Product Description

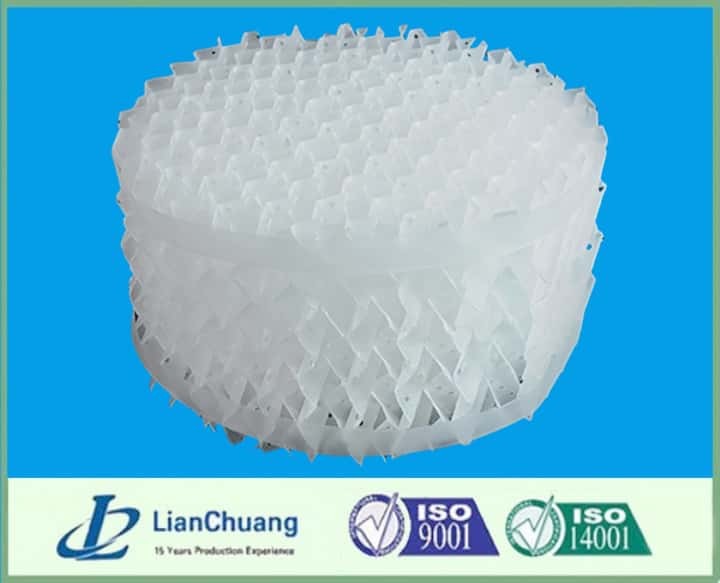

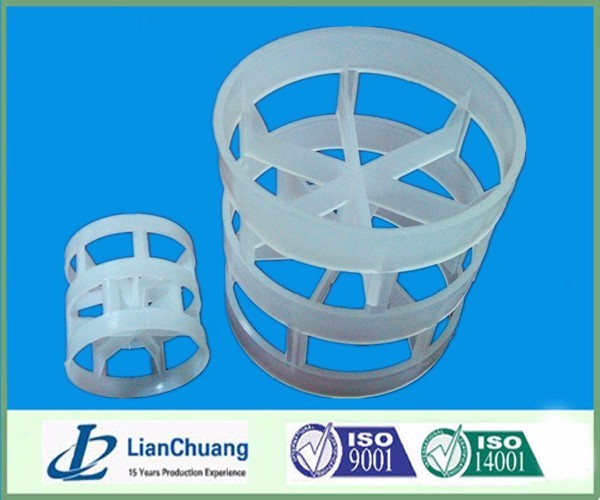

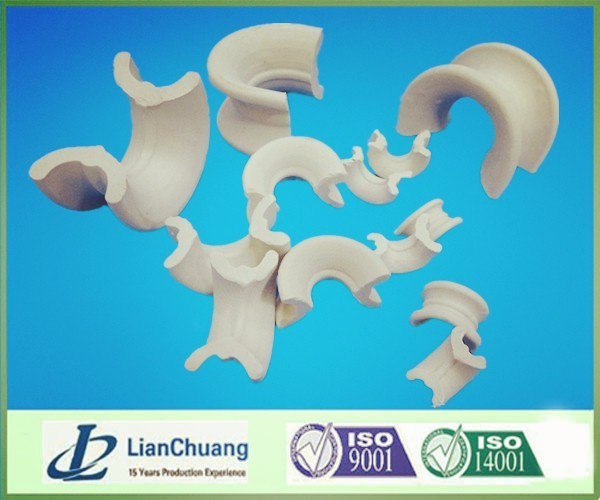

pall ring media is the second generation random packing, it's developed on the basis of the raschig ring packing. packing pall ring media rings is to open one or two layers of rectangular holes in the sidewall,and the base material of the holes is not out of the sidewall but forms inward bending of blade.The same size of Pall ring and Raschig ring have the same surface area and porosity,but thePTFE pall ring’s holes on its sidewall can flow gas-liquid so that the ring inner surface will be took full advantage.

Packing Pall rings allows the tower to operate at an optimum efficiency and throughput, Consistent ratio of free and blocked passages, independent of orientation, Large surface area : volume ratio augments the rate of liquid film surface renewal to improve mass transfer.Packing Pall Ring Media can widely used in Adsorption, Steaming and Distilling performace, oil refinery, petrochemical industry, chemical industry and air pollution control etc., and also contracts anticorrosion engineering and environmental protection

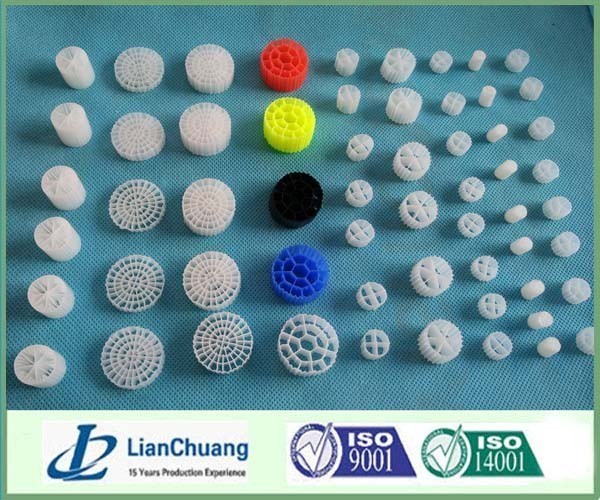

Pall ring's type:

Pall ring media can be classified at size,material.

Pall ring media's size could be 10mm, 16mm, 25mm, 38mm, 50mm, 76mm,90mm, 100mm etc.

Materiall could be ceramic,metal,plastic etc.

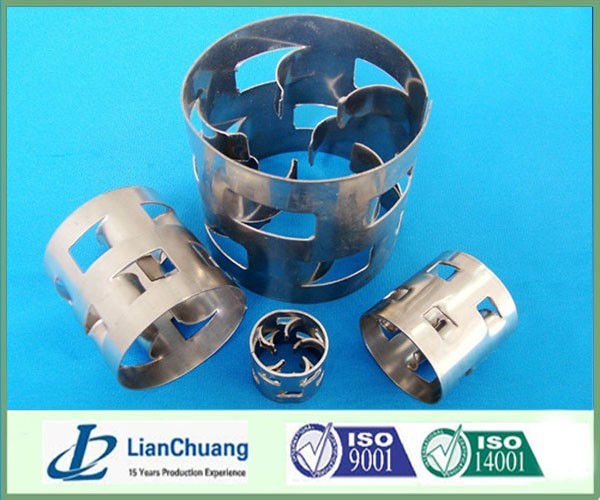

metal pall rings materials can be carbon steel, 1Cr18Ni9Ti, stainless 304, 304L, 410, 316, 316L,904L, alloy steel materiasl.if made from plastic it's material could be pp, pvc, pvdf, rpp,cpvc and so on.

Specification of Pall ring

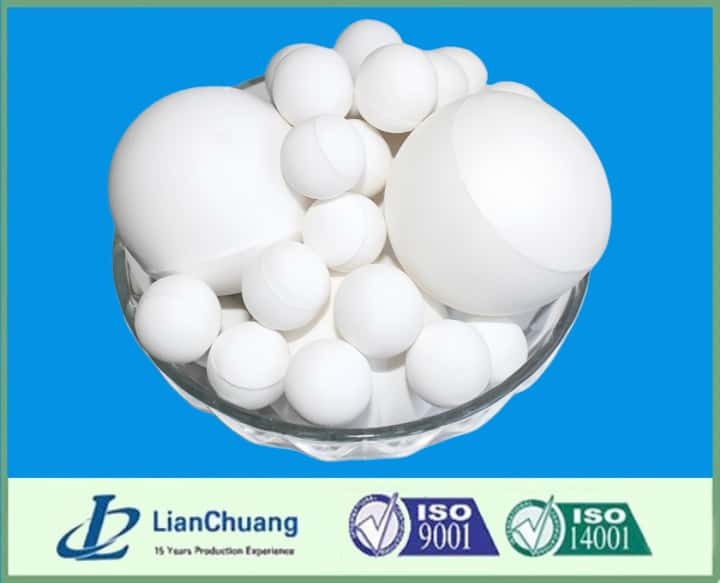

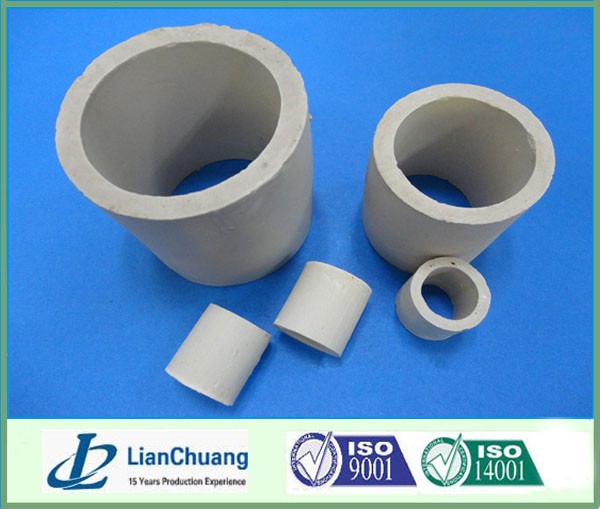

1.Ceramic Pall Ring has strong acid and alkali resistance, and high temperature resistance.

Ceramic Pall Ring Specification:

Size | DxHxT mm | Specific area m2m3 | Void volume m3m3 | Number pc./m3 | Bulk density kg/m3 | Dry packing factor m-1 |

1''(25mm) | 25x25x3 | 220 | 0.75 | 50000 | 600 | 565 |

1.5''(38mm) | 38x38x4 | 150 | 0.78 | 13400 | 540 | 356 |

2''(50mm) | 50x50x5 | 120 | 0.78 | 6400 | 555 | 252 |

3''(80mm) | 80x80x8 | 75 | 0.80 | 1950 | 520 | 146 |

2.Plastic Pall Ring has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on, and the application temperature in media ranges from 60°Cto 150°C. For these reasons it is widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

plastic pall ring Specification:

D*H*δ | Number per volume | Surface area | Void Volume | Dry packing factor |

mm | n/m3 | m2/m3 | % | m-1 |

16×16×1 | 180000 | 188 | 91.1 | 275 |

25×25×1.2 | 49000 | 175 | 90 | 239 |

38×38×1.4 | 13600 | 155 | 89 | 220 |

50×50×1.5 | 6300 | 93 | 90 | 127 |

76×76×2.6 | 1830 | 73.2 | 92 | 94 |

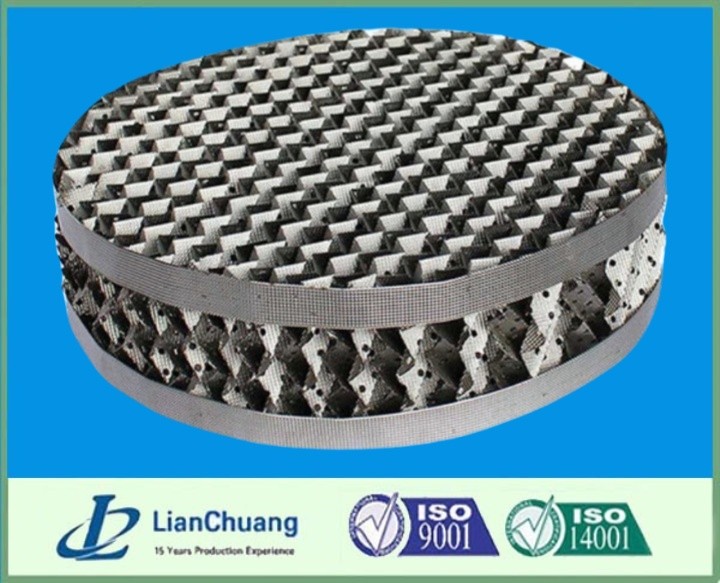

3.Metal Pall Ring is made of material like carbon steel, stainless steel or Alumina alloy, etc. The product has features such as thin wall, heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on.

metal pall ring's specification:

Size | Bulk density | Quantity | Specific surface area | Void volume |

mm | kg/m3 | n/m3 | m2/m3 | m3/m3 |

16*16*0.3 | 360 | 201000 | 346 | 95.5 |

25*25*0.4 | 302 | 51000 | 212 | 96.2 |

25*25*0.5 | 400 | 51000 | 216 | 95 |

25*25*0.6 | 461 | 51000 | 219 | 94.2 |

38*38*0.4 | 218 | 15000 | 143 | 97.2 |

38*38*0.5 | 262 | 15180 | 145 | 96.7 |

38*38*0.6 | 328 | 15000 | 146 | 95.9 |

50*50*0.5 | 194 | 6500 | 106 | 97.5 |

50*50*0.7 | 285 | 6500 | 108 | 96.4 |

50*50*0.9 | 365 | 6500 | 109 | 95.4 |

76*76*0.8 | 205 | 1830 | 69 | 97.4 |

90*90*1.0 | 229 | 1160 | 62 | 97.1 |

Pall ring's Characters

High void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, low specific gravity, and efficient mass transfer characterize this versatile component.

Extensively applied in the petroleum, chemical, alkali chloride, gas, and environmental protection industries, capable of withstanding temperatures up to 150 degrees Celsius.

Commonly utilized in the separation of toluene, ethylbenzene, desulfurization systems, and more. The Pall Ring's structural design enhances gas-liquid distribution, boosting efficiency by up to 50%. In comparison to the Raschig Ring, it boasts half the pressure drop.

Appication of pall ring

1. Absorption;

2. Scrubbing;

3. Stripping services;

4. All kinds of Seperation

5. Plastic packed columns;

6. Cooling Tower Packing

If need pall ring sample or price list, Welcome contact us for more detail.