Product Description

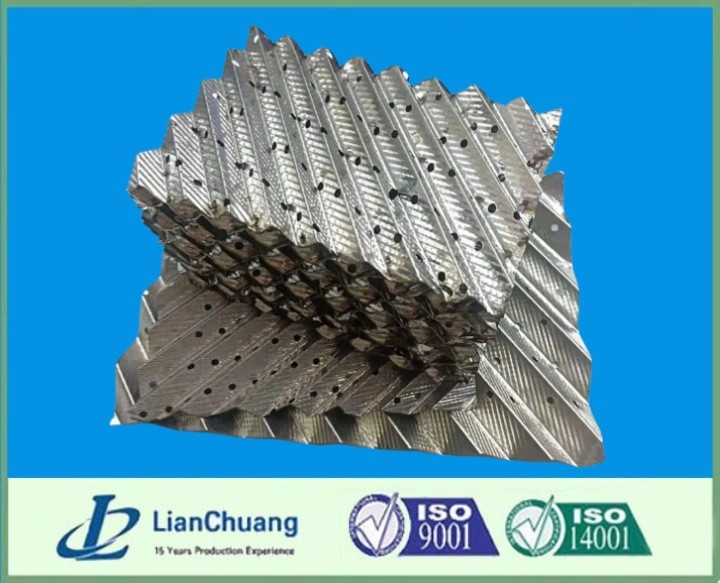

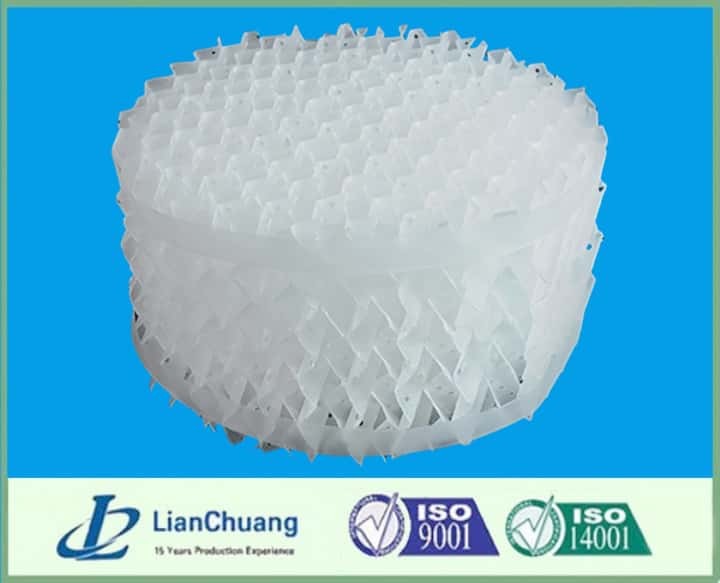

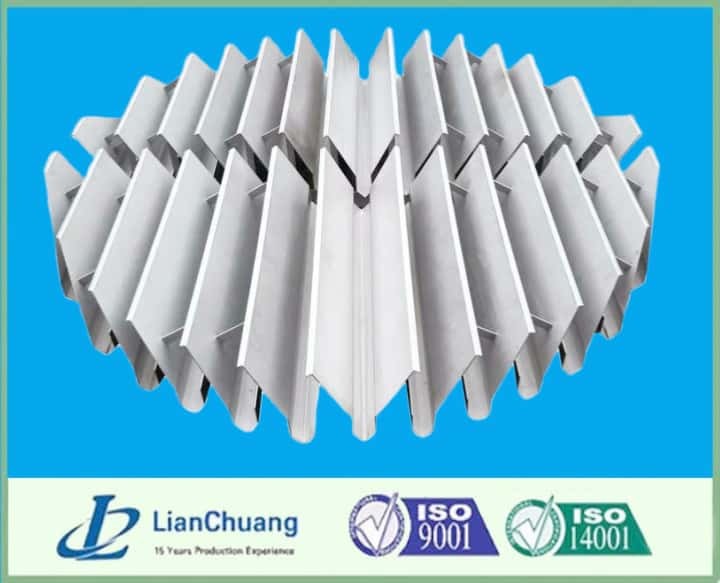

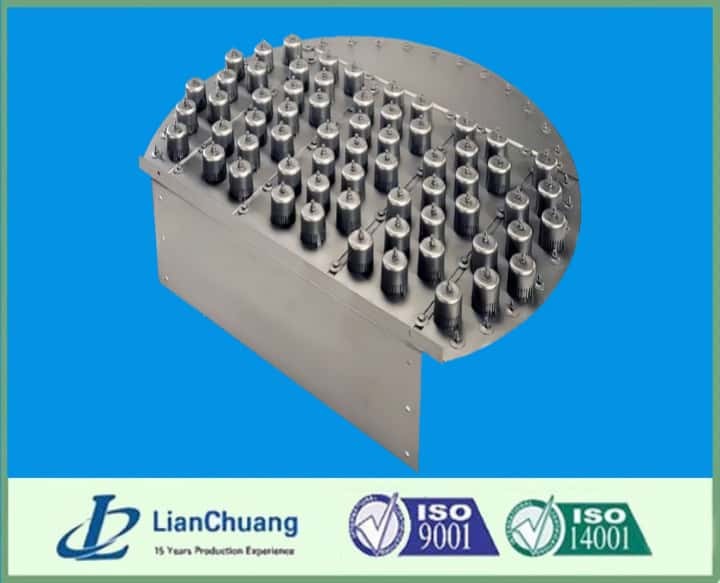

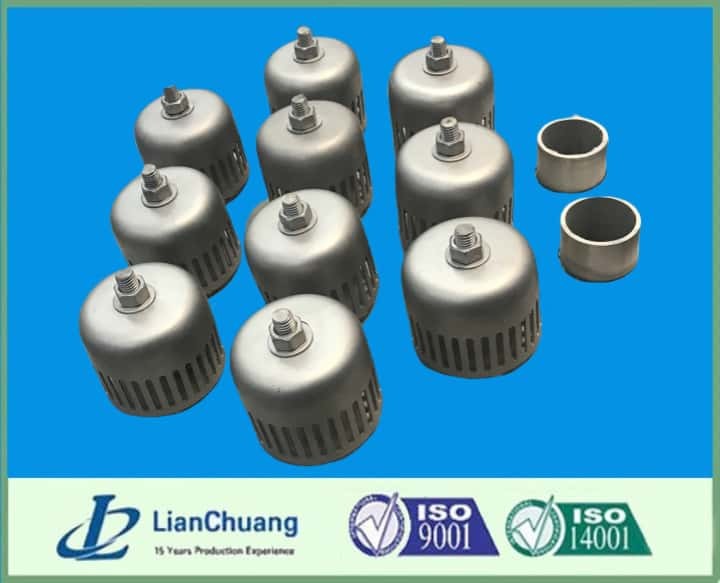

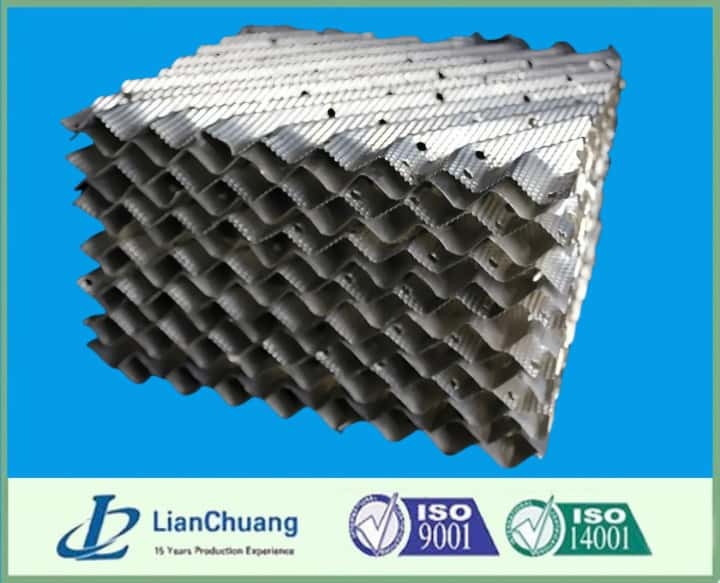

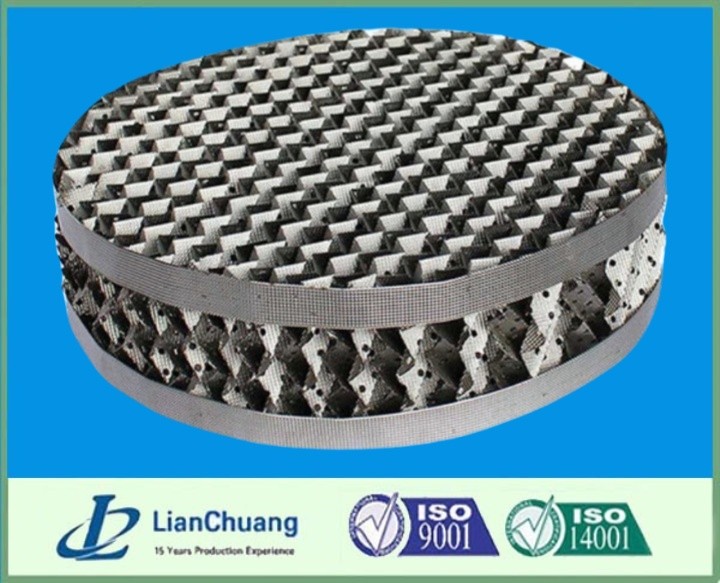

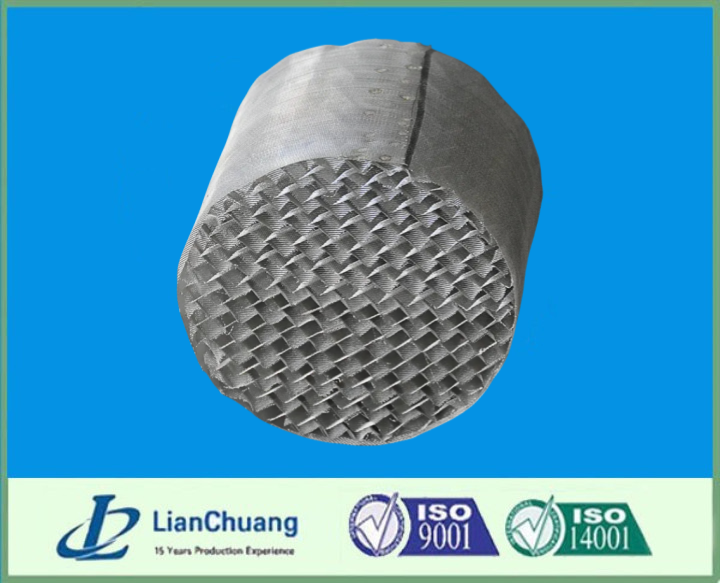

Metal Intalox Structured Packing is a highly efficient mass transfer medium designed from perforated plates with surface corrugations, similar in structure to metal wire gauze packing. These features enhance uniform liquid distribution and surface wetting, resulting in improved mass transfer efficiency. The packing is typically produced in coils with a unit height of 50-200 mm, and for columns with diameters larger than 1.5 meters, it is delivered in blocks for easy installation.

Key Advantages:

Customizable Geometries: Intalox structured packing offers a wide range of geometrical shapes and surface structures, making it adaptable to various industrial needs.

High Flux and Low Resistance: The packing’s design allows for increased distillation efficiency due to high throughput and minimal resistance to fluid flow.

Low Pressure Drop: This feature significantly reduces energy consumption, making it an energy-efficient choice for separation processes.

Flexibility: The packing maintains high performance across different scales, ensuring operational flexibility without significant performance losses.

Customization: It can be tailored to suit specific types of packing requirements, offering versatility for various applications.

Specifications:

Model | Surface area M2/m3 | Void fraction % | Peak height | Peak distance | ||

#64X,Y | 64 | 99 | 47 | ±2.0 | 83 | ±3 |

#100X,Y | 100 | 99 | 32 | ±1.0 | 50 | ±2 |

#125X,Y | 125 | 98 | 23 | ±1.0 | 43 | ±2 |

#150X,Y | 150 | 98 | 20 | ±1.0 | 35.5 | ±1 |

#170X,Y | 170 | 98 | 19 | ±0.9 | 30 | ±1 |

#175X,Y | 175 | 98 | 18.5 | ±0.9 | 29 | ±1 |

#200X,Y | 200 | 98 | 16 | ±0.8 | 25 | ±1 |

#220X,Y | 220 | 98 | 14.3 | ±0.8 | 23.2 | ±1 |

#250X,Y | 250 | 97 | 12 | ±0.5 | 21 | ±1 |

#300X,Y | 300 | 96 | 10.4 | ±0.4 | 16.8 | ±1 |

#350X,Y | 350 | 94 | 9 | ±0.4 | 14.5 | ±1 |

#400X,Y | 400 | 94 | 8 | ±0.4 | 12.8 | ±0.8 |

#450X,Y | 450 | 94 | 6.7 | ±0.3 | 11.8 | ±0.5 |

#500X,Y | 500 | 93 | 6.3 | ±0.3 | 10.2 | ±0.5 |

#550X,Y | 550 | 93 | 5.7 | ±0.3 | 9.4 | ±0.3 |

#700X,Y | 700 | 90 | 4.3 | ±0.2 | 7.6 | ±0.3 |

#1000X,Y | 1000 | 90 | 3 | ±0.2 | 5.3 | ±0.3 |

The superior performance of Intalox structured packing is attributed to several design features, including its aggressively textured surface, corrugation reversals in each packing layer, and other proprietary geometric enhancements. These elements contribute to its success in high-liquid-rate and high-pressure systems, as well as in standard vacuum and atmospheric processes.

Intalox structured packing is particularly effective in aqueous distillation applications, where its textured surface ensures excellent surface wetting. Its larger corrugation crimp sizes provide notable advantages, such as:

Superior Efficiency: Compared to other structured packings with similar surface areas, Intalox offers better separation efficiency.

Excellent Capacity and Pressure Drop Characteristics: The unique design enables high capacity while maintaining favorable pressure drop, which is essential for optimizing energy use and system performance.

In summary, Metal Intalox Structured Packing is a highly efficient, customizable solution for a wide range of distillation and separation processes, offering significant advantages in both performance and energy savings.