Product Description

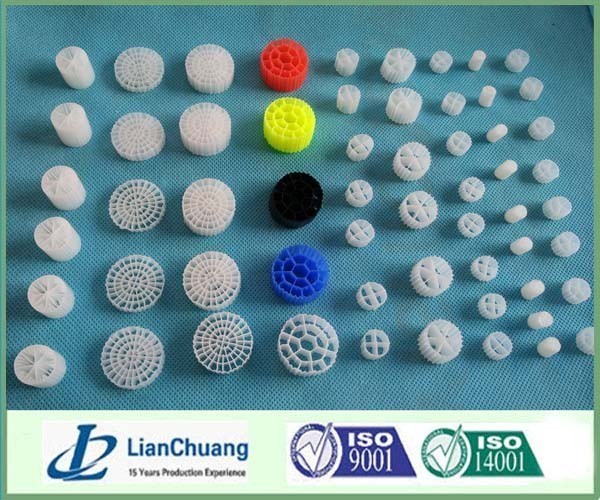

Bubble diffusers are used to introduce air into sewage systems or industrial wastewater treatment. Microorganisms in the water require oxygen to break down contaminants, and bubble diffusers are designed to support this biological process by maximizing oxygen transfer. This series combines innovative design, cost-effective installation, dependable performance, and high efficiency in both continuous and intermittent aeration systems. They are specifically engineered to deliver optimal oxygen transfer rates and to withstand long-term operational demands.

Membrane Materials and Specialization

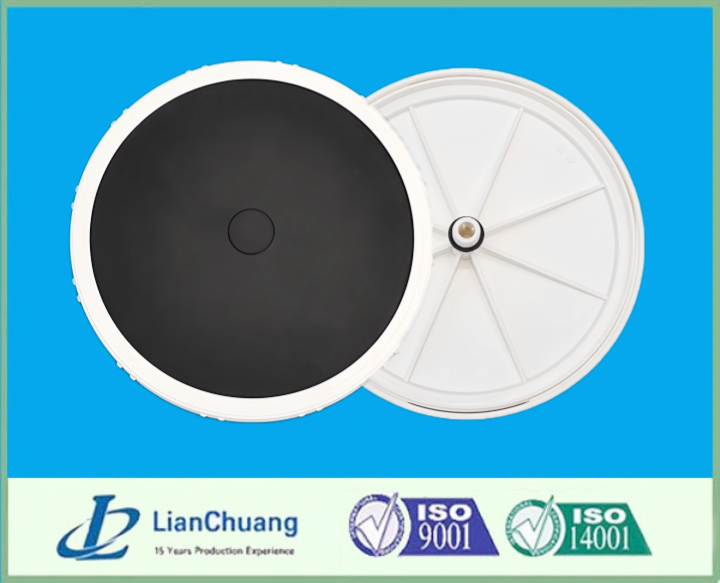

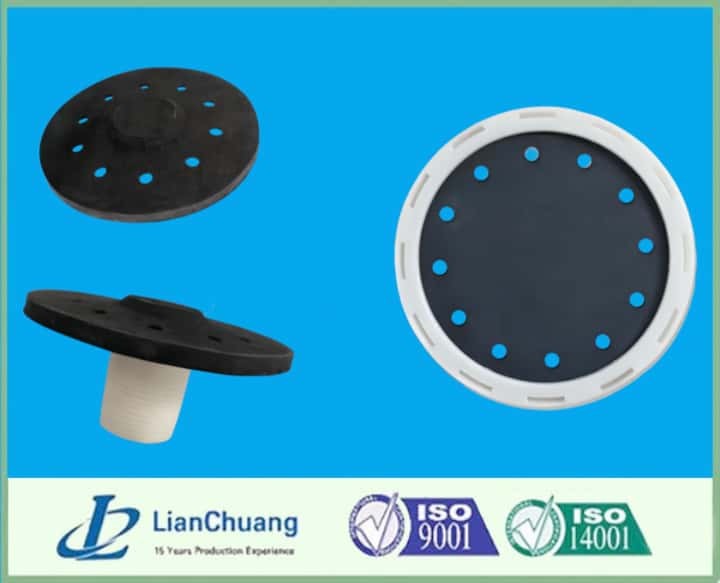

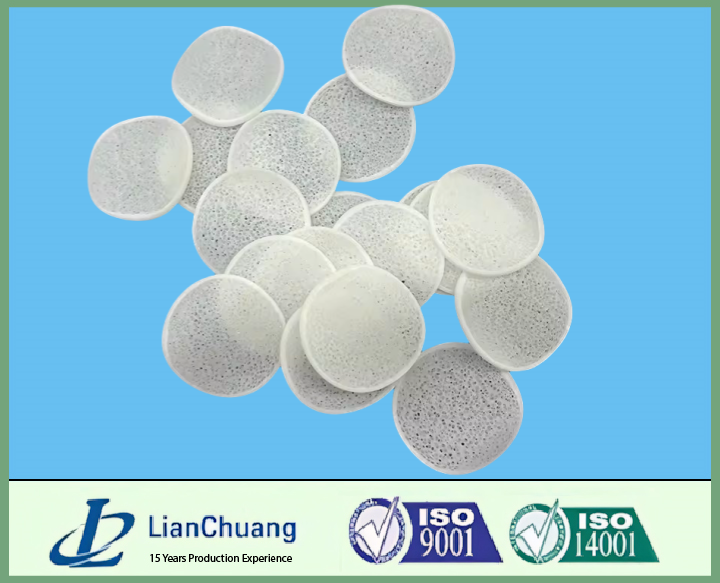

Our fine bubble diffusers come with various membrane options tailored to different industries. We offer disc diffusers equipped with low plasticizer EPDM membranes, ideal for use in food and beverage production, as well as in animal processing. For industries such as petrochemicals, paper manufacturing, and refining, we provide diffusers with silicone membranes, designed to withstand the unique challenges of these environments.

Anti-Fouling Membrane Technology

Leveraging the latest advances in nanotechnology, our membrane surfaces are engineered to resist the accumulation of biological growth and solid encrustations. This self-cleaning feature enhances the longevity and performance of the diffuser, reducing the need for maintenance and ensuring efficient operation over time.

Reinforced Structural Components

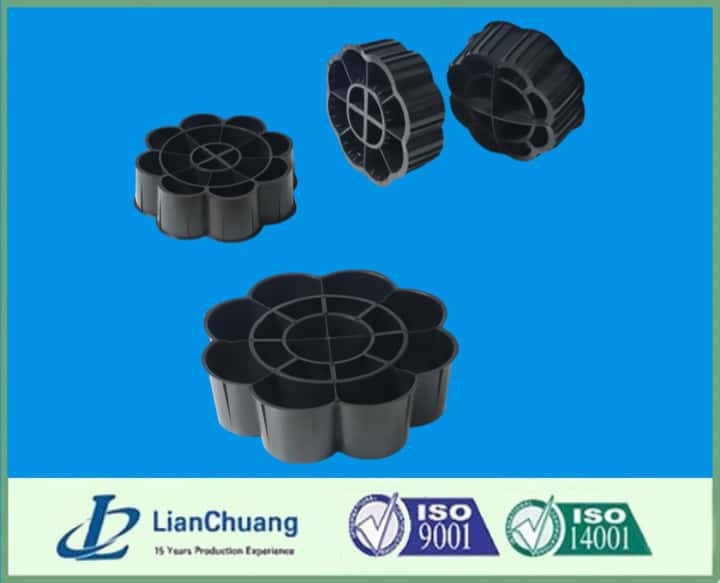

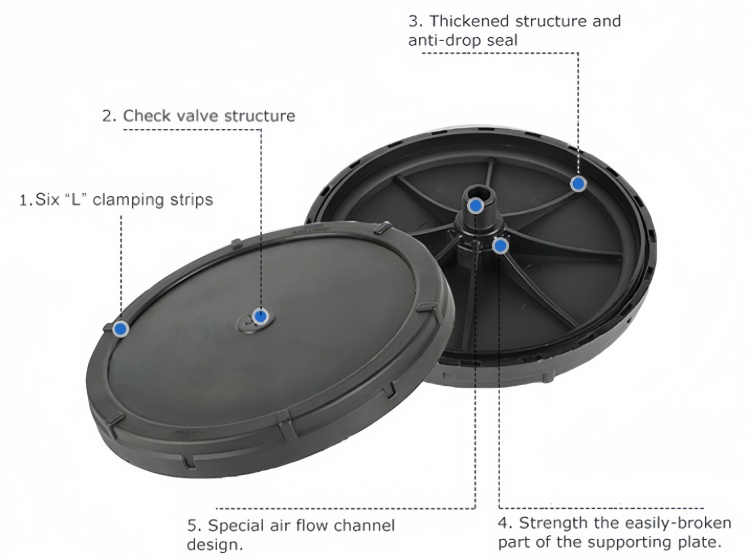

The diffuser discs are supported by reinforced polypropylene rings and support dishes, which are fortified with glass fiber for superior chemical resistance. These robust materials offer protection against high temperatures and UV exposure. All our diffusers also include built-in non-return valves, which prevent backflow, block sludge buildup, and maintain optimal operation, especially in systems with fluctuating airflow.

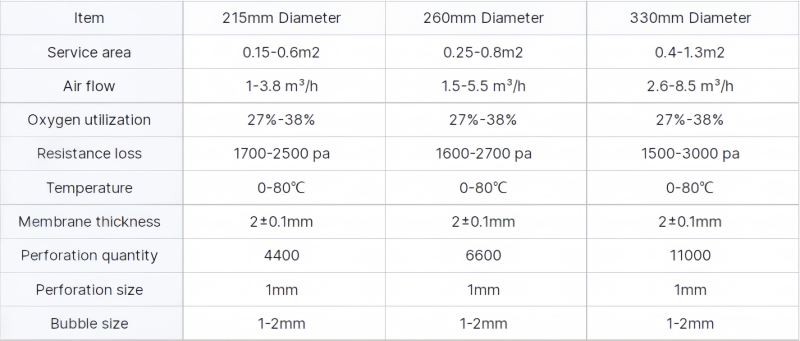

Speicification of Fine Bubble Diffusers

Key Features of FineBubble Diffusers

- 1. High Oxygen Transfer Efficiency: Maximizes oxygen dissolution into the water for efficient biological treatment.

- 2. Superior Resistance to Clogging and Corrosion: Ensures durability and low maintenance needs.

- 3. Wide Flow Range: Accommodates various aeration requirements across different applications.

- 4. Low Pressure Drop: Reduces energy consumption and operational costs.

- 5. Energy-Efficient: Minimizes operational costs while maintaining performance.

- 6. Simple Installation: Easy to integrate into existing systems.

- 7. Prevents Backflow: Ensures safety and system stability.

- 8. Self-Cleaning Mechanism: Maintains continuous performance with minimal upkeep.

- 9. Intermittent Operation Compatibility: Suitable for processes with variable air flow.

- 10. Slide-Off Prevention: Disc design prevents slippage under dynamic conditions.

Applications

- 1. Recirculating Aquaculture Systems (RAS): Used for water treatment in fish farming and shrimp ponds.

- 2. Sewage Treatment for the Pulp and Paper Industry: Efficiently treats wastewater from paper production processes.

- 3. Food and Beverage Wastewater Treatment: Applied in secondary treatment systems for wastewater from the food and beverage industry.

- 4. Coke and Steel Plants: Utilized for aeration in industrial wastewater treatment at coke and steel manufacturing facilities.

- 5. Municipal Sewage Treatment Plants: Standard in urban wastewater treatment processes for secondary purification.

- 6. Dyeing Industry Wastewater Treatment: Designed for effective treatment of textile dyeing effluents.

- 7. Chemical and Dairy Industries: Ideal for handling wastewater from chemical processes and dairy production facilities.

- 8. Wastewater Disposal in Various Industries: Suitable for chemical wastewater management and treatment across multiple sectors.

- 9. Integrated A²O Systems: Can be used in advanced integrated biological nutrient removal systems.

In conclusion, bubble diffusers are a crucial technology for optimizing oxygen transfer in a wide range of wastewater treatment applications, helping to ensure the efficient and sustainable treatment of industrial and municipal wastewater.