Product Description

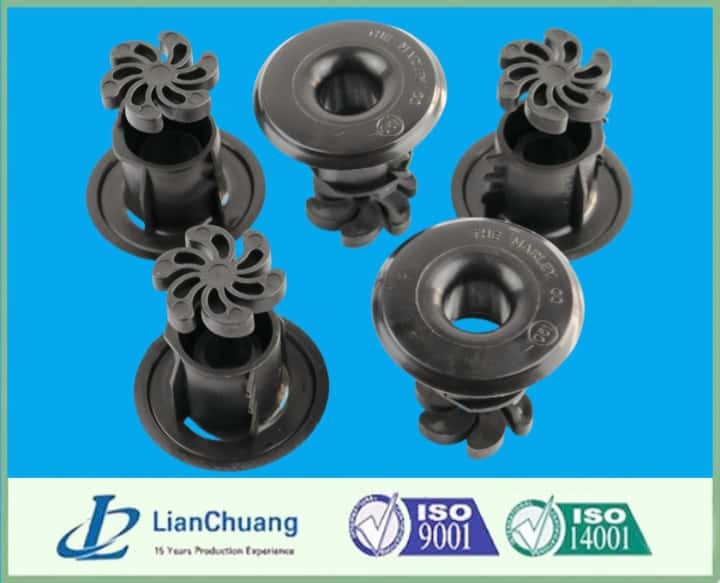

The Spiral Target Crossflow Nozzle is designed to replace the traditional ceramic metering orifice plates in the hot water distribution basins of crossflow cooling towers, while also eliminating the need for water distribution decks below the basins. The bottom part of the nozzle, commonly known as the “daisy,” features six blades that efficiently break up the water flow to ensure even distribution over the fill area.

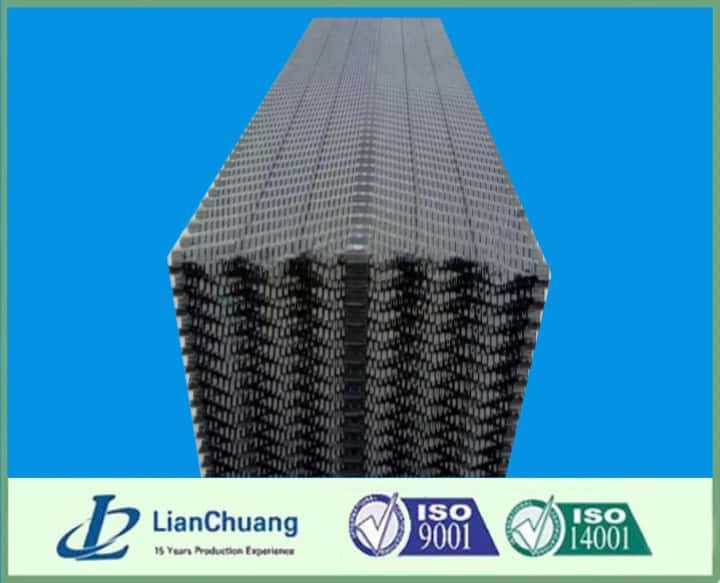

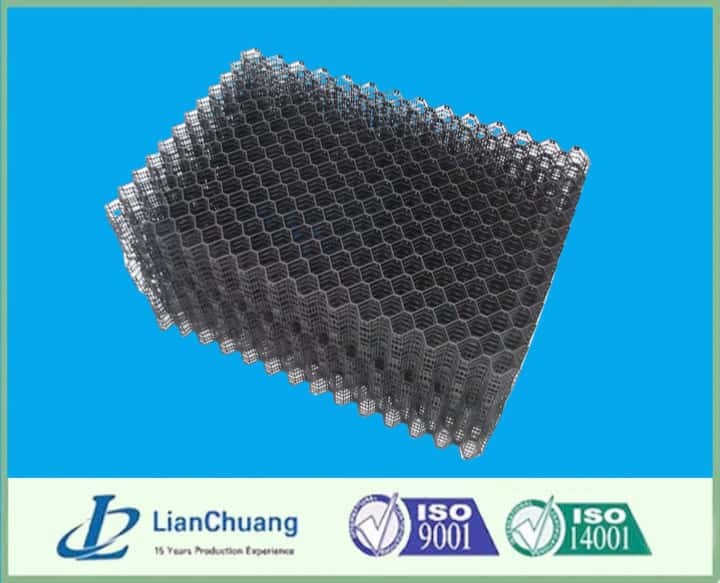

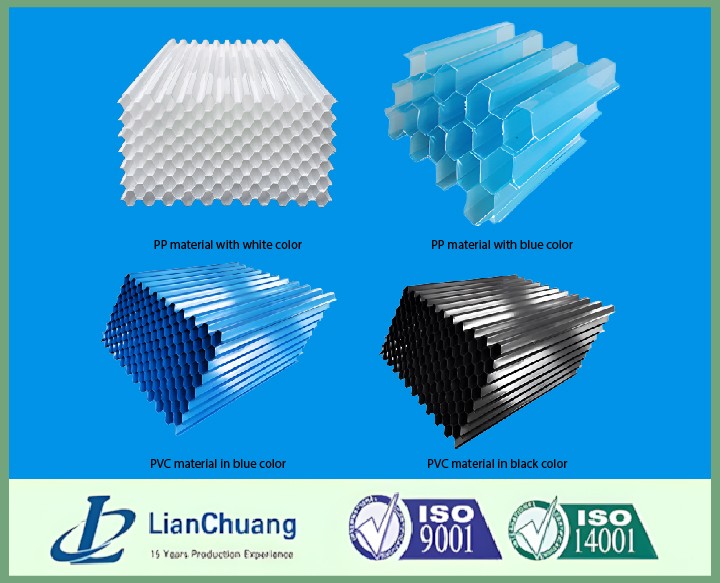

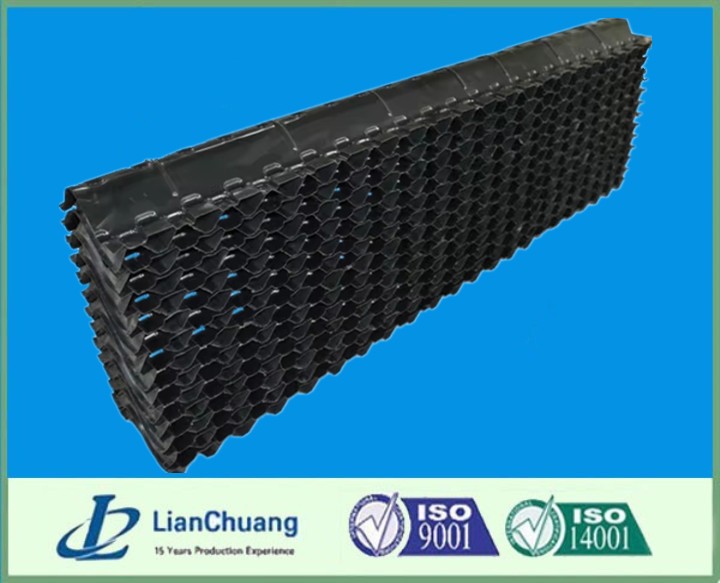

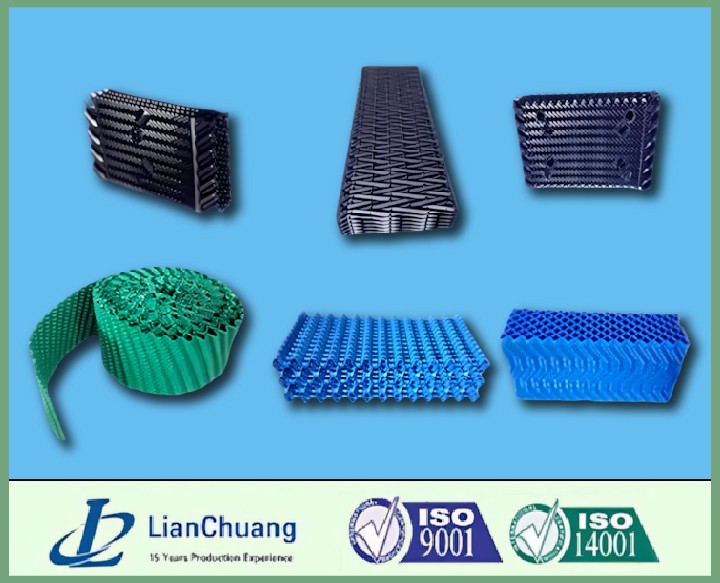

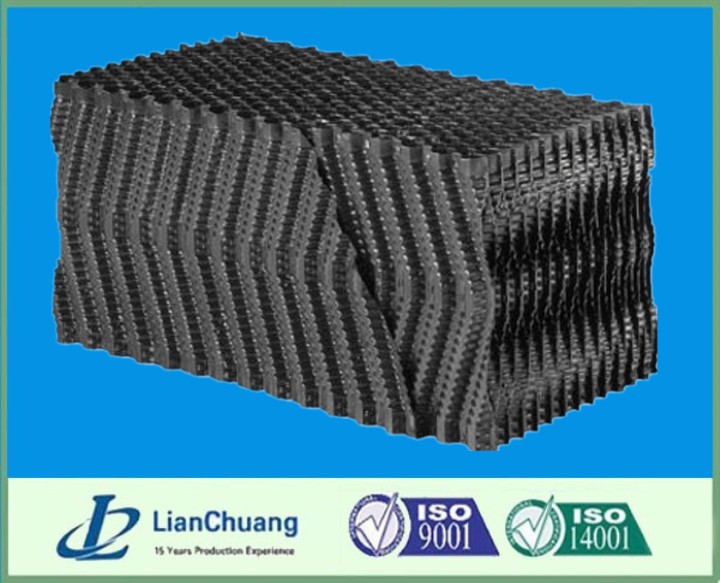

Structure and Material

The marley spiral target nozzle is made from injection-molded polypropylene and consists of two parts: the main body with an integrated target diffuser and a snap-on orifice cap. It measures 2.625″ from the bottom of the daisy to the top of the nozzle and is often called the Short-Stem nozzle. You can get it in nine different orifice sizes ranging from 3/8″ (coded 030) to 1″ (coded 066).

Where to Use

These small spiral target nozzles are ideal for wood, steel, and fiberglass cooling towers, especially when the basin support structure doesn't block water release. For all setups, the impact diffuser should be positioned at the perfect height above the fill to get maximum water coverage. This type of nozzle is standard for crossflow cooling towers and is super easy to install on cooling towers from different brands and ages.

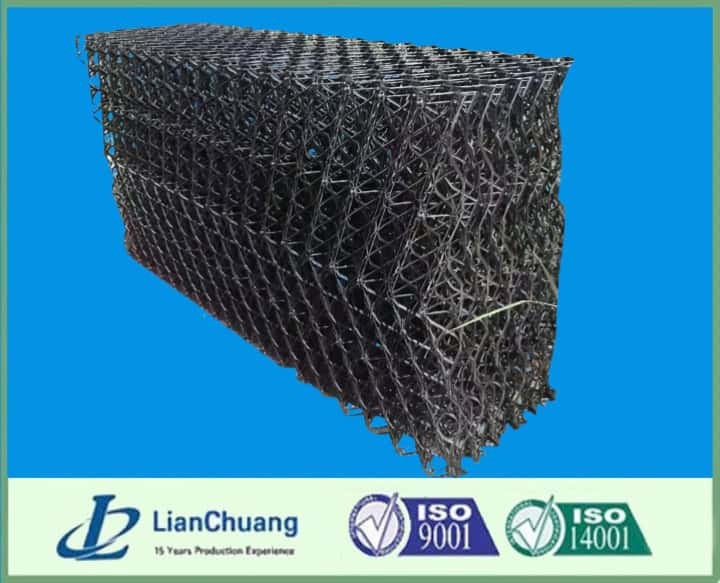

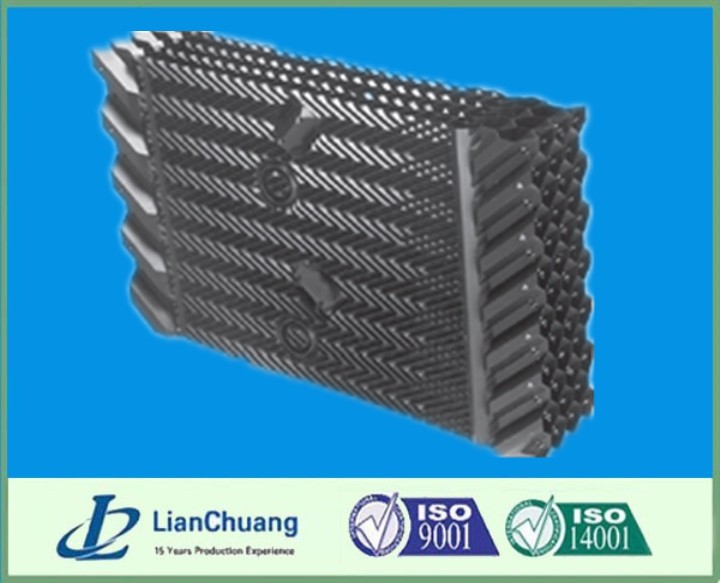

How Cooling Tower Nozzles Work

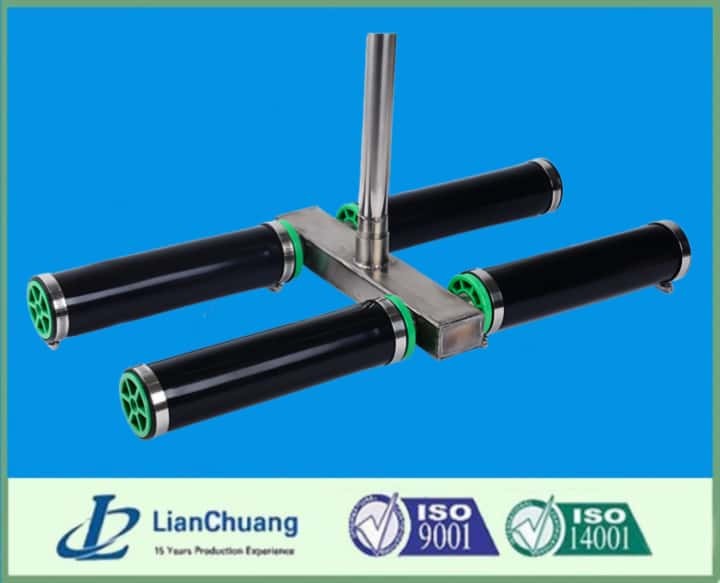

The working fluid flows inside coils, while spray water surrounds the outside. Heat from the water moves through the coil, and when the water meets the air, it turns into saturated steam. Fans at the top of the tower push the heat out, while the water is collected in the basin below and reused continuously.

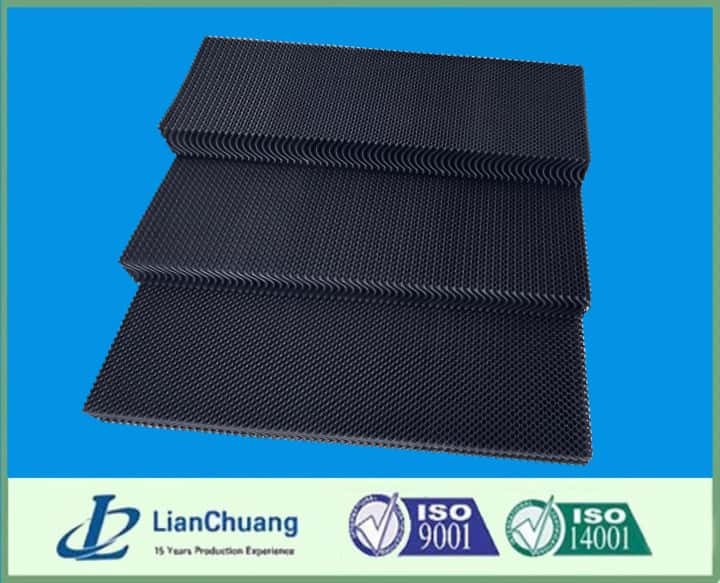

During circulation, the spray water cools down as it flows through PVC fill sheets and moves in the same direction as fresh air. The coils mainly transfer heat through sensible heat exchange. This method helps prevent scaling on the outside of the coils, making it perfect for handling high-temperature fluids (like 60°C) or when you need to cool fluids from high to low temps (like from 60°C to 35°C).

Cooling Tower Nozzle Specs

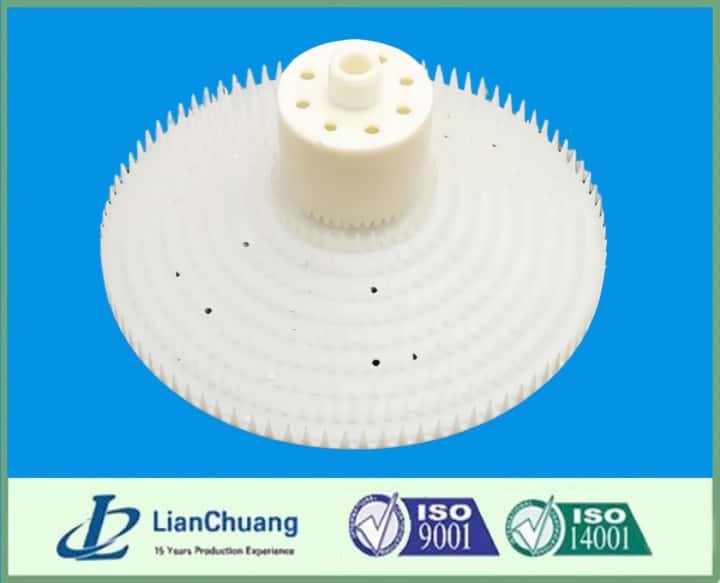

- Nozzle types include Type A, AA, and Pyramid nozzles, each with rubber gaskets for easy inspection and removal.

- XF nozzles are gravity-fed and can be checked or swapped out while the system is running.

- Adapter kits are available to mount 360° nozzles on other brands' coil products.

- Patented design works with pressurized or gravity feed systems, ensuring top heat performance.

- Large opening design helps prevent clogs and keeps the heat exchange surface fully wetted.

- Various sizes are available to handle different system flow rates.

- Optional orifice sizes range from 1/4″ to 1 1/8″ for accurate flow control.

Key Features

- The go-to standard in crossflow nozzle design.

- Available in three lengths to fit nearly any structure.

- Thirteen different orifice sizes for perfect performance tweaks.

- No moving parts to worry about.

- Wide range of water flow adjustments.

- Super easy to install.

- Great durability and resistance.

- High mechanical strength.

- Removable and replaceable basin parts.

- Uses gravity flow for full fill coverage.

- Made of a body (with integrated target diffuser) and a snap-in metering orifice.

- The base, called the daisy, has six blades to break up the water efficiently.

- Available in four different lengths to match your needs.

Applications

- Large industrial wood cooling towers

- Concrete cooling towers

- Fiberglass cooling towers

- Plating tanks

- Cleaning tanks

- Phosphating tanks

- E-coat tanks

- Fertilizer tanks

- Pulp tanks

- Sludge tanks

- Paint booths

- Anodizing tanks

- Cooling towers