Product Description

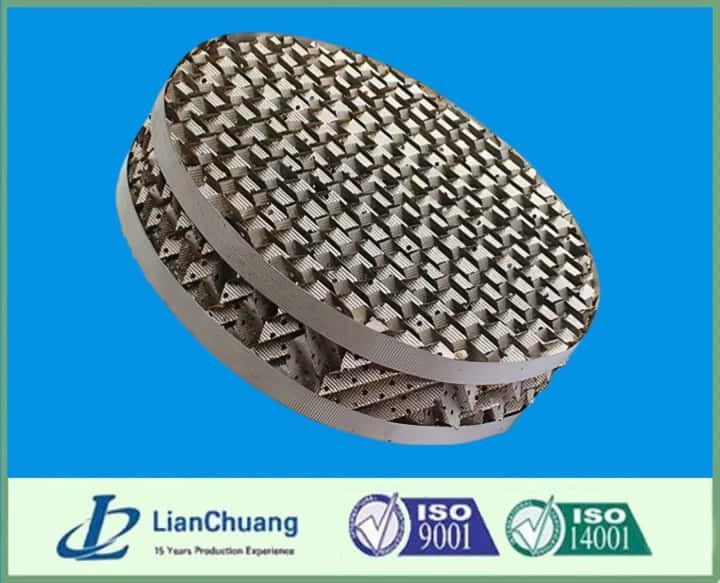

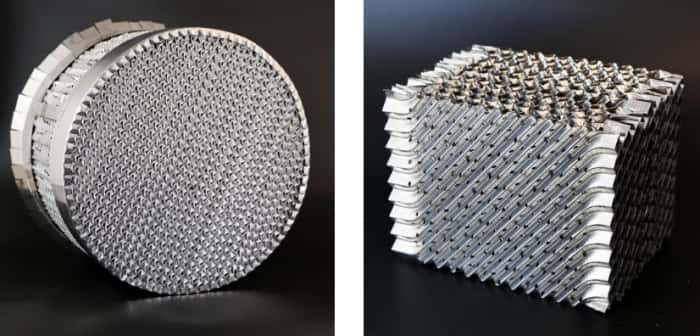

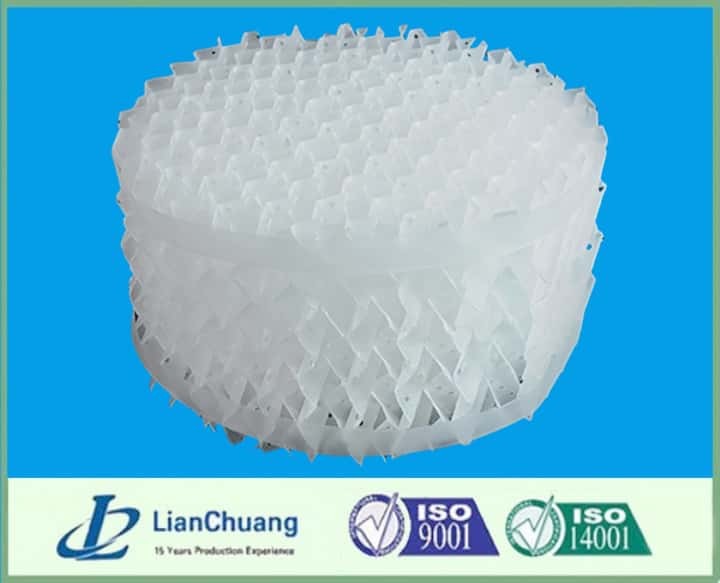

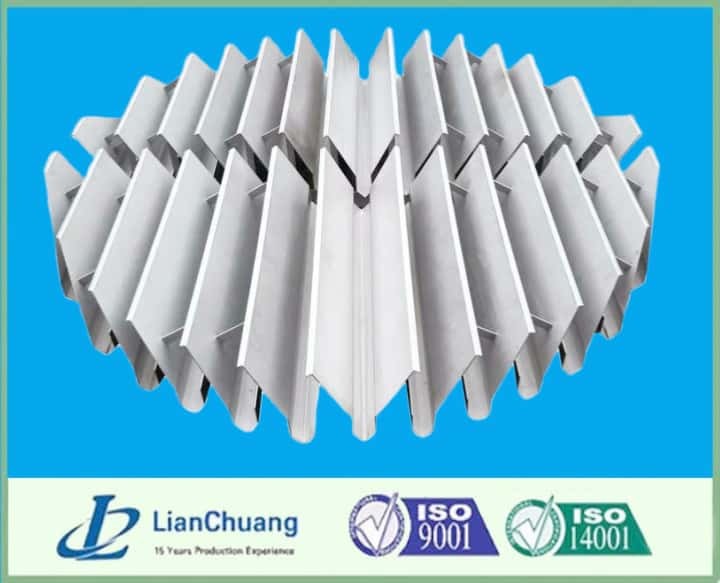

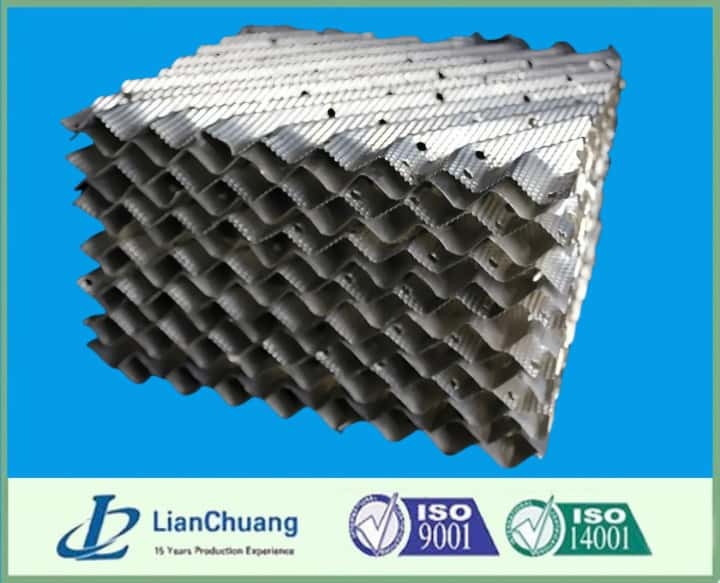

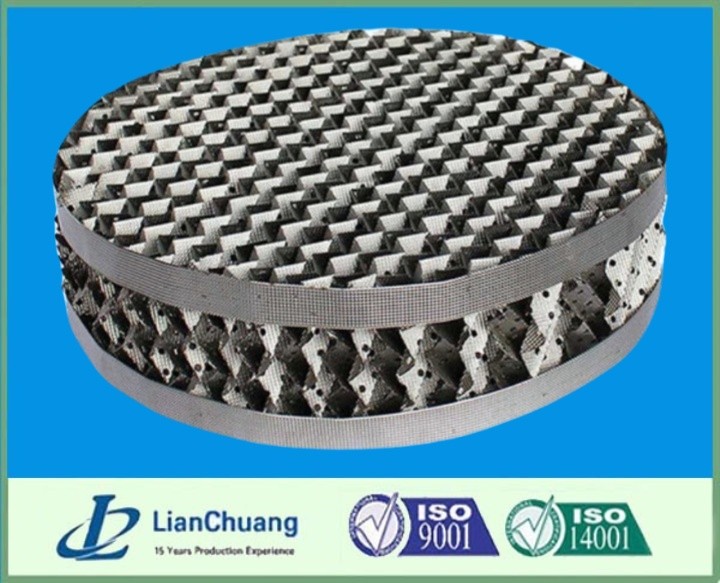

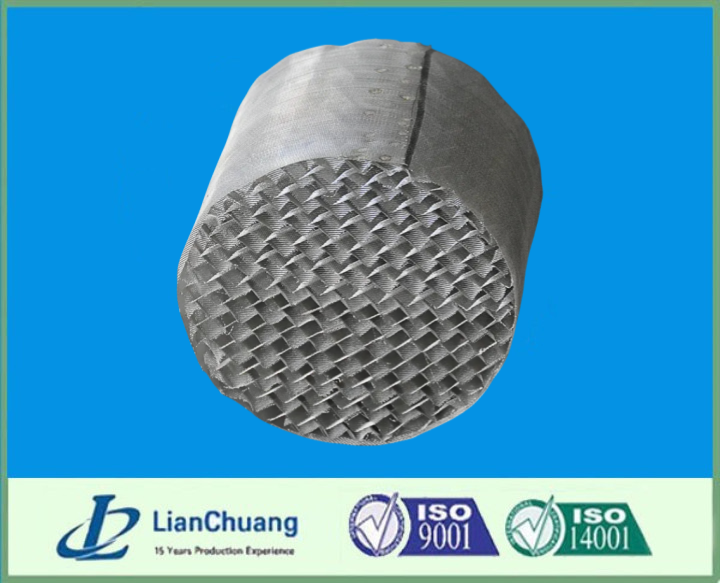

Metal perforated plate packings, such as the 250Y and 450Y types, are designed to optimize mass transfer in chemical processes. Made from corrugated metal sheets or wire mesh, these packings form a highly open, honeycomb-like structure with inclined flow channels. This design ensures a large surface area with minimal resistance to gas flow, making it ideal for applications that require efficient vapor and liquid interaction.

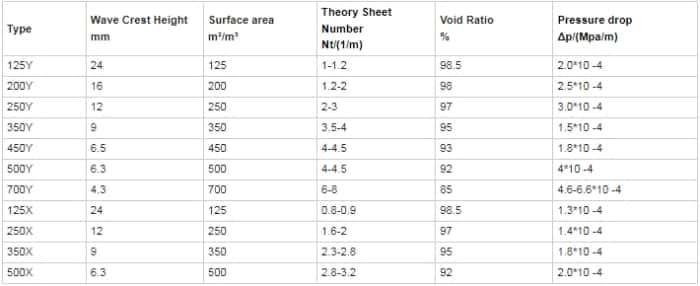

The primary advantage of metal perforated plate packings lies in their ability to provide high surface area and low pressure drop. These packings are highly efficient at enhancing liquid spreading, which is especially beneficial in low-pressure and low-irrigation rate processes. The surface area of the packing can vary significantly, ranging from 50 m²/m³ (for higher capacity but lower efficiency) to 750 m²/m³ (for higher efficiency but lower capacity). This versatility allows for a wide range of applications across industries.

Key Benefits

1. Low Resistance & High Efficiency: These packings offer minimal resistance to gas flow, making them suitable for operations with high flow rates and low pressure drops.

2. Versatile: Suitable for use in negative, normal, and pressurized environments.

3. Resistant to Fouling: Able to handle moderate fouling, maintaining performance with adequate liquid loading.

4. Improved Liquid Distribution: The unique corrugated structure enhances liquid distribution and mass transfer efficiency.

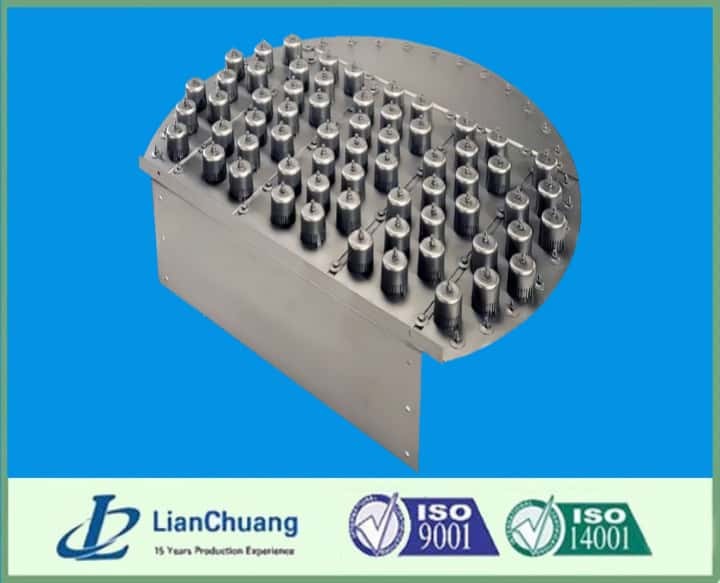

Installation Instructions

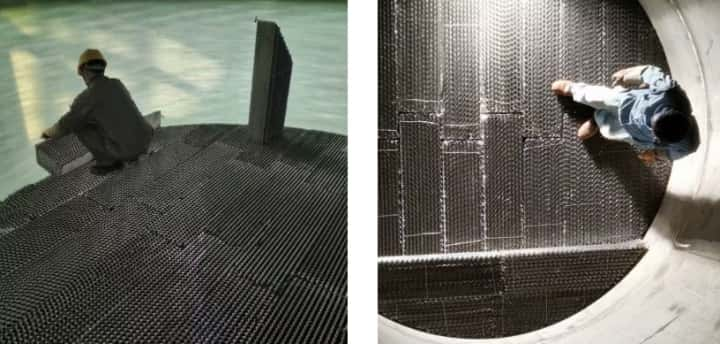

1. Refer to the tower equipment diagram and verify that the packing installation height is correct according to the specifications.

2. When installing, pour the packing from a certain height above the packing layer. Do not stand directly on the packing to avoid deformation or uneven density. Use wooden boards to evenly distribute the load.

3. Ensure that no foreign objects, such as packaging bags or debris, come into contact with the packing during installation, as they can interfere with performance.

4. Typically, fill the packing randomly, following the recommended procedures to ensure even distribution within the column.

5. After installation, check for any unevenness. If necessary, use a wooden strip to gently push the packing flat and ensure uniformity.

Specifications

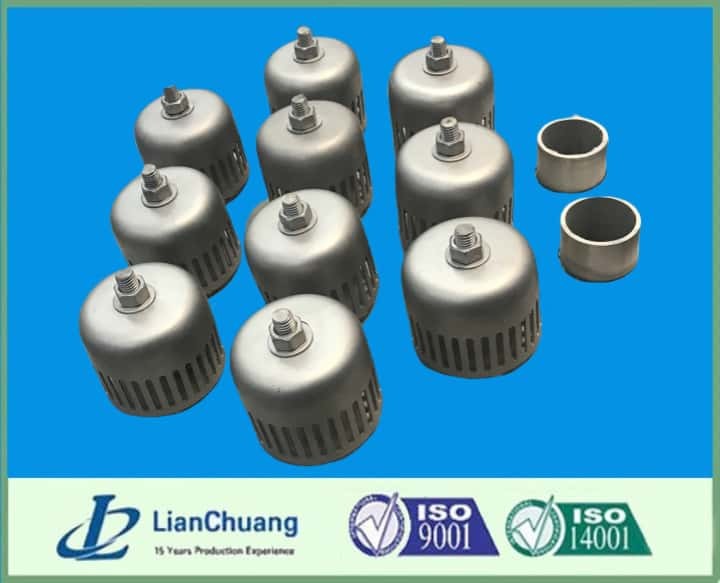

The metal perforated plate packings are available in various materials, including SS304, SS316L, carbon steel, aluminum alloy, and copper bronze. Custom materials can be provided upon request, allowing for tailored solutions to specific industry needs.

By offering a range of sizes, materials, and surface area configurations, metal perforated plate packings are a versatile and high-performance solution for improving mass transfer and operational efficiency in various industrial applications.

Applications

Metal perforated plate packings are widely used in chemical, petrochemical, oil refining, and natural gas industries. They are essential in unit operations such as rectification, absorption, and extraction. These packings can accommodate varying vapor and liquid flow rates and are suitable for both low and high-pressure environments. They are also resistant to fouling, making them durable in demanding operational conditions.