Product Description

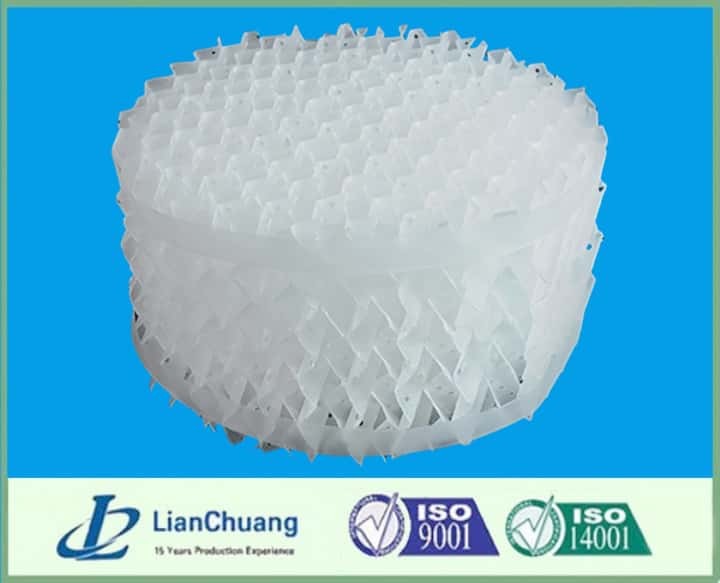

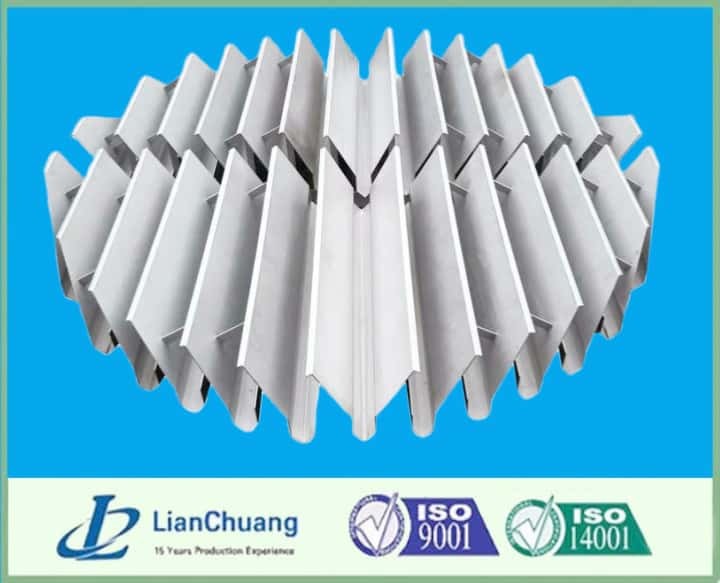

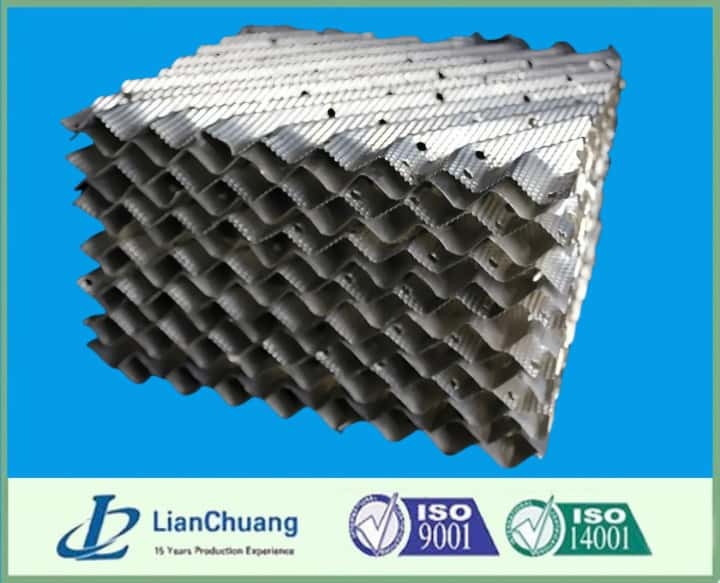

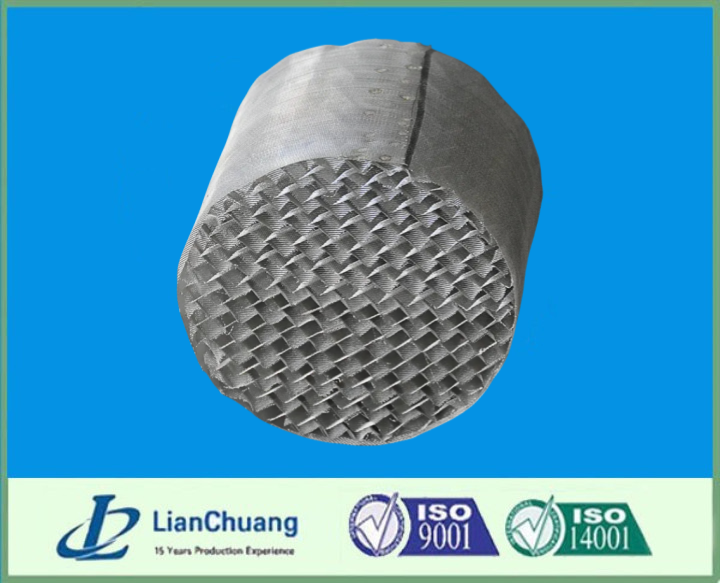

Grid structured packing combines the high surface area of traditional structured packing with the robust construction of a common grid configuration. This combination delivers excellent heat transfer efficiency, high mechanical strength, and antifouling properties, making it ideal for demanding applications prone to fouling, coking, erosion, and the presence of solids. The smooth surface minimizes liquid hold-up, reducing residence time and the potential for coke formation.

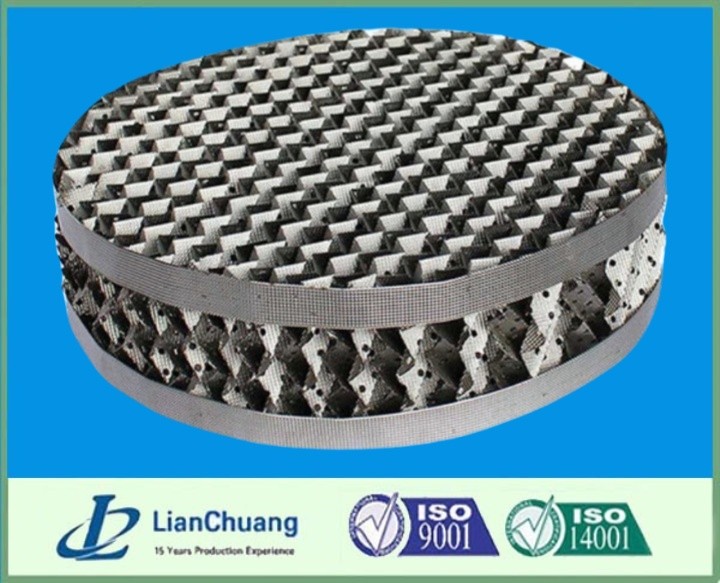

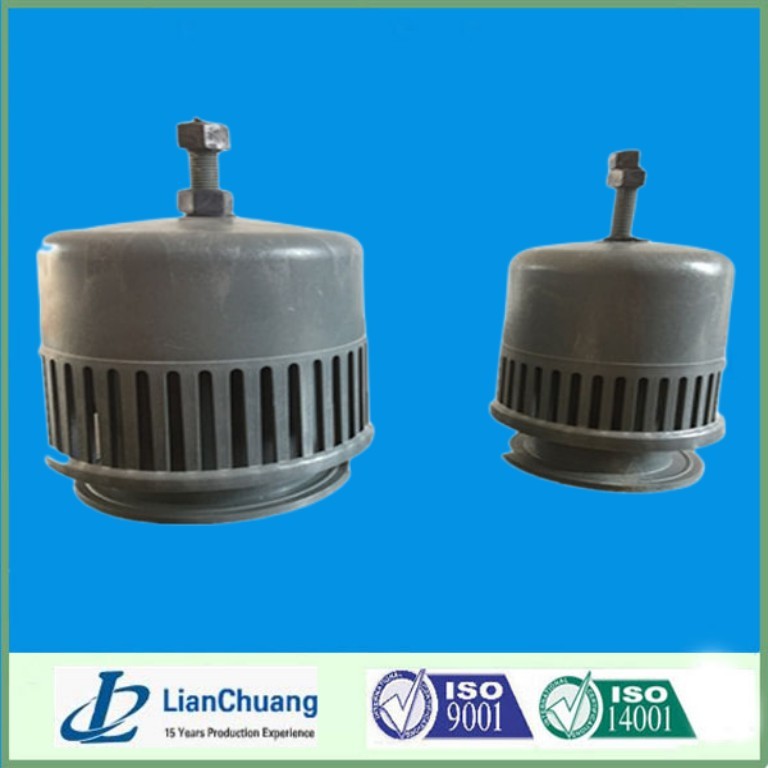

These grids are specifically designed for challenging environments where fouling, erosion, coking, and high solids content are common. They are installed in rigid modules, arranged in successive layers with a fixed orientation, which helps to reduce overall pressure drop while enhancing tower efficiency. We offer three types of grids: Mellagrid, Nutter Grid, and F-Grid.

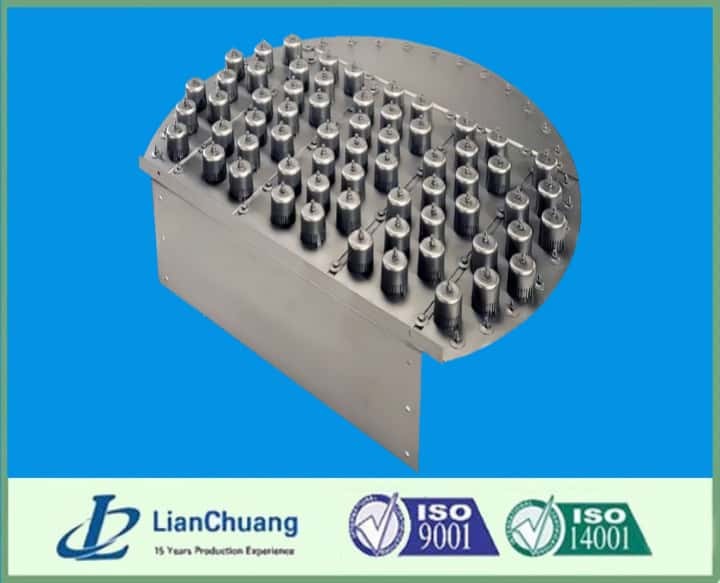

Features of Grid structured packing:

1. Ideal for coking and fouling applications due to its unique geometric structure and smooth surface.

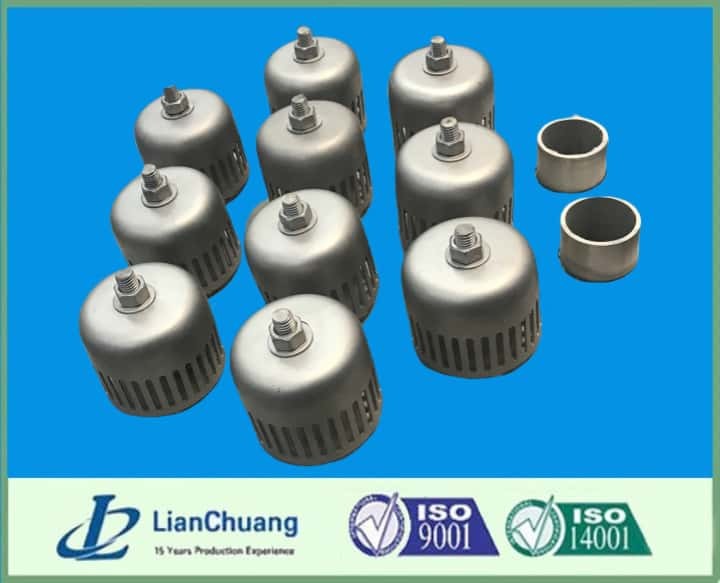

2. The design and element height facilitate easy cleaning.

3. Components can be removed, unscrewed, and cleaned using a water jet.

4. Efficient heat dissipation capabilities.

5. Structurally strong and mechanically robust.

6. Delivers superior separation efficiency compared to traditional grid structured packing.

7. Common applications include oil refineries.

Main Benefits of Grid Structured Packing:

1. Minimizes overall pressure drop, improving system efficiency.

2. Enhances tower efficiency.

3. Resistant to fouling and coking, thanks to its smooth surface and geometric structure.

4. Efficient heat dissipation, ensuring stable operation.

5. Improved de-entrainment and separation efficiency.

6. Easy to clean with simple removal and water jet cleaning.

7. Strong mechanical integrity.

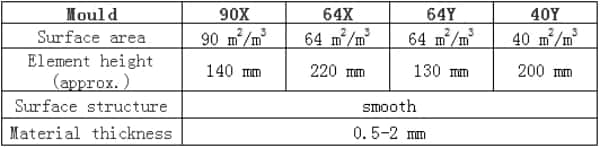

Specifications:

Applications:

1. Vacuum tower wash section.

2. Atmospheric column overflash section.

3. Fluid Catalytic Cracker (FCC) main fractionator slurry pumparound section.

4. FCC flue gas scrubber.

5. Coker main fractionator quench section.

6. Visbreaker main fractionator wash section.

7. Ethylene primary fractionator.

8. Ethylene water quench tower.