Product Description

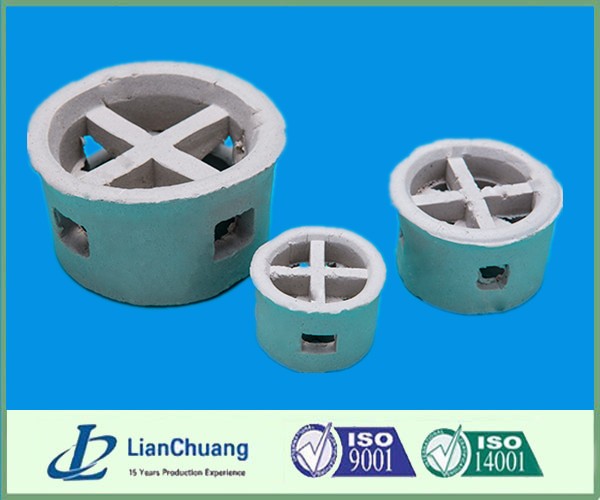

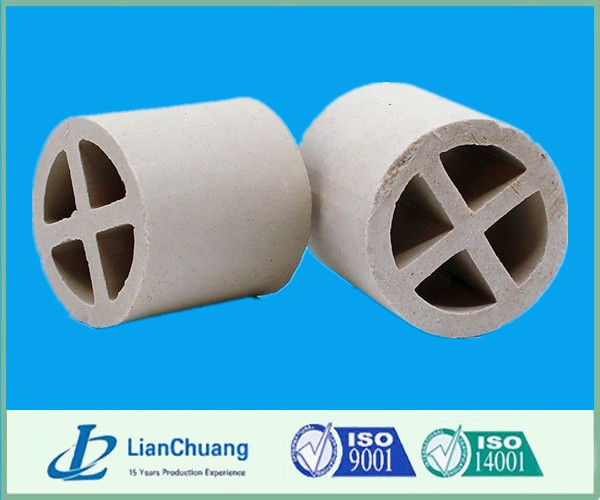

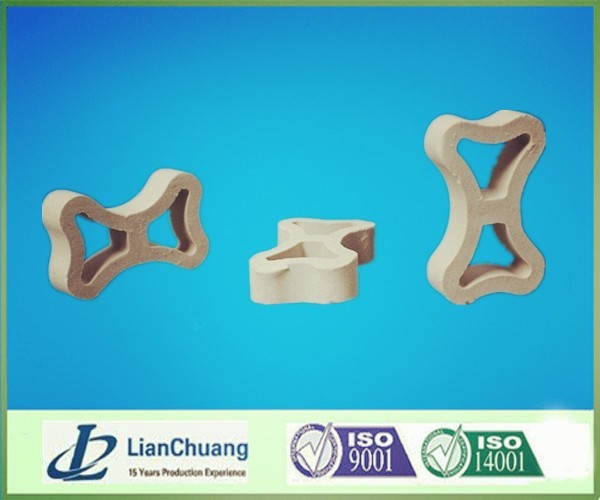

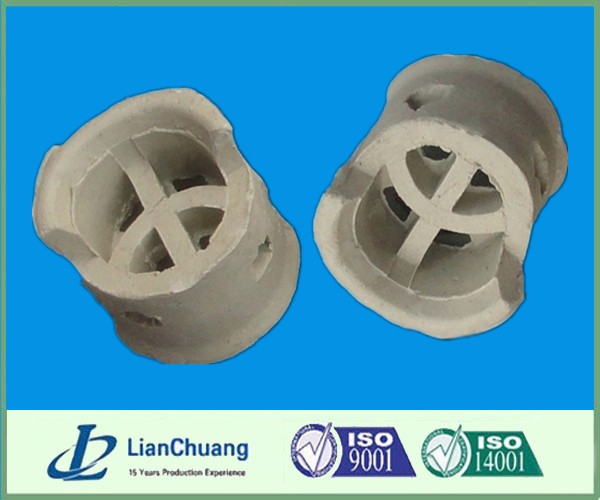

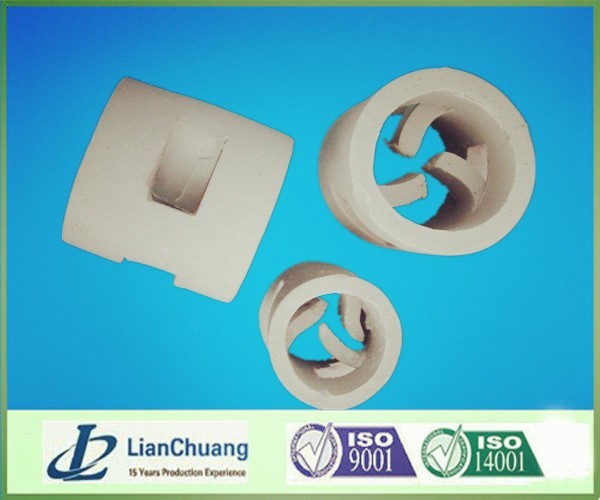

ceramic cascade ring has an aspect ratio of only 1: 3 or 1:2 etc. Its height is typically only 1/3 or 1/2 of its diameter. The unique structural design makes the packing mainly point contact when stacked, which not only increases the porosity of the packing, reduces the airflow resistance, but also greatly improves the gas-liquid distribution performance in the packing layer. The center of the cascade ring has two layers of cross shaped fins, with the upper and lower fins staggered at a 45 degree angle, suitable for carbon dioxide degassing towers and synthesis tower packing.This minor change in geometry has made a profound effect on the process performance of the packing. When the ceramic cascade ring dumped in a tower, the flat cascade rings formation tends to make themselves preferentially in a near horizontal position. with their cylindrical axis predominantly in the direction of the vapor and liquid flow. This is exactly the opposite of the tendency of pall ring and other same high aspect ratio ceramic rodom tower packing.

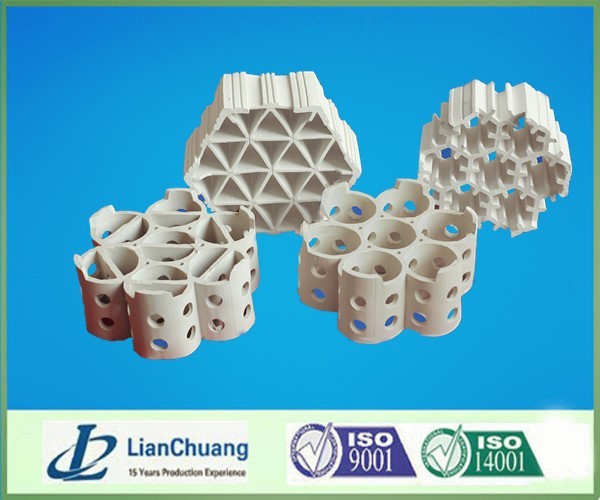

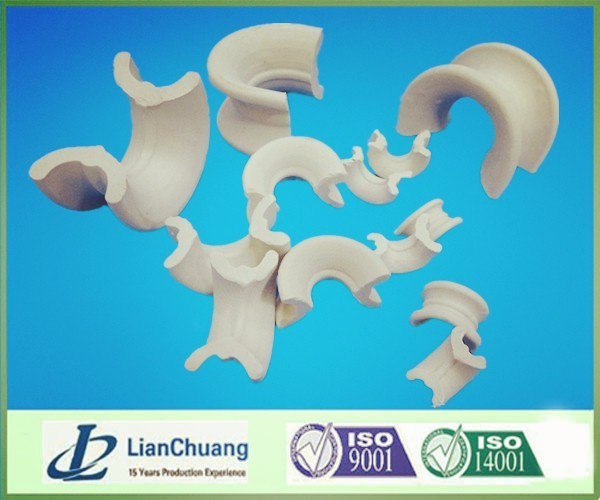

Ceramic cascade rings can be widely used in various packing towers of desiccation, absorption, cooling, washing, and regeneration in industries of petrochemical, chemical, metallurgy, gas and oxygen generation.

Features:

1. The stepped structure increases the surface area and void fraction, enhancing mass transfer efficiency and reducing pressure drop.

2. Resistant to acids and alkalis, capable of withstanding high temperatures, and ideal for handling corrosive gases or liquids.

3. Delivers high efficiency while minimizing energy consumption, making it a sustainable choice for industrial applications.

4. Suitable for a wide range of operations including distillation, absorption, and drying, and compatible with various reactor towers and equipment.

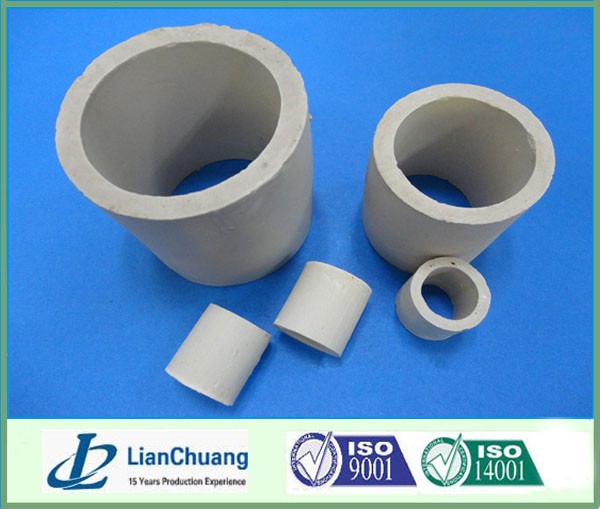

Specifications of Ceramic Cascade Ring:

Normal | D*H*T | Surface area | Void space | Bulk density | No.elements | Packing factor |

mm | mm | m2/m3 | % | kg/m3 | per/m3 | m-1 |

25 | 25*15*3 | 210 | 73 | 650 | 72000 | 540 |

38 | 38*23*4 | 153 | 74 | 630 | 21600 | 378 |

50 | 50*30*5 | 102 | 76 | 580 | 9100 | 232 |

76 | 76*46*9 | 75 | 78 | 530 | 2500 | 158 |

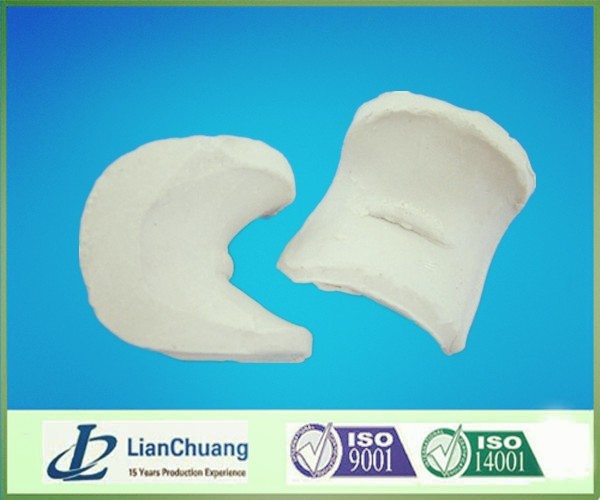

Ceramic cascade ring Chemical Composition

SiO2 | Al2O3 | SiO2+Al2O3 | Fe2O3 | CaO | MgO | K2O+Na2O | Other |

>69% | 15-23% | >92% | <1%> | <0.25 | <0.2% | 2-4% | <1% |