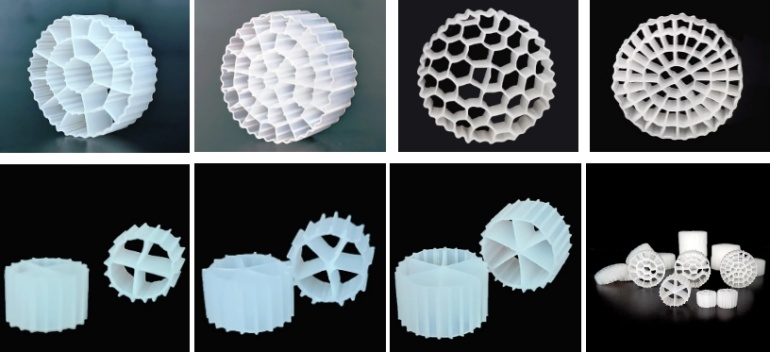

Product Description

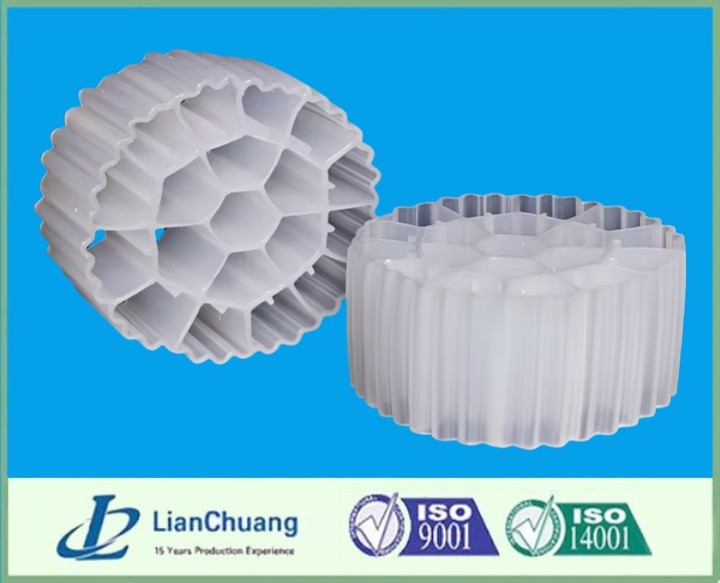

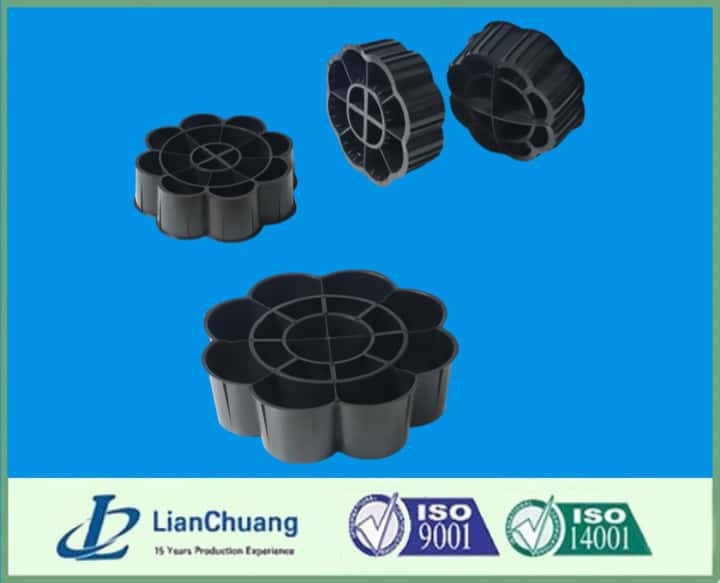

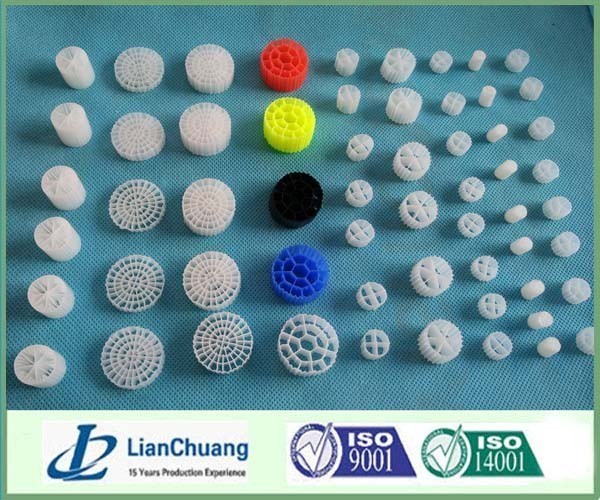

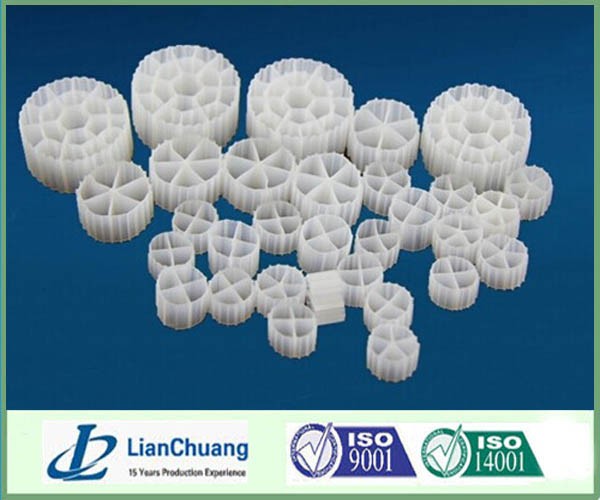

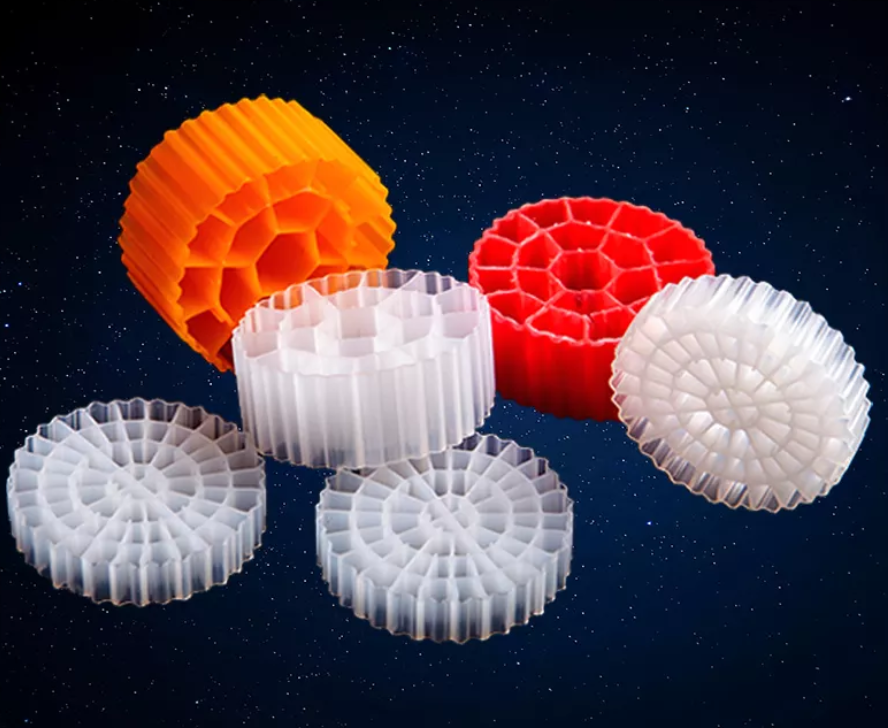

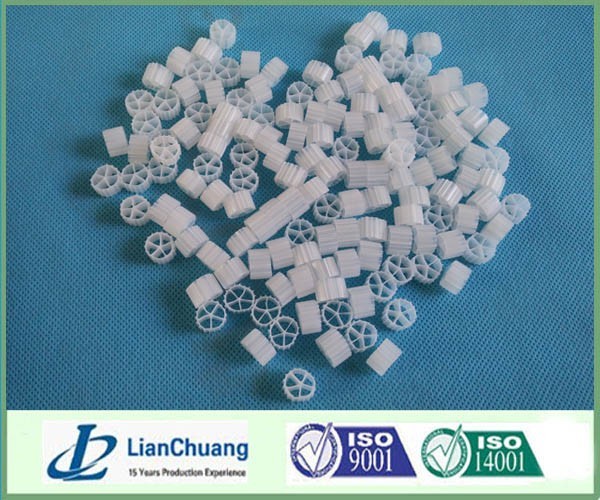

The Moving Bed Bioreactor (MBBR) consists of a tank with submerged, floating plastic media (typically made of HDPE, polyethylene, or polypropylene) with a specific gravity of less than 1.0. This moving bed bioreactor media provides a large surface area that fosters bacterial growth. Biomass attaches to the media surface, forming a biofilm typically 50 to 300 microns thick. Each media carrier enhances productivity by providing a protected surface for heterotrophic and autotrophic bacteria, thereby increasing biodegradation efficiency while ensuring process reliability and ease of operation.

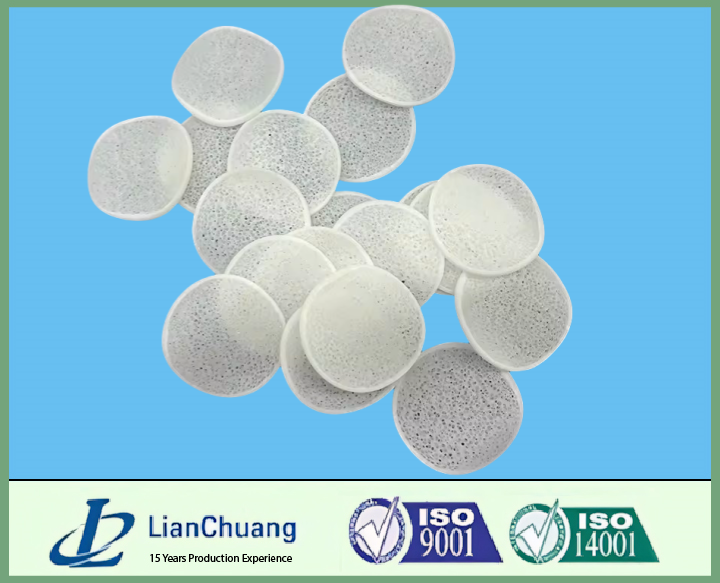

moving bed bioreactor media is a novel bioactive carrier formulated to blend beneficial microorganisms based on water characteristics. These microorganisms quickly attach and grow on trace elements embedded in the polymer material. Through specialized modification, the media gains increased surface area, excellent hydrophilicity, high biological activity, rapid biofilm formation, and resistance to environmental shocks.

In MBBR water treatment, moving bed bioreactor media also serves as an innovative bioactive carrier. Its unique structure supports anaerobic bacteria growth within the carrier for denitrification and aerobic bacteria growth on the surface for organic matter degradation, facilitating both nitrification and denitrification.

This versatile moving bed bioreactor media is widely applied in MBBR sewage treatment systems, aquaculture farms, koi ponds, and similar settings. Made from high-density polyethylene, moving bed bioreactor media creates an ideal environment for beneficial microorganisms, enabling them to attach to embedded trace elements, fostering microbial growth and organic matter degradation. Its key advantages include a large surface area, excellent hydrophilicity, high biological activity, rapid biofilm formation, effective treatment performance, and long service life.

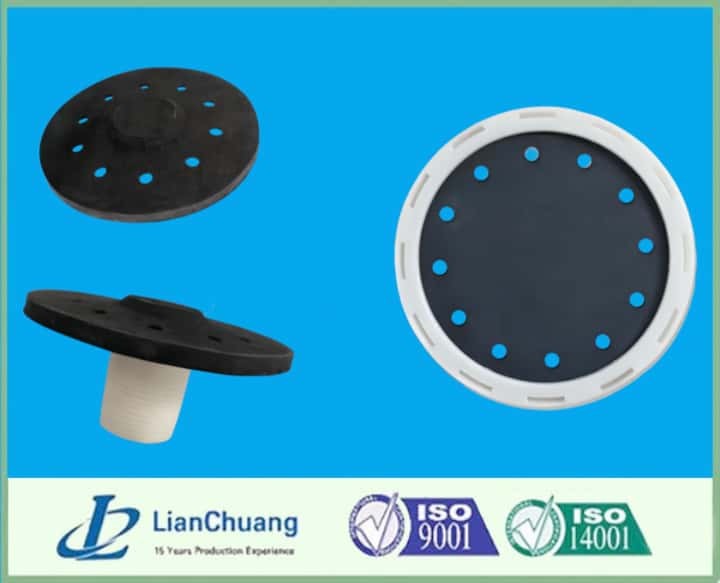

Moving bed bioreactor media is essential in both fluidized bed biofilm reactors (FBBR) and MBBR systems. Microorganisms attach to the moving plastic carriers to form biofilms. Aeration transfers oxygen into the water, mixing the media and water to support bacterial growth, which absorbs, oxidizes, and reduces organic and inorganic materials, achieving effective wastewater treatment.

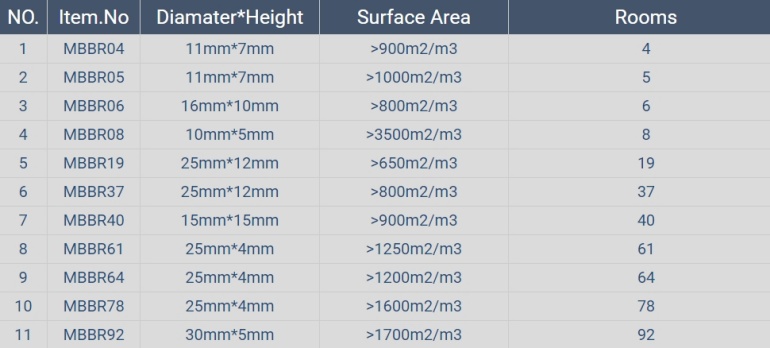

Specifications:

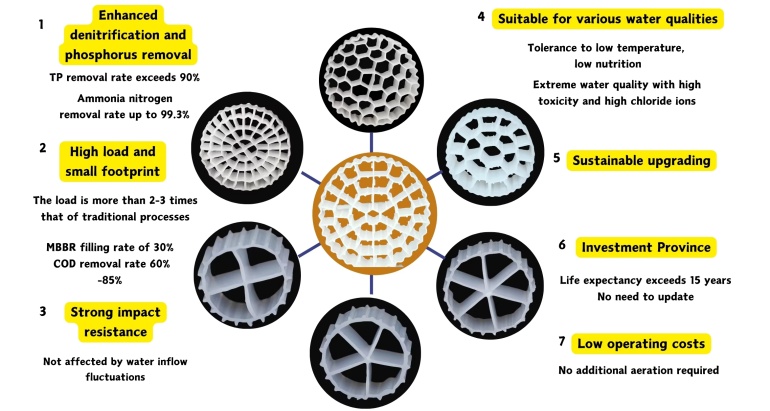

Key Features:

- Scientific Formula and Process: Accelerates biofilm formation.

- Large Surface Area: Provides extensive surface for microorganism attachment.

- Biofilm-Based Treatment: Eliminates the need for sludge return.

- High Decarbonization and Ammonia Nitrogen Removal: Effectively enhances water quality.

Advantages :

- Simple construction with quick biofilm formation and rapid startup.

- Long biological chains, diverse microbial populations, and high catalytic efficiency.

- Efficient carbon removal with strong load resistance.

- Excellent denitrification and phosphorus removal capabilities.

- Minimal residual sludge production.

- Compact design for smaller plant footprint.

- Easy to operate and manage.

- Low maintenance requirements.

- Flexible filler dosing tailored to water quality and process specifics, adaptable for aerobic, anaerobic, and anoxic tanks.

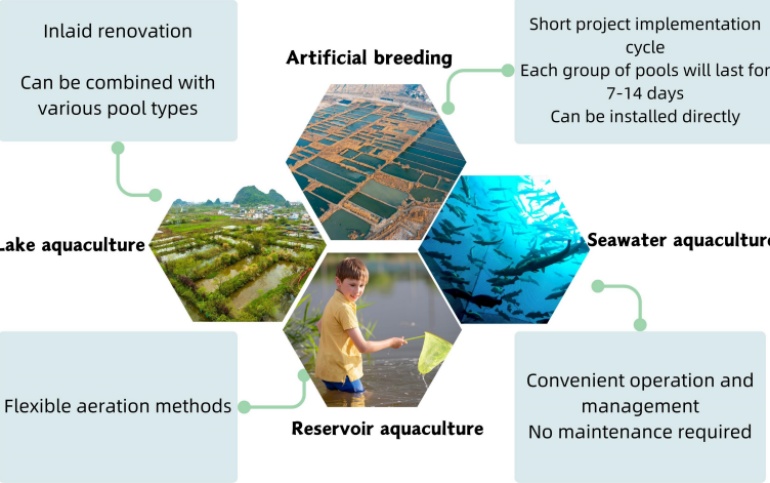

Moving Bed Bioreactor Media Applications:

- Upgrades to existing sewage treatment facilities.

- New MBBR and BAF sewage treatment projects.

- Ammonia nitrogen removal and water purification in aquaculture.

- Biochemical treatment of reclaimed water.

- Nitrogen and phosphorus removal in river systems.

- Biological filters for deodorization towers.

- Wide range of industrial applications.

Package :

- Our facory have over 10 years of experience in the production and sale of high-quality moving bed bioreactor media. Welcome contact us for reliable solutions tailored to your wastewater treatment and aquaculture needs.