Product Description

In the landscape of industrial cooling solutions, Hybrid-Fluted Fills emerge as an innovative product that bridges the gap between traditional fills and high-efficiency cooling systems. As industries push towards more efficient and cost-effective operations, there is a pronounced need for advanced materials that can deliver superior performance with minimal maintenance. PVC Hybrid Fluted Film Fills For Cooling Towerare developed to address these requirements, providing a sophisticated alternative to standard vertical-fluted and offset-fluted fills.

Origin and Development of Hybrid Fluted Fills

The concept of PVC Hybrid Fluted Film Fillsstems from the need to enhance thermal efficiency and reduce operational challenges associated with traditional cooling tower fills. While Vertical Fluted Fills are effective to some extent, they often suffer from issues related to fouling and suboptimal water distribution. offset fluted fills offer improvements in these areas but still fall short of providing the maximum cooling potential sought by modern industries. Recognizing these limitations, engineers and material scientists embarked on creating a product that amalgamates the best features of existing designs while introducing novel structural enhancements. The result is the Hybrid-Fluted Fill, meticulously crafted to optimize heat transfer, minimize fouling, and ensure uniform water distribution across the cooling tower fill medium.

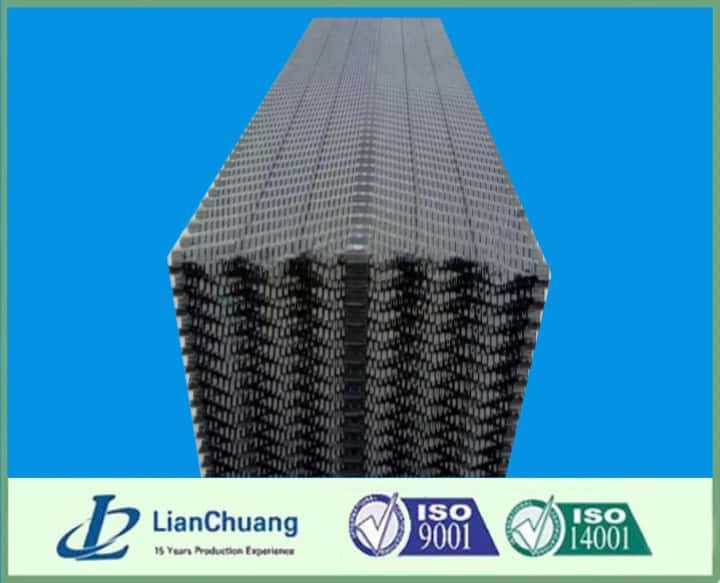

Hybrid Fluted Fill Basic Structure and Design Elements

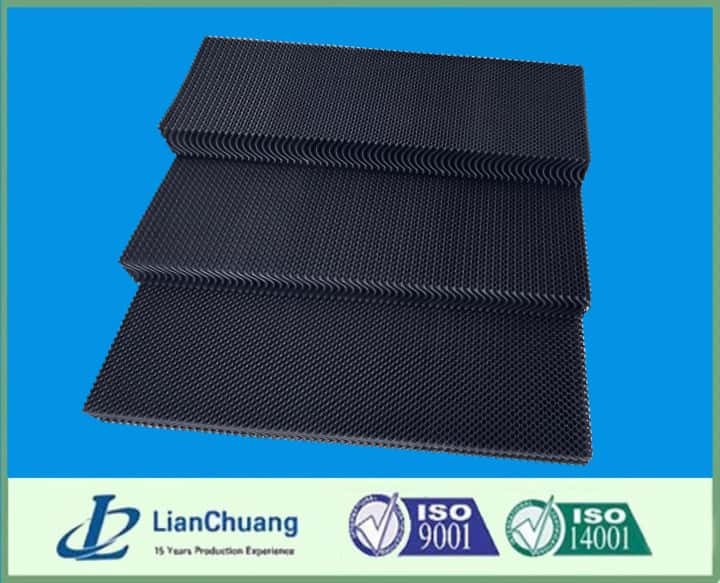

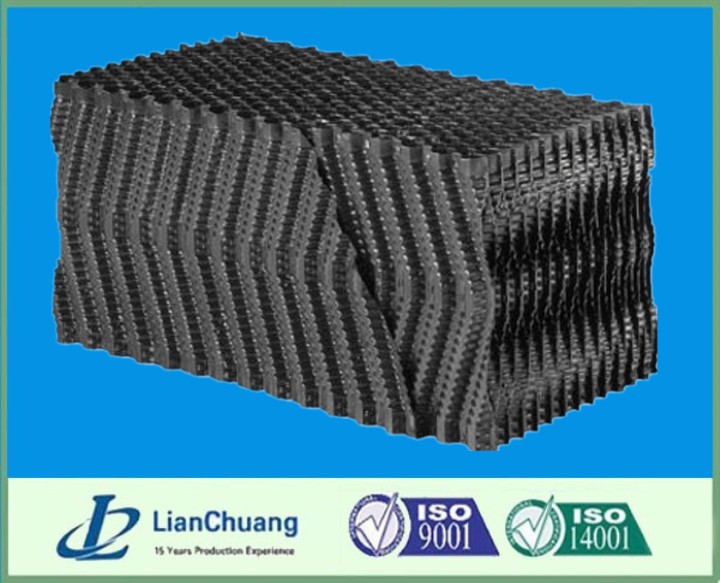

At the core of Hybrid Fluted Fills is their distinctive structural design, which sets them apart from other fill types. The hybrid approach involves a synergistic integration of vertical and inclined flutes within the fill medium. This innovative design ensures that water flows more efficiently through the fill, enhancing heat exchange and improving overall cooling performance.

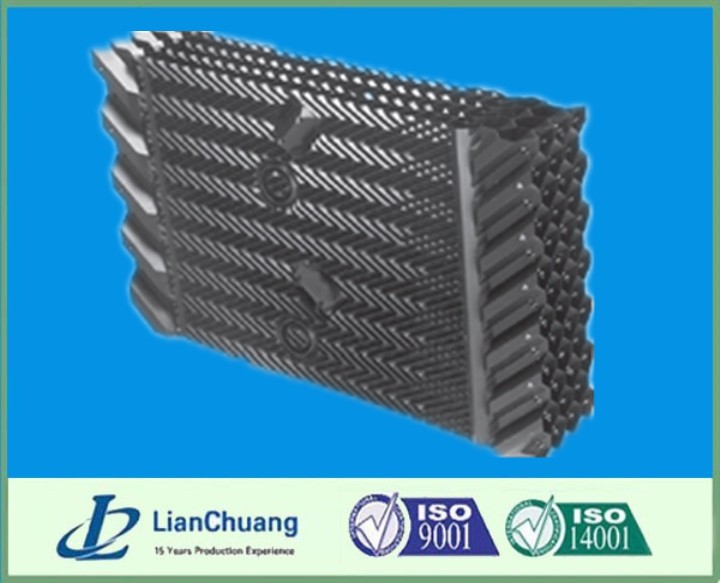

Flute Configuration:

1.Vertical Flutes: The vertical components of Hybrid-Fluted Fills facilitate direct downward water flow, leveraging gravity to enhance the speed and efficiency of water distribution.

2.Inclined Flutes: The inclined flutes are strategically positioned to intercept and redirect water, creating a turbulent flow that maximizes surface contact between the water and the air. This turbulence increases the rate of heat transfer, thereby boosting cooling efficiency.

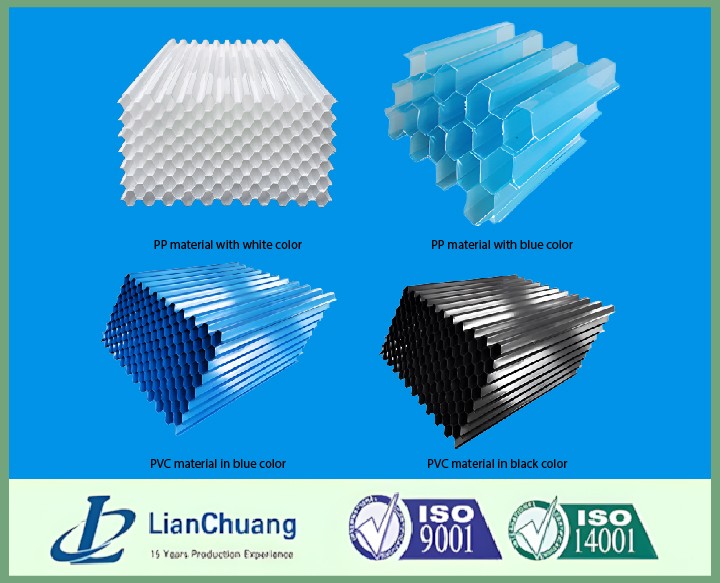

Material Composition:

Hybrid-Fluted Fills are typically constructed from high-quality PVC (polyvinyl chloride) or other thermoplastics known for their durability and resistance to chemical degradation. The material's properties ensure long-term performance and minimal maintenance, even in harsh industrial environments.

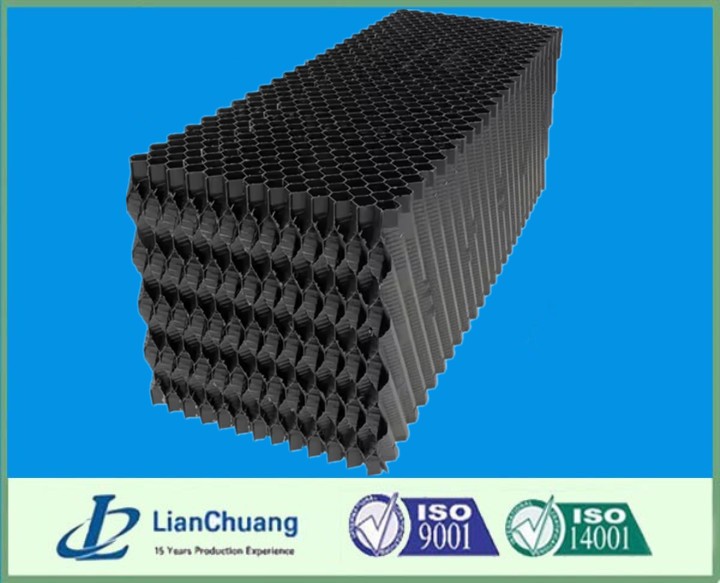

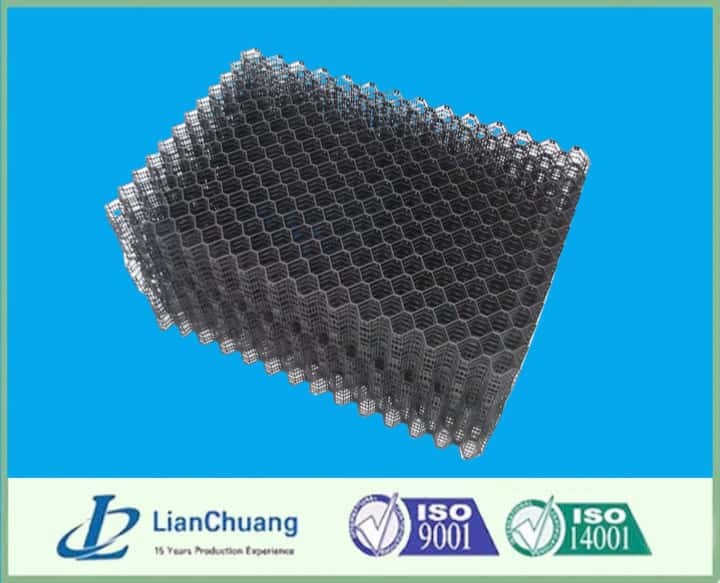

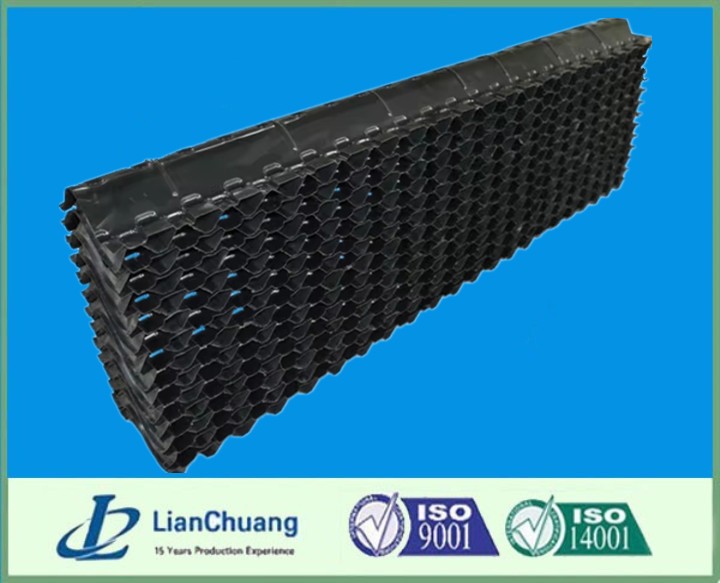

Honeycomb Structure:

The honeycomb-like structure of Hybrid-Fluted Fills provides a robust framework that supports the water distribution process. This design not only enhances mechanical stability but also optimizes the fill medium's surface area, allowing for more effective heat dissipation.

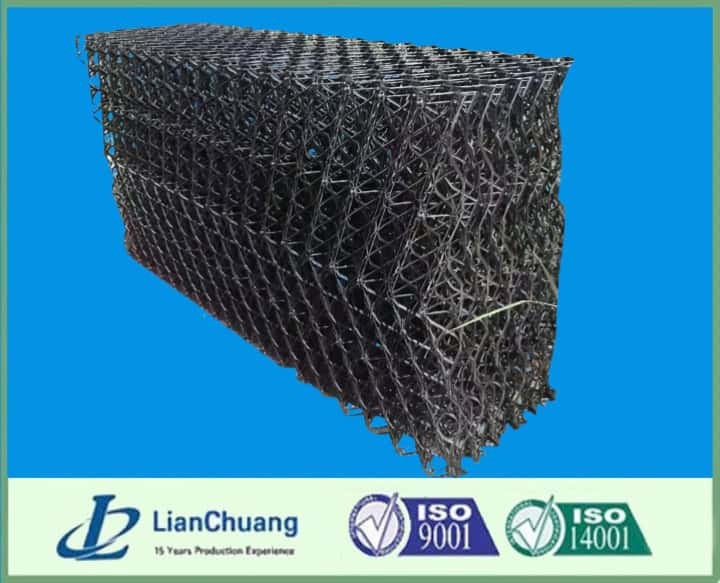

Anti-Fouling Design:

One of the critical challenges in cooling tower fills is the accumulation of debris and biological growth, which can impede performance. Hybrid-Fluted Fills are engineered with an anti-fouling design that reduces the likelihood of clogging. The smooth surfaces and strategic placement of flutes prevent the buildup of contaminants, ensuring consistent operation.

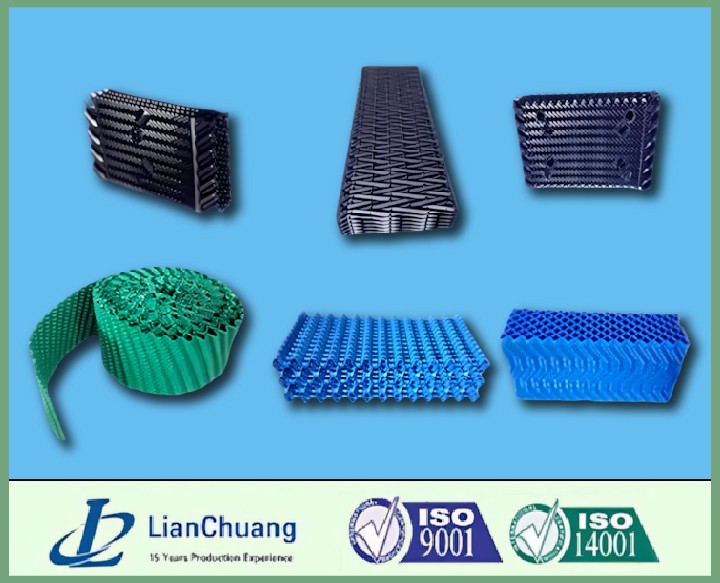

Modular Construction:

To accommodate various cooling tower configurations, Hybrid-Fluted Fills are designed in modular sections. This modularity allows for easy installation, replacement, and scaling, making it adaptable to different industrial applications and cooling tower sizes.

Unique Features of Hybrid-Fluted Fills

Hybrid-Fluted Fills stand out in the realm of cooling solutions due to their unique combination of advanced design features and robust material composition. These features are meticulously engineered to enhance both the thermal performance and the operational reliability of cooling towers.

Advanced Fluted Design: The core of Hybrid-Fluted Fills is their innovative fluted design, which ingeniously combines vertical and inclined flutes to optimize the cooling process.

Material Robustness and Durability: The materials used in Hybrid-Fluted Fills are known for their high durability and resistance to environmental and chemical stresses.

Design Elements for Improved Fluid Dynamics: The unique structure of Hybrid-Fluted Fills goes beyond just the arrangement of flutes; it includes several design elements that improve fluid dynamics and overall performance.

Superior Thermal Performance: The combination of advanced fluted design, robust materials, and optimized fluid dynamics culminates in superior thermal performance, setting Hybrid-Fluted Fills apart from traditional fill types.

Benefits of Using Hybrid-Fluted Fills

The primary advantages of Hybrid-Fluted Fills lie in their enhanced efficiency, cost-effectiveness, and environmental benefits.

1. Reduction in Energy Consumption: Hybrid-Fluted Fills can significantly reduce energy consumption, thanks to their optimized design, which enhances heat transfer efficiency and minimizes resistance within the cooling tower system.

2. Lower Operational Costs: The adoption of Hybrid-Fluted Fills can lead to significant reductions in operational costs. These savings are realized through a combination of lower maintenance requirements, extended fill lifespan, and improved overall system efficiency.

3. Contribution to Sustainable Practices: In an era where sustainability is paramount, Hybrid-Fluted Fills offer several environmental benefits. These advantages not only help industries comply with environmental regulations but also promote eco-friendly practices.

Applications of Hybrid-Fluted Fills

Hybrid-Fluted Fills have versatile applications across various industries, including power generation, chemical processing, and water treatment. Below are the utilizations of these fills in key sectors:

Power Generation: In the power generation sector, Hybrid-Fluted Fills offer significant improvements in cooling systems.

Chemical Processing: Hybrid-Fluted Fills are invaluable in chemical processing plants due to their ability to provide efficient cooling for complex thermal management systems.

Water Treatment: In water treatment facilities, Hybrid-Fluted Fills help enhance system performance and sustainability.