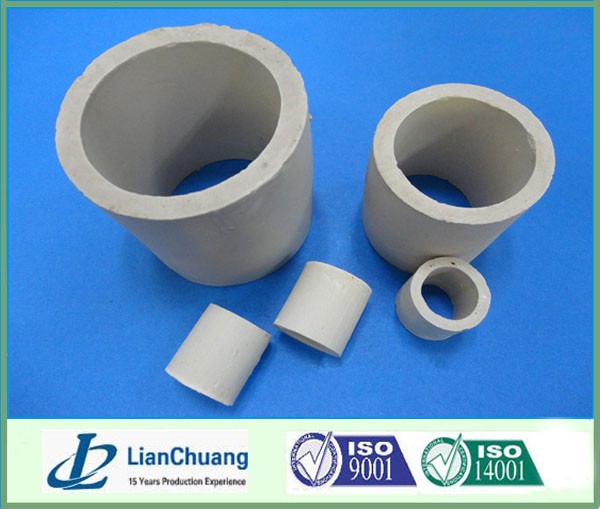

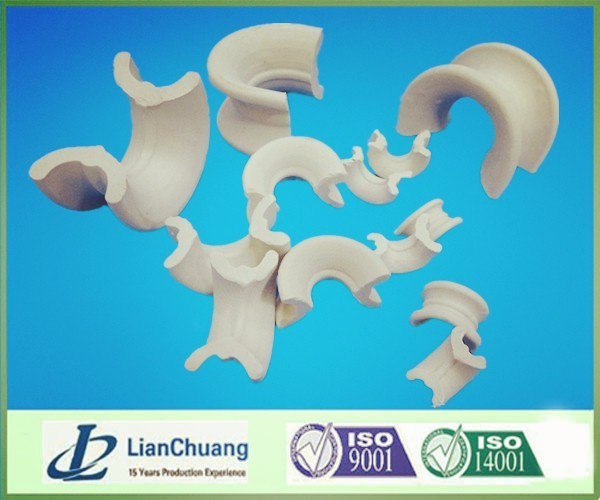

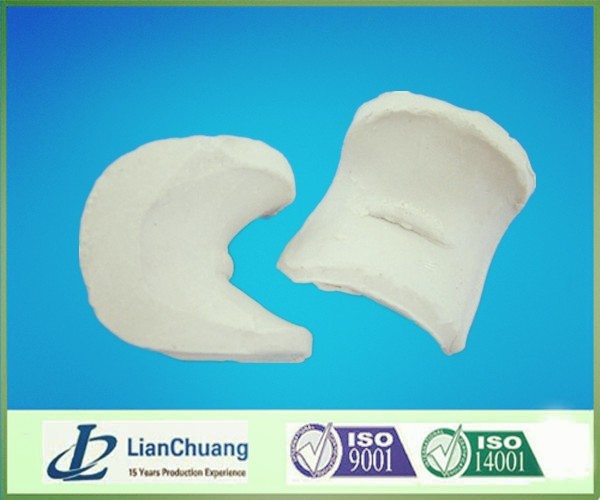

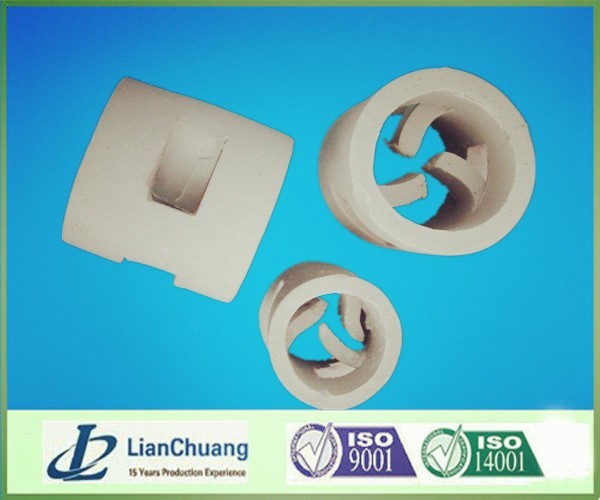

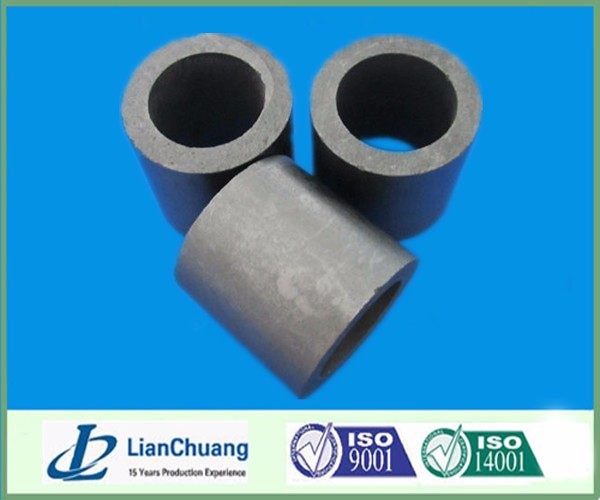

Product Description

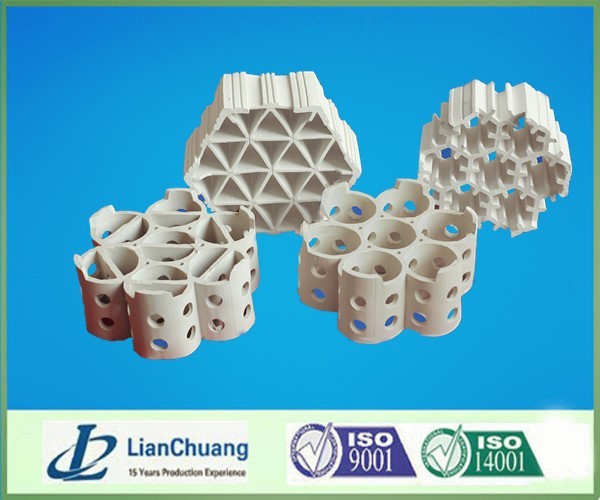

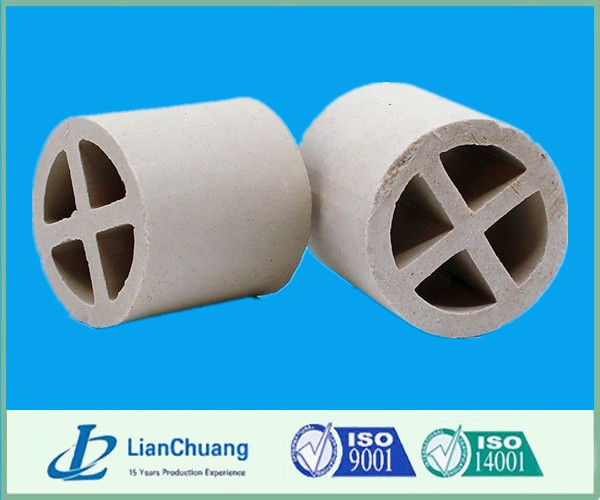

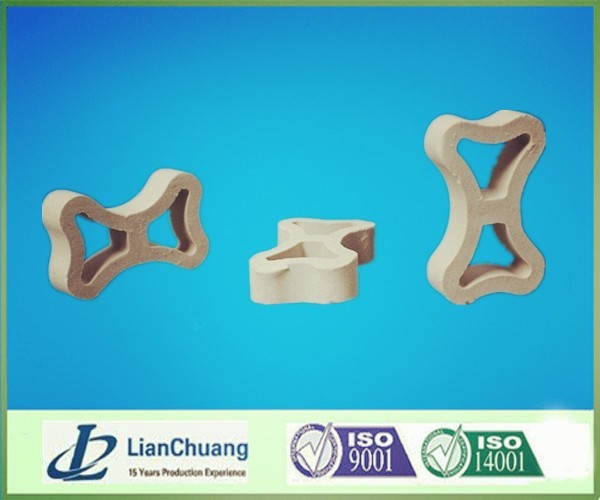

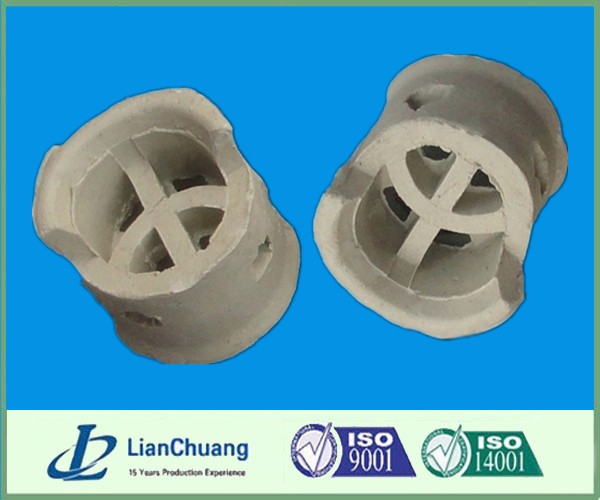

Ceramic connecting combination ring packing has get rid of the shortcoming of the old-style packings that is large in resistance. short in service life, easy to be corroded and broken.Ceramic structured combination tower packing is made up of multiple packing units with a similar geometric design. Thanks to its unique ceramic structure and excellent hydrophilic properties, it forms a thin liquid film on the surface, which is conducive to turbulent airflow. The design incorporates tilted and tortuous channels that enhance air flow without obstructing it, offering a significant advantage over metal packing.

Additionally, ceramic packing boasts superior corrosion resistance and high-temperature endurance, outperforming metal alternatives. Its surface structure ensures excellent wettability, accelerating liquid flow and minimizing fluid volume retention, which helps reduce overheating, aggregation, and coking risks.They are reformed packings with the advantage of simple structure,high operation, good flexibility,efficient mass transfer and excellent press drop.After the glazing surface of the ceramic connecting rings are cleaned They can be used again.

Characters:

1. Light specific gravity and low obstruction

2.A large mass-transfer co-efficient, large valid area and excellent effectiveness

3.Resist aging, sudden heat and sudden coldness

4.New structure that can make circular shapes, is able to be cut and easy to pack

Specifications:

Application:

They are widely applied to washing tower for coal gas in generation furnace,benzene,naphthalene and ammonia washing tower for coking gas,desulphurization tower,decarbonising tower,carbon dioxide removal tower,oil refining and chemical project. They are especially applicable to extraction and fractionation.