Product Description

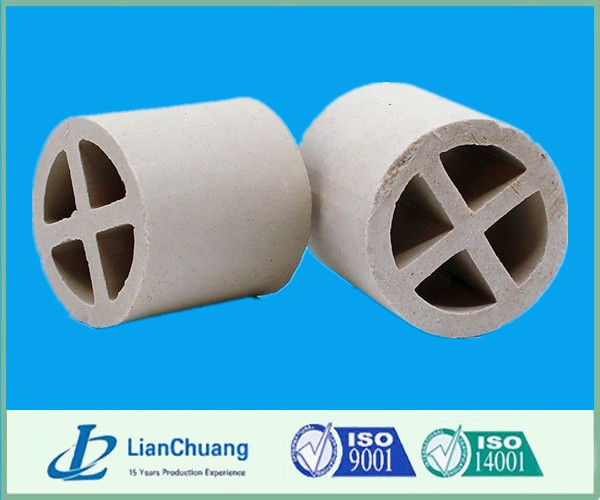

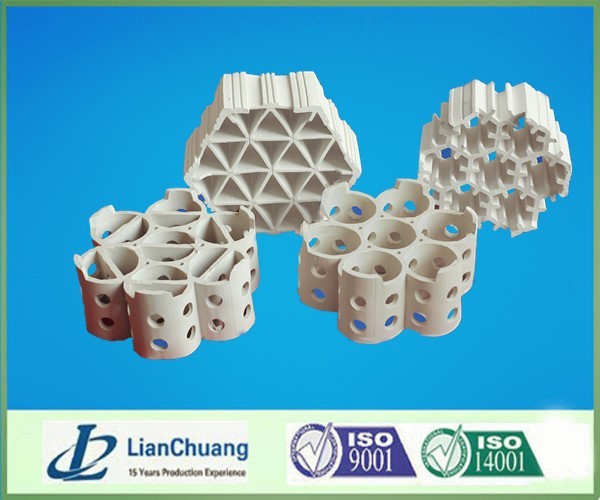

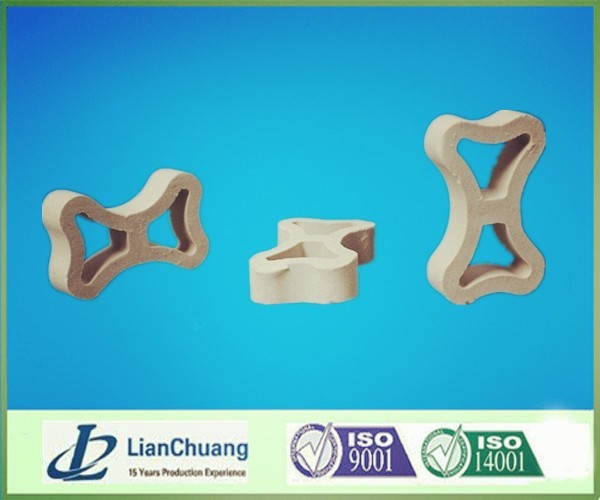

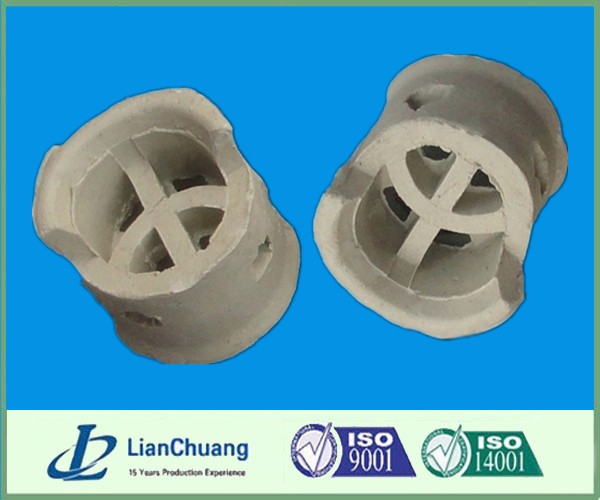

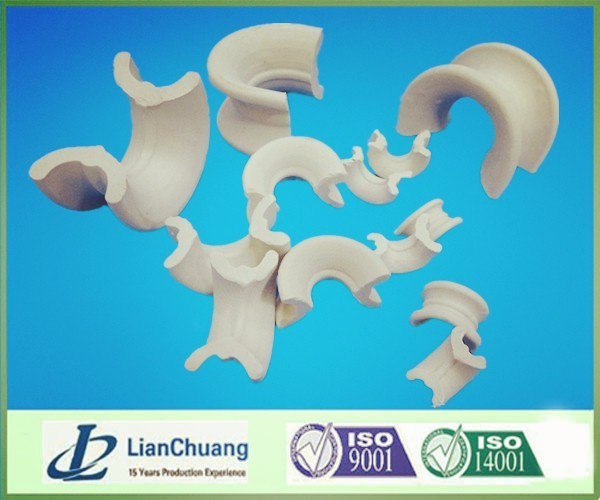

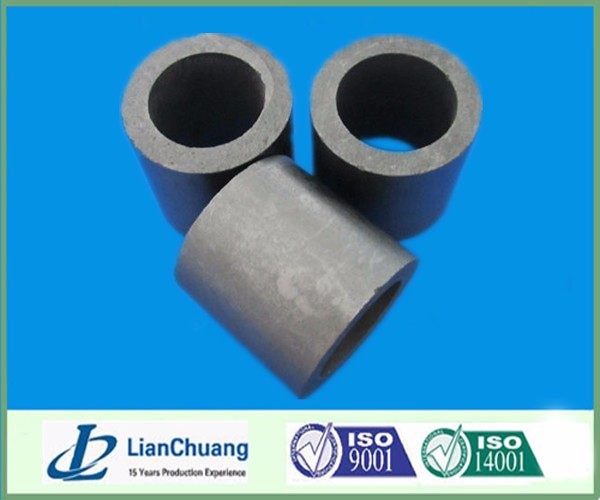

The Ceramic Gear Ring, also known as Ceramic Corrugated Raschig Ring, is an innovative and high-performance packing material specifically designed for chemical engineering applications. Its symmetrical gear-shaped structure, uniform surface distribution, and open apertures enhance the efficiency of gas-liquid contact, making it an ideal choice for applications requiring superior mass transfer efficiency and minimal pressure drop.

Key Features

- Larger Specific Surface Area: Offers over 30% more surface area compared to similar products, enhancing mass transfer capabilities.

- Low Gas Resistance: Open-structured design reduces pressure drop by approximately 30%, ensuring smooth gas flow.

- High Flow Rate: Allows up to a 28% increase in gas throughput for high-capacity operations.

- Symmetrical Design: Geometrically balanced and uniformly distributed structure for consistent performance and durability.

- Thermal Stability: Withstands rapid heating and cooling cycles for processes with extreme thermal variations.

Applications

The Ceramic Gear Ring Packing is ideal for use in various chemical processing and environmental applications, including:

- Distillation: Enhancing separation efficiency in packed columns.

- Stripping: Effective removal of unwanted components in gas or liquid streams.

- Absorption: Maximizing gas absorption efficiency in chemical towers.

- Extraction: Supporting high-efficiency liquid-liquid extraction processes.

- Dehydration: Removing moisture efficiently in drying towers.

- Desulfurization and Decarbonization: Enhancing gas treatment processes for environmental compliance.

Advantages

- Increased operational efficiency due to high surface area and open aperture design.

- Reduced energy consumption from lower pressure drop.

- Improved gas and liquid distribution for enhanced mass transfer performance.

- High durability and adaptability for diverse operating conditions and chemical processes.

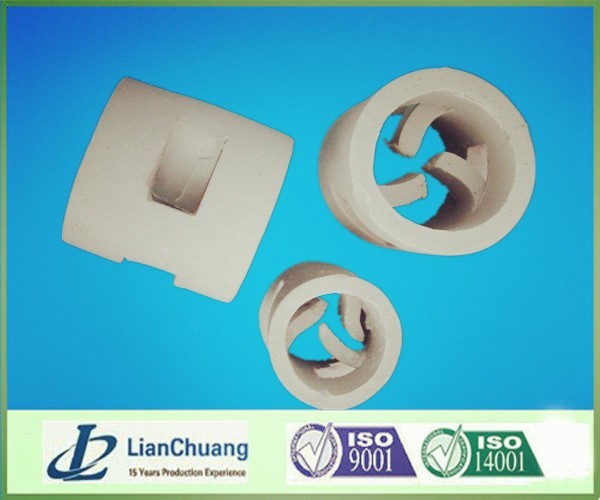

Versatility in Production: The Ceramic Gear Ring Packing is available in various sizes and specifications to meet the specific needs of experimental packed columns, industrial-scale towers, and other specialized equipment.

Choose the Ceramic Gear Ring Packing for superior efficiency, cost-effectiveness, and long-lasting performance in your chemical processing needs.