Product Description

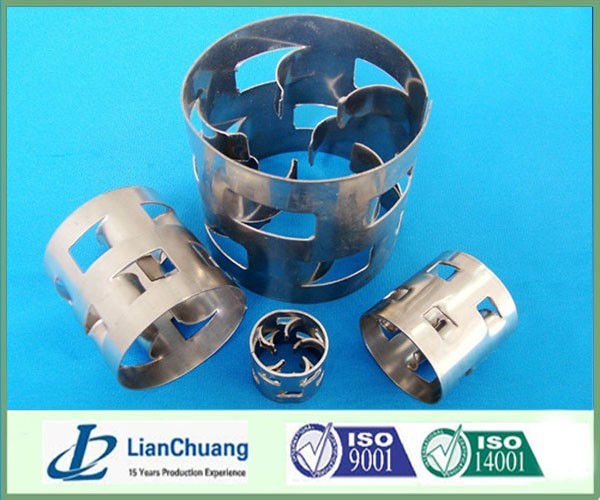

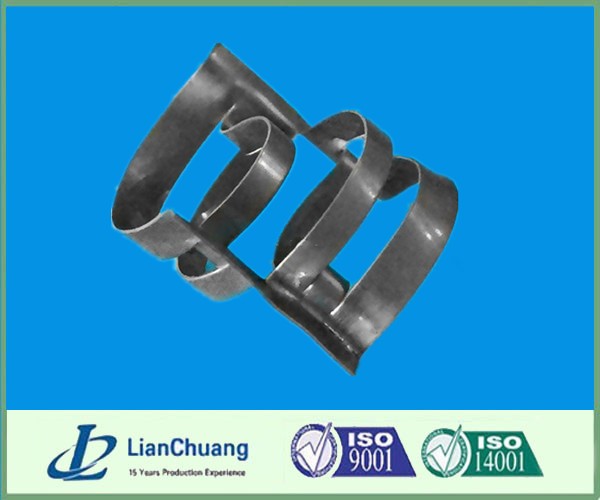

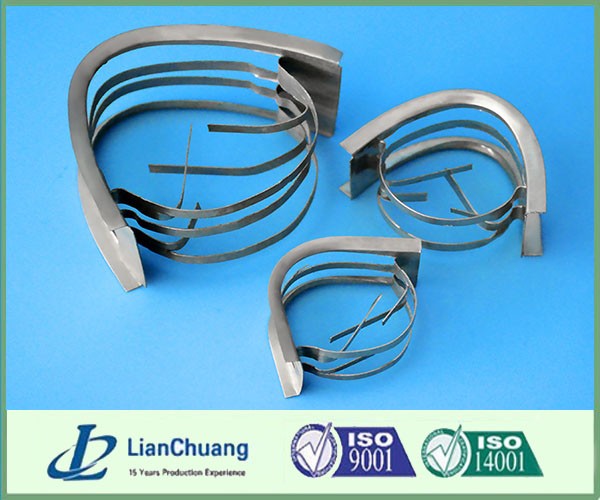

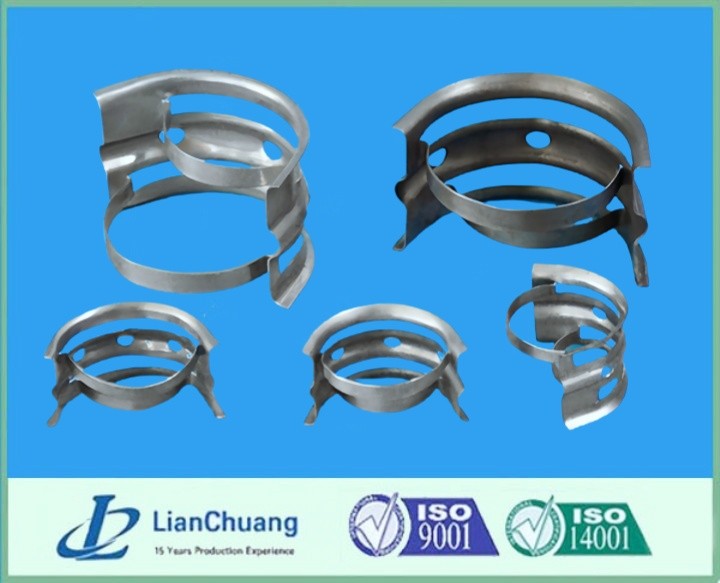

Metal pall ring is an advancement on the raschig ring, it's a open-hole ring packing, metal pall ring has similar cylindrical dimensions but has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop, better than raschig ring. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the metal pall ring geometry enables high gas and liquid transfer rates. The interior and exterior contacting surfaces of the metal pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting. metallic pall rings are available in a wide range of materials, such as carbon steel, stainless steel: SS304, 304L, SS400, 410,316, 316L etc.

Metal pall ring is an advancement on the raschig ring, it's a open-hole ring packing, metal pall ring has similar cylindrical dimensions but has two rows of punched out holes, with fingers or webs turned into the centre of the cylinder, which significantly increases the performance of the packing, in terms of throughput, efficiency and pressure drop, better than raschig ring. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the metal pall ring geometry enables high gas and liquid transfer rates. The interior and exterior contacting surfaces of the metal pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting. metallic pall rings are available in a wide range of materials, such as carbon steel, stainless steel: SS304, 304L, SS400, 410,316, 316L etc.

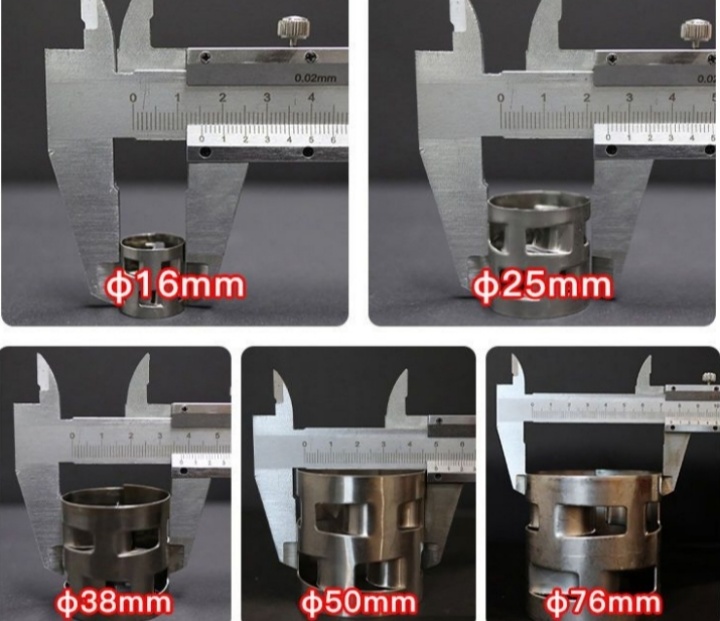

Metal Pall Ring product model:

6mm(1/4"), 10mm(3/8"), 16mm(5/8"), 25mm (1") ,38mm(1.5"),50mm(2"),76mm(3")

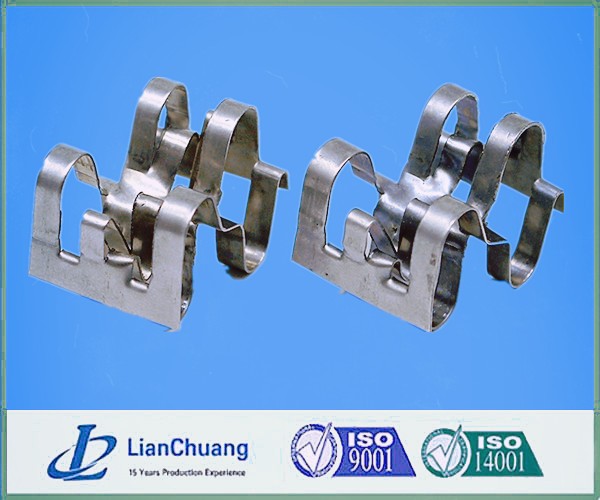

Features of metal pall ring:

Capacity vs Pressure Drop: Metal pall ring has high loading and throughput with low pressure drop character, and metal pall ring has good liquid and gas distribution and also high mass transfer efficiency.

Versatility: Metal pall ring can be easily wettabl, and has high resistance to fouling and high temperature

Mechanical Strength: Metal pall ring’s high mechanically robust, lesser probability of breakage make it could be suitable for deeper beds.

Advantages of Metal Pall Rings include:

1. Enhanced loading capacity and throughput while maintaining minimal pressure drop.

2. Superior wetting characteristics compared to plastic alternatives.

3. Improved mass transfer efficiency and uniform distribution of liquids and gases.

3. Versatility across various applications with excellent resistance to fouling.

4. Exceptional mechanical strength, ensuring prolonged lifespan and reliability.

5. Suitable for high-temperature environments and resistant to corrosion in acidic, alkaline, high-salt, and other harsh conditions.

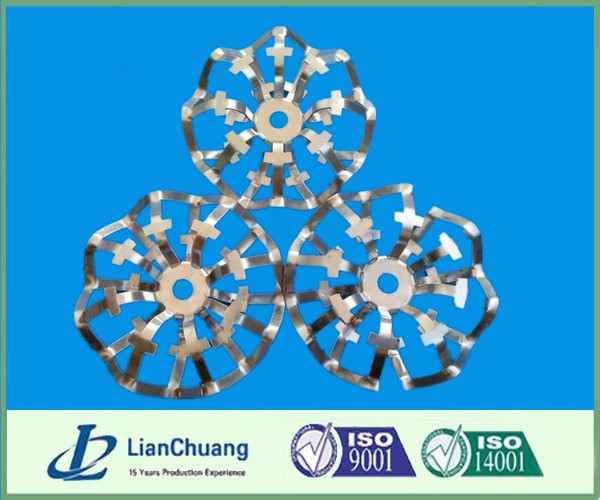

Application of metal pall ring:

Metal Pall Ring Packing has extensive application across a variety of industries including separation, absorption plants, vacuum systems, ammonia production, decarburization, desulfurization, and the separation of compounds like ethyl benzene and methylbenzene.

It is utilized for processes such as absorption, aeration, degassing, desorption, distillation, stripping, heat recovery, and extraction, both at atmospheric pressure and under vacuum conditions where minimal pressure drop is crucial. Specific uses include H2S, NH3, and SO2 absorption and stripping, steam stripping, quench towers, and direct contact cooling.

Metal Pall Ring Specification:

Size | Specification | Surface area | Void space | Bulk density | No.elements | Packing factor | |

inch | mm | mm | m2/m3 | % | kg/m3 | per/m3 | m-1 |

5/8 “ | 16mm | 16*16*0.3mm | 362 | 94.9 | 396 | 214000 | 423 |

1 “ | 25mm | 25*25*0.5mm | 219 | 95 | 393 | 51940 | 269 |

1.5 “ | 38mm | 38*18*0.6mm | 146 | 95.9 | 318 | 15180 | 165 |

2 “ | 50mm | 50*50*0.8mm | 109 | 96 | 314 | 6500 | 124 |

3 “ | 76mm | 76*76*1mm | 71 | 96 | 308 | 1830 | 80 |

Note:

Material could be carbon steel, special alloys, aluminum, titanium,stainless steel such as SS304, 304L, 410,316, 316L.

Ohter thickness can be produced as customer's request.

Production & Pacakge :

Package: Wooden Case, Ton Bag, Carton as request.

Our company has been specializing in the production of metal pall rings and other chemical packing products for over 15 years. Feel free to contact us for inquiries