Product Description

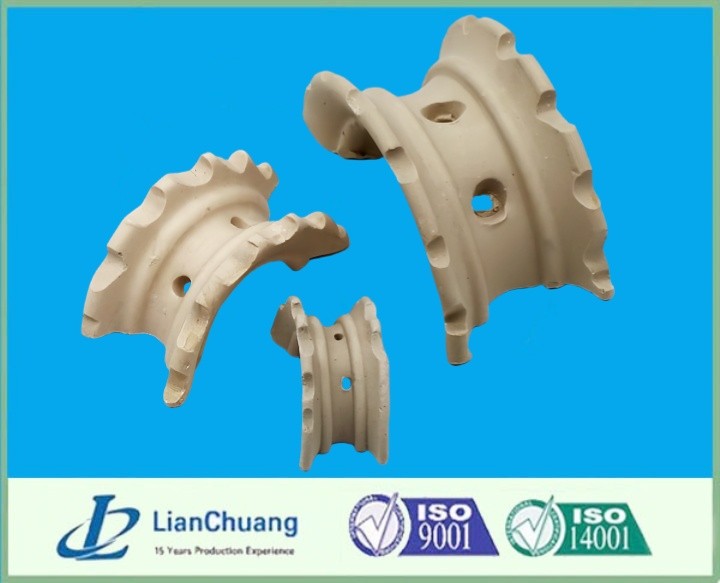

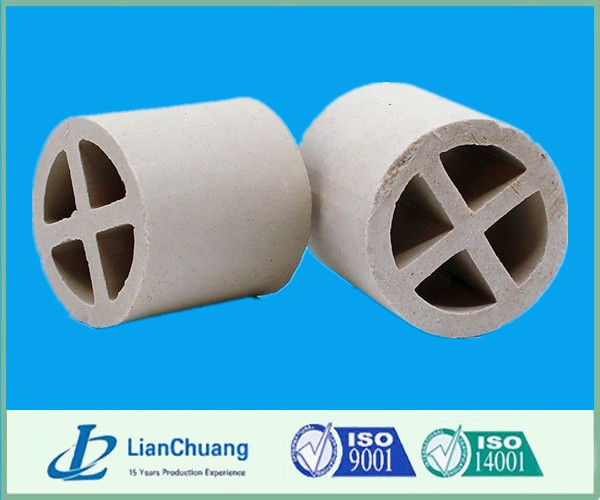

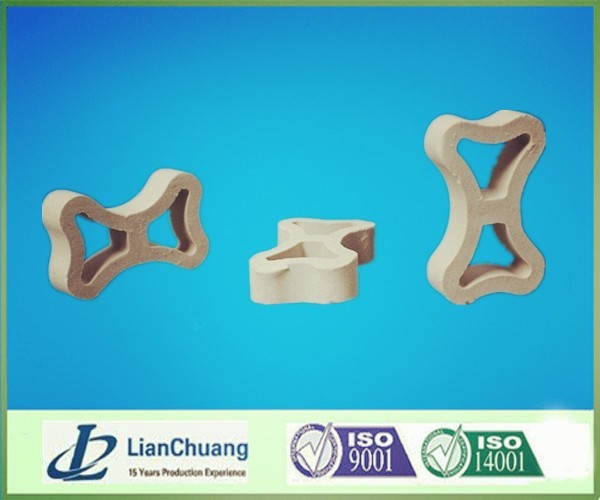

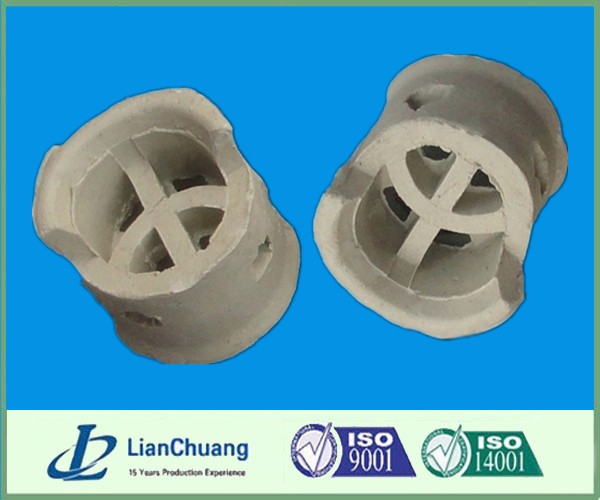

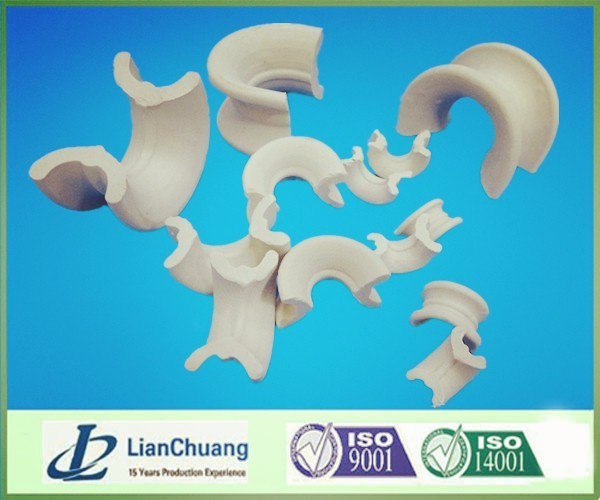

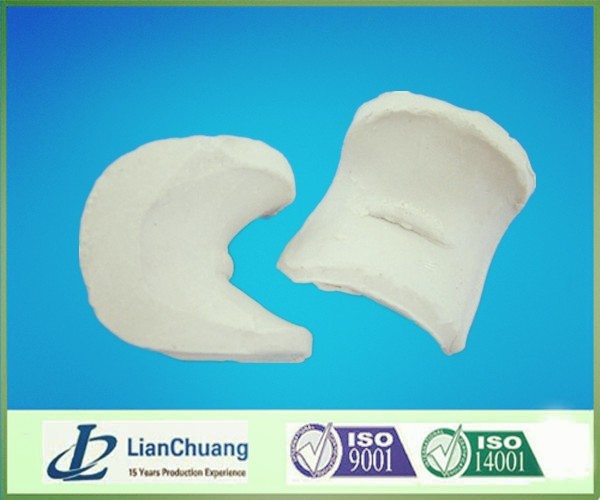

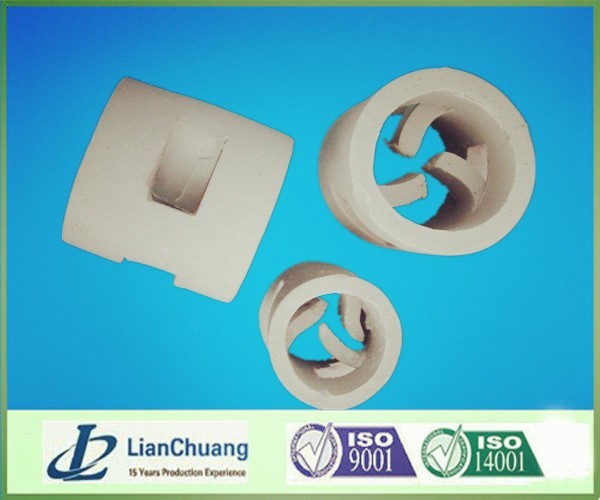

Hiflow Saddles Packings are a new and improved version of conventional saddle packings, make the smooth saddle moment to zigzag or curved side of the raised side of the grain pattern. This specifically designed to enhance fluid flow efficiency. Featuring a unique serrated edge and hole structure, these saddles significantly reduce pressure loss and increase surface area, making them highly effective in various applications.

Key Features

- Innovative Design: The serrated edge and hole structure provide a 25% reduction in pressure drop, greatly improving flow performance and efficiency.

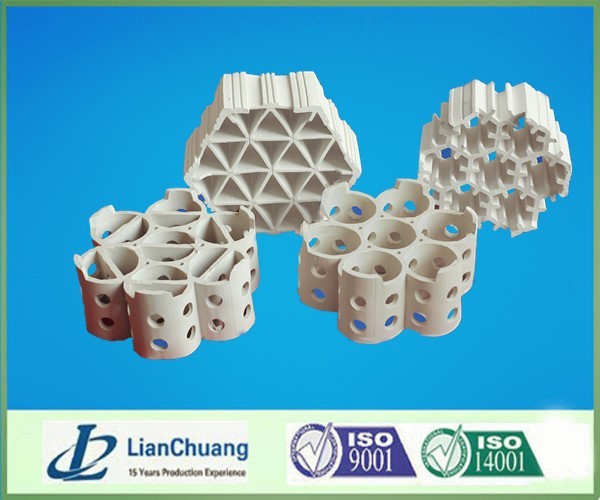

- Increased Surface Area: Hiflow® Saddles offer a 25% increase in surface area compared to standard saddle packings, enhancing gas and liquid contact efficiency.

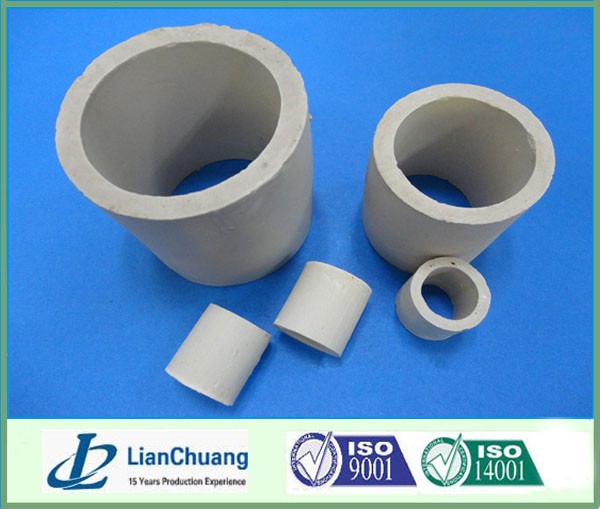

- Optimized Packing Layer: Featuring ceramic super saddle ring packing, the smooth surface has been improved to create a zigzag or curved grain pattern, increasing the gaps between contact points.

- Efficient Fluid Transfer: The optimized design facilitates better gas and liquid flow within the packing layer, reducing pressure drop while enhancing mass transfer efficiency.

- Wide Applications: Hiflow® Saddles are particularly suited for use in sulfuric acid drying towers and absorbers, delivering outstanding performance.

Specifications

Physical properties:

| Index | Unit | Value |

| Porosity | Vol% | 1 |

| Specific heat | KJ/Kg | 840-900 |

| Crush strength | N/mm2 | 390-420 |

| Specific gravity | g/cm3 | 2.3-2.45 |

| Acid Resistance | % | 99.98 |

| Firing temperature | °C | 1280 to 1320 |

| Softening point | °C | >1400 |

| Water absorption | % | <0.2< span=""> |

| Thermal Expansion | 10-6mm/mm°C | 4.7 |

Geometric properties:

| Nominal Size | Approx. Weight | Surface area | Void Fraction(%) | Dry Packing factor(m-1) | ||

| 1b/ft3 | Kg/m3 | ft2/ft3 | m2/m3 | |||

| 1" | 40 | 645 | 79.5 | 260 | 77 | 570 |

| 1.5" | 37.5 | 600 | 64 | 210 | 78 | 430 |

| 2" | 35.6 | 570 | 42.8 | 140 | 79 | 277 |

| 3" | 36 | 580 | 32 | 105 | 77 | 206 |

Typical Uses

- 1. Provides outstanding acid resistance and thermal stability.

- 2. Resistant to corrosion from a wide range of inorganic acids, organic acids, and organic solvents, except for hydrofluoric acid.

- 3. Suitable for both high-temperature and low-temperature applications.

- 4. Commonly applied in:

- Drying towers

- Absorption towers

- Cooling systems

- Scrubbing towers

- Activation columns

- Used across industries such as chemical processing, metallurgy, coal gasification, and oxygen generation.

Choose Hiflow Saddle Packings to make your industrial processes more efficient and economical. With their innovative design and superior performance, Hiflow® Saddles are the ideal solution for enhancing fluid handling efficiency.