Product Description

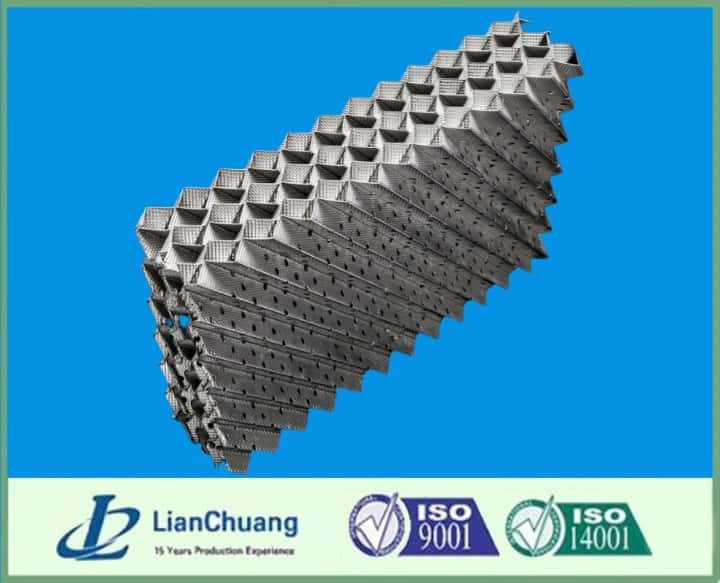

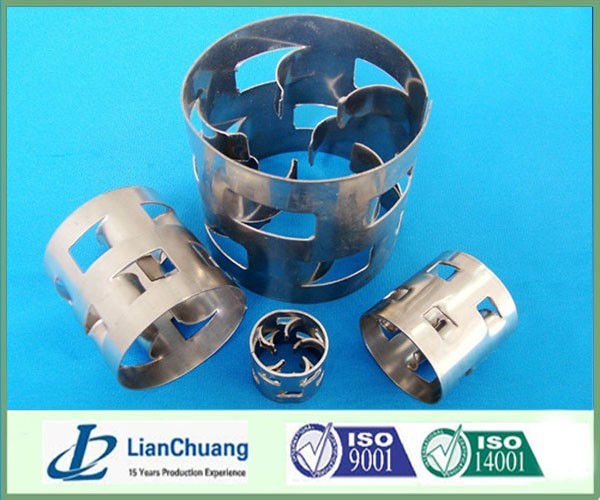

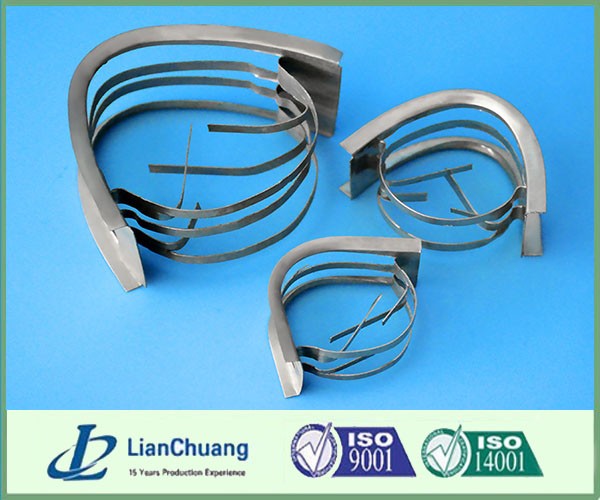

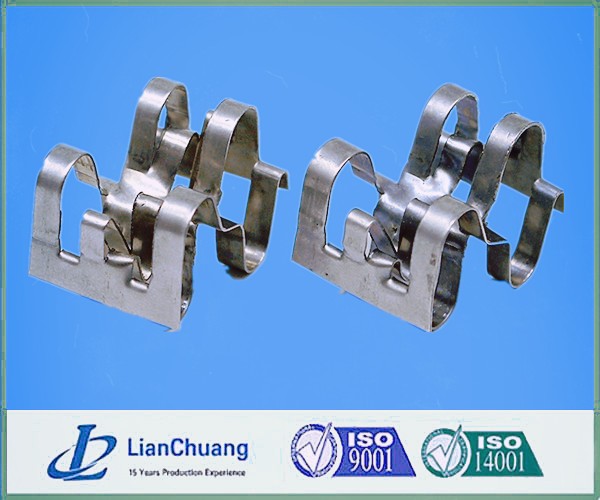

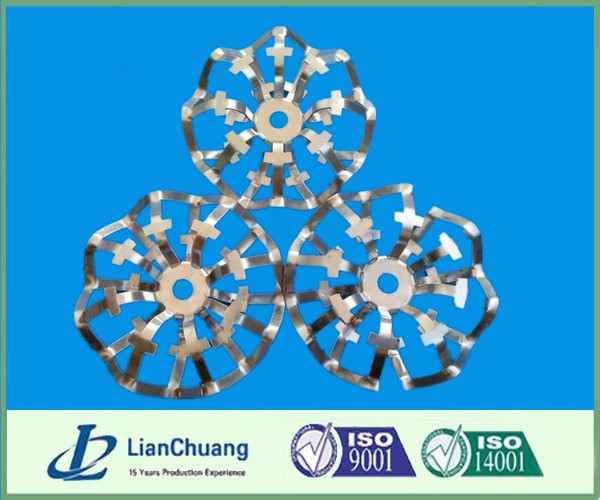

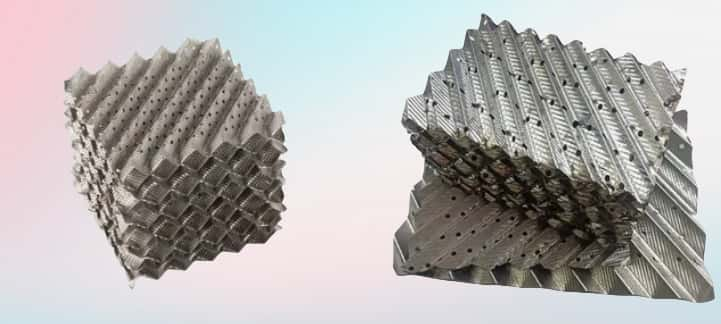

The Distillation Structured Flexipac Packing is a high-efficiency, flexible packing designed for advanced separation processes, particularly in distillation applications.

Structured Flexipac Packing comes in various corrugation crimp sizes, with two distinct inclination angles for each type:

"Y" Designated Packings

- 45-degree nominal inclination angle from horizontal;

- The most commonly used type.

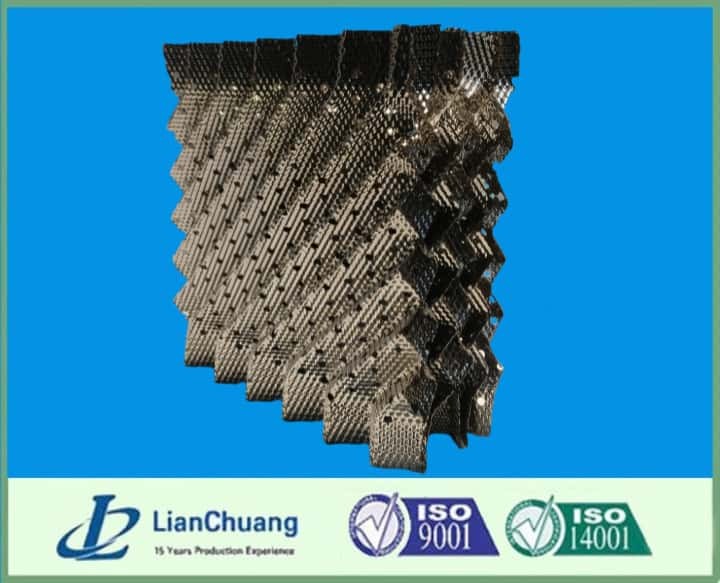

"X" Designated Packings

- 60-degree nominal inclination angle from horizontal;

- Suitable for applications requiring high capacity and low pressure drop;

- Offer lower pressure drop per theoretical stage for the same surface area.

Applications and Performance

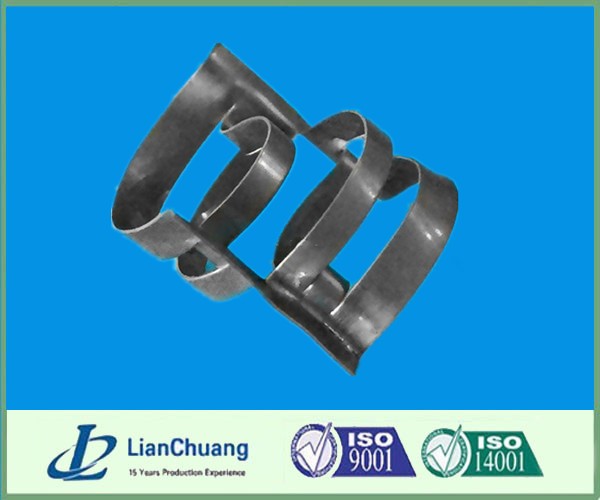

Structured Flexipac Packing has been widely utilized in numerous columns to enhance capacity and reduce pressure drop in both new constructions and as replacements for standard sheet metal structured packings, conventional random packings, and trays.

This structured packing offers excellent performance by reducing pressure drop and boosting capacity per theoretical stage. It is the preferred choice for vacuum distillation applications.

Design and Geometry Adjustments

Structured Flexipac Packing is similar in structure to Flexipac® packing, but with a modification in the corrugation geometry at both the top and bottom of each packing layer. These geometric adjustments:

- Eliminate abrupt changes in the flow direction of liquid and vapor phases at the packing layer interface;

- Prevent premature liquid buildup;

- Help maintain the low-pressure drop characteristics of structured packing across its efficient operating range.

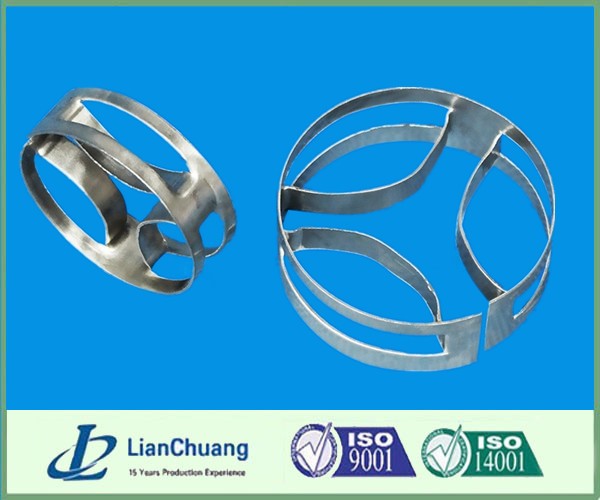

Benefits Compared to Trays and Conventional Random Packings

Compared to trays and conventional random packings, Structured Flexipac Packing delivers a lower pressure drop per theoretical stage and increases capacity.

Improvements in Columns

Columns equipped with Structured Flexipac Packing have seen the following improvements:

- Enhanced product yields;

- Improved product purity;

- Reduced reflux ratios;

- Increased throughput;

- Lower pressure drop;

- Reduced liquid hold-up;

- Enhanced heat transfer efficiency.