers can be customized in terms of size and design to better suit different structures and environmental conditions.

- Size and Specifications: The width, thickness, and length of air inlet louvers vary depending on the model, design, and manufacturer. Common sizes range from 700 to 800 millimeters in width, with lengths up to 2400 millimeters. Some manufacturers also offer customized sizes to meet specific installation needs.

- Smooth Surface Design: Air inlet louvers typically have smooth, glossy surfaces, which help reduce the buildup of scale, making cleaning and maintenance easier.

- UV and Corrosion Resistance: Many air inlet louvers are UV-resistant and corrosion-resistant, which not only extends the lifespan of the louvers but also ensures their long-term performance.

Advantages of Air Inlet Louvers

For both packaged and field-assembled counterflow cooling towers:

Enhance airflow into the cooling tower

Prevent debris from entering

Eliminate water splash-out

Block sunlight from entering the cooling tower

Reduce noise levels from the tower

Enhance the overall aesthetic of the cooling tower

Applications

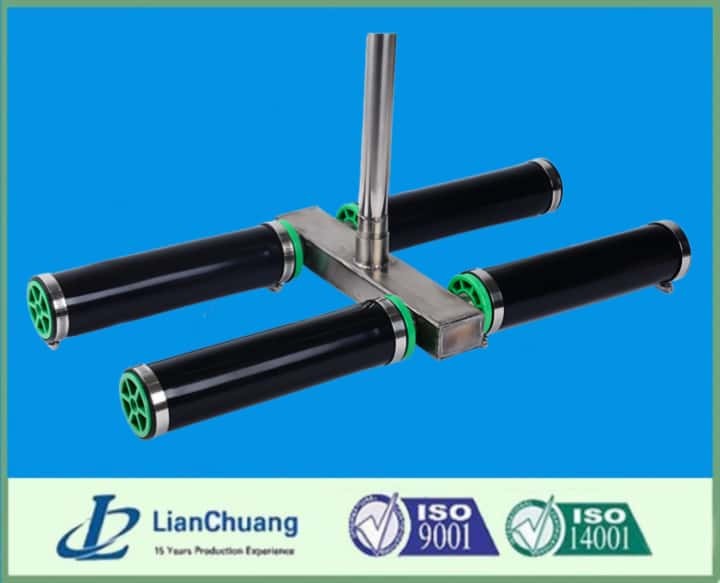

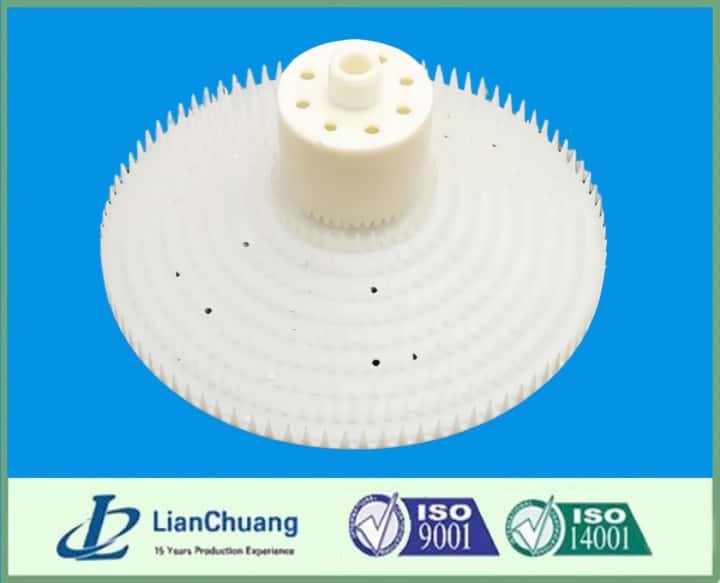

Air inlet louvers are widely used in various types of cooling towers, particularly in large industrial facilities, factories, refineries, and any projects requiring heat exchange or cooling systems. They are designed to fit different brands and models of cooling towers and can be custom installed to ensure stable system operation.

In addition, air inlet louvers are suitable not only for new cooling towers but also for retrofitting existing ones, effectively extending the cooling tower’s lifespan and improving its operational efficiency.

Summary

Although the air inlet louver may seem like a small component in the overall cooling tower system, it plays an indispensable role in ensuring the efficient operation and longevity of the cooling tower. By blocking sunlight, reducing water splash-out, preventing debris infiltration, and optimizing airflow, the air inlet louver significantly improves cooling tower performance and water quality management.

Choosing the right air inlet louver and installing it professionally is crucial for ensuring the long-term, stable operation of the cooling tower while reducing maintenance costs. Therefore, regular inspections and timely updates or replacements of the air inlet louvers are essential for maintaining the cooling tower’s high efficiency, environmental sustainability, and cost-effectiveness.

Our air inlet louvers are made from UV-stabilized PVC, offering rigid durability and a variety of lengths to meet specific installation needs. These louvers can rejuvenate an old cooling tower, making it work like new, and are an excellent replacement for worn-out fiberglass or galvanized steel louvers.

Using new materials makes regular maintenance easier and more time-efficient. Rigid PVC mounting brackets and assembly frames ensure easy installation and cleaning access. Additionally, these louvers may offer the added benefit of improved noise control, further enhancing the overall performance of the cooling tower.