Product Description

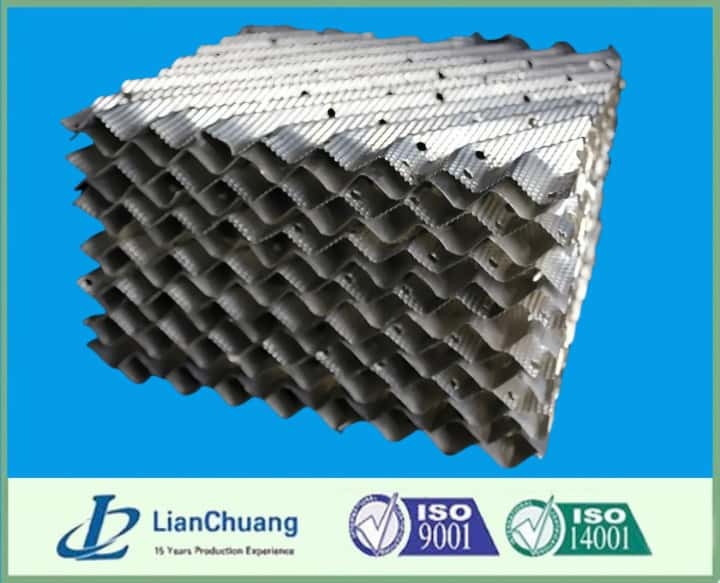

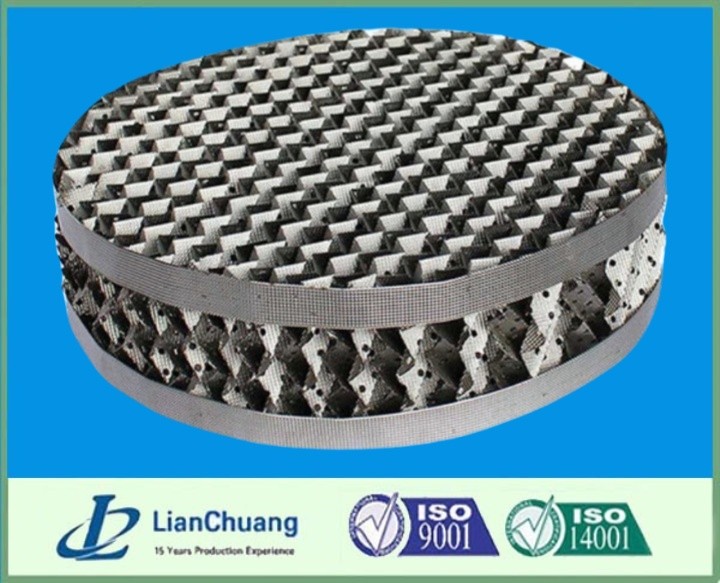

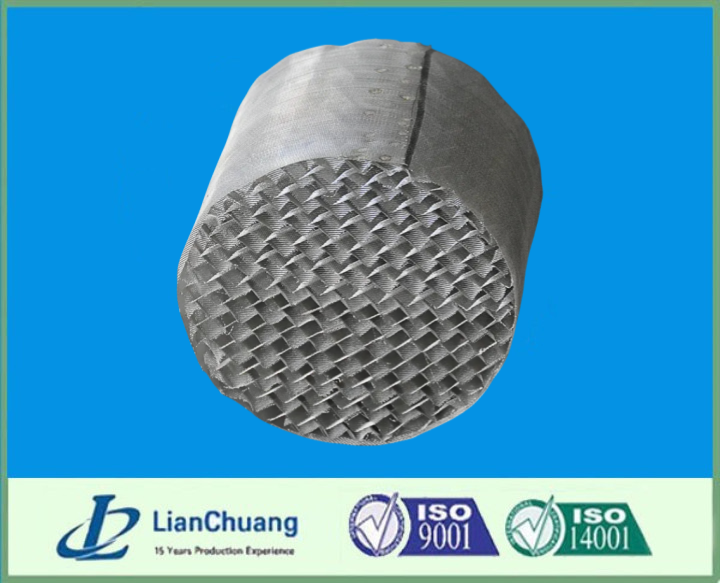

Metal plate-net corrugated packing is made by punching numerous diamond-shaped small holes into a thin metal plate, which is then drawn to the required specifications. This method simplifies the traditional process of wire drawing and mesh weaving.

Features:

Outstanding wetting ability.

Excellent separation efficiency.

Low resistance with uniform gas and liquid distribution.

High efficiency with large flow capacity and minimal magnifying effects.

Advantages:

1. High Capacity: New tower designs can reduce the diameter, and retrofitting older towers can significantly increase capacity.

2. Superior Separation Efficiency: Offers a larger specific surface area compared to random packings.

3. Low Pressure Drop: This results in significant energy savings by minimizing pressure losses.

4. Great Flexibility: The packing exhibits large flexibility with no significant scale effect.

5. Universal Application: Suitable for all tower diameters.

6. Strong Resistance to Corrosion: Especially resistant to acid, alkali, hydrogen sulfide (H2S), and naphthenic acid corrosion.

Applications:

This packing is commonly used in applications requiring the separation of heat-sensitive materials, as well as in atmospheric distillation, vacuum distillation, and absorption processes.