Product Description

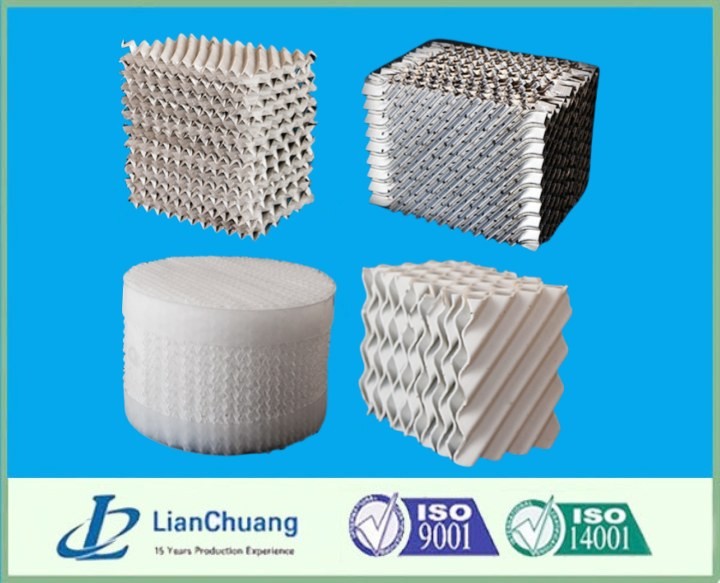

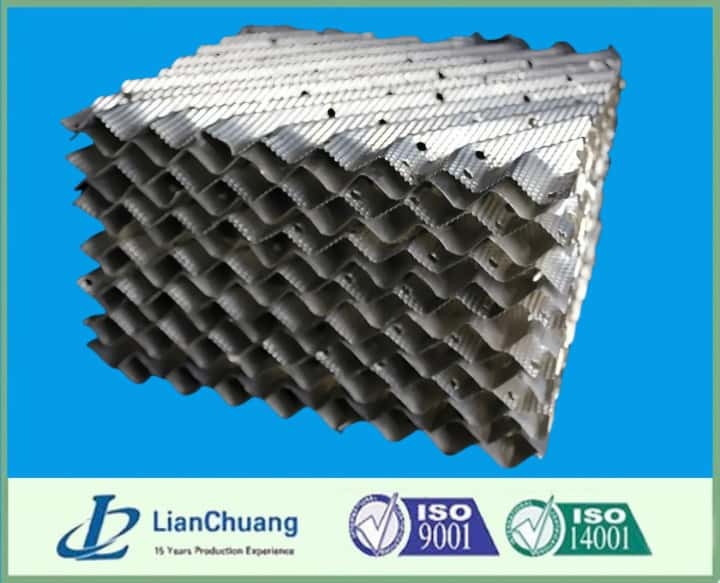

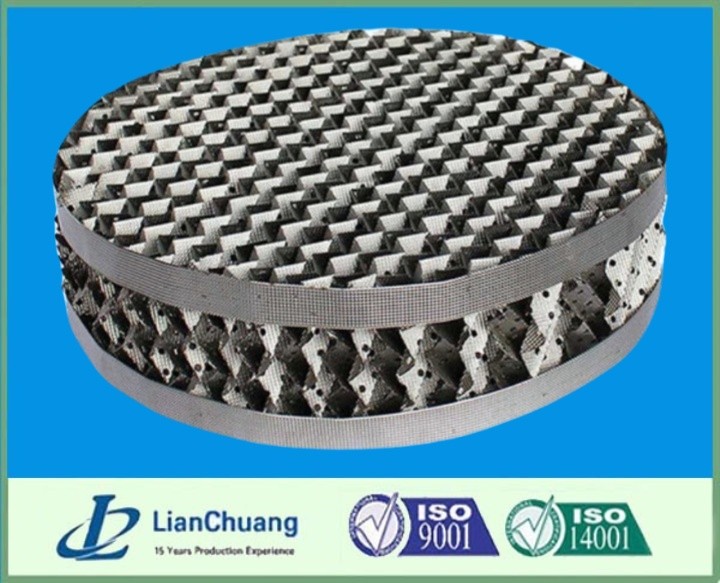

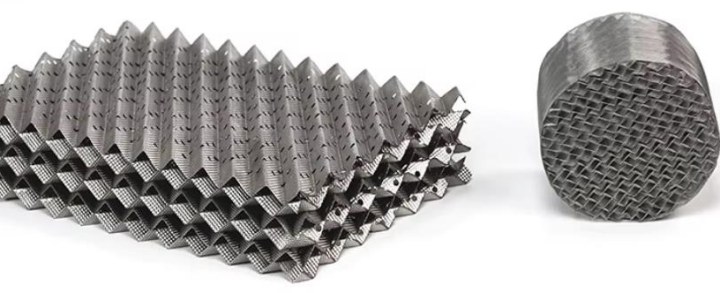

Stacked packing, also referred to as structured packing, is a meticulously designed material used in chemical processing to optimize mass transfer efficiency. It is particularly effective in processes requiring precision and consistency, making it a preferred choice in industries like pharmaceuticals, petrochemicals, and specialty chemical manufacturing.

stacked packing involves the use of regularly arranged elements in a column. Unlike random packing, stacked packing is highly organized, ensuring uniform fluid distribution and maximizing the interaction between gas and liquid phases. These materials are often manufactured from durable materials such as metals, ceramics, or advanced plastics to handle demanding industrial environments.

How Stacked Packing Works

The geometric structure of stacked packing allows liquid to spread into a thin film over the surface, maximizing exposure to gas flow. This optimized interaction results in superior separation efficiency and reduces energy loss. The structure also minimizes dead zones and ensures even distribution of fluids, which is critical in achieving consistent results in mass transfer processes.

Material of Stacked Packing

Stacked packing is commonly manufactured from three types of materials: metal, ceramic, and plastic. Each material offers distinct properties, catering to different industrial requirements and environmental conditions. By selecting the appropriate material, industries can achieve optimal performance, efficiency, and longevity in their mass transfer and separation processes.

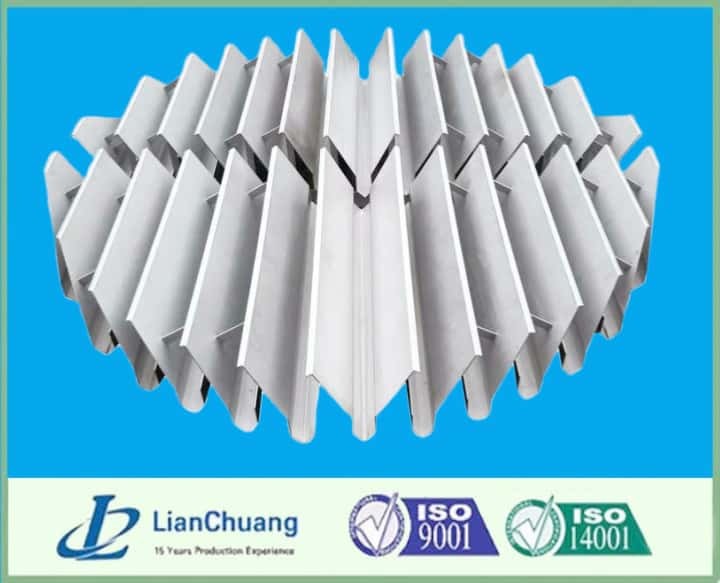

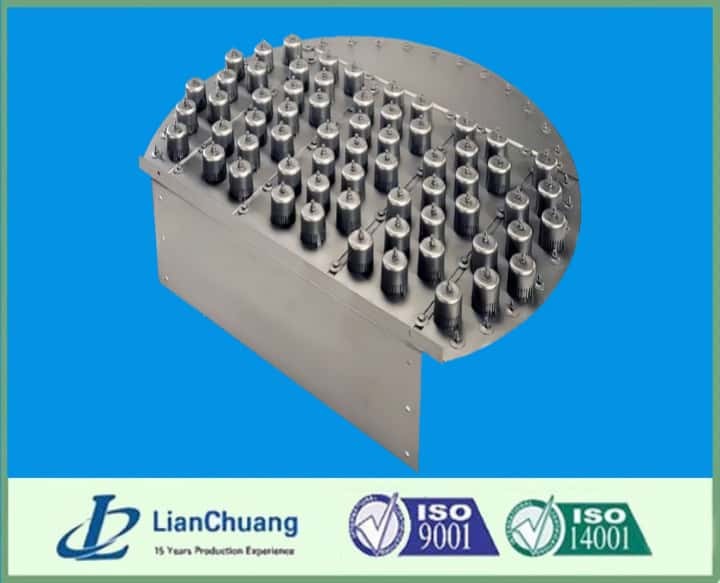

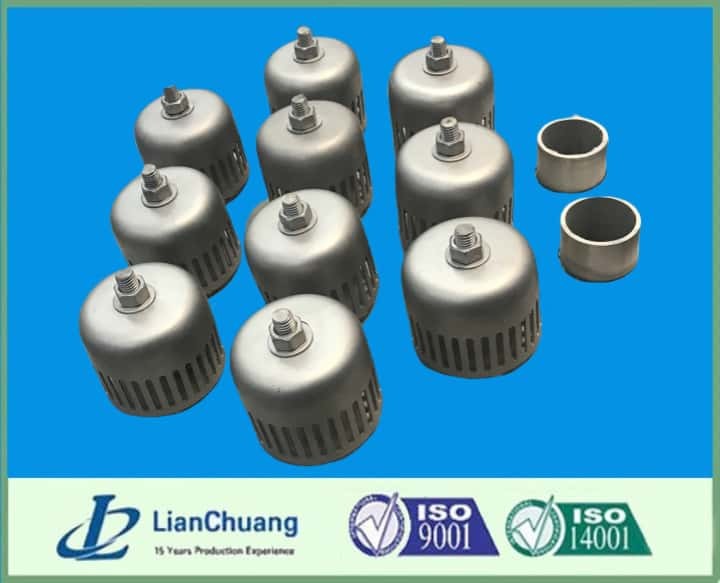

Metal ( carbon steel, 304, 321, 316L stainless steel )

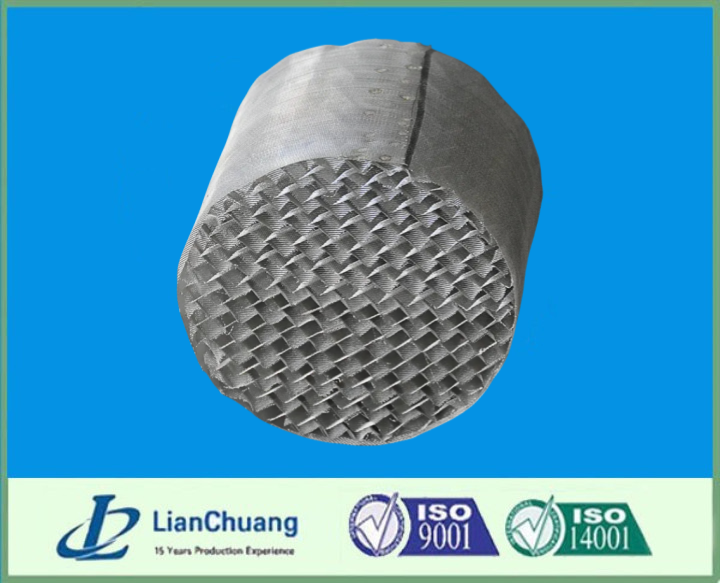

Metal stacked packing is typically made from stainless steel or corrosion-resistant alloys. Known for its strength and durability, it is suitable for high-temperature and high-pressure applications. Metal packing is widely used in industries such as petrochemical refining, where the environment is often corrosive and demanding. Its thin-wall construction also enhances surface area, improving mass transfer efficiency.

Ceramic

Ceramic stacked packing offers excellent resistance to chemicals and thermal shock. It is ideal for processes involving highly corrosive substances, such as acids and alkalis, and can withstand extremely high temperatures. This makes ceramic packing a popular choice in industries like pharmaceuticals and chemical manufacturing, where metal contamination must be avoided.

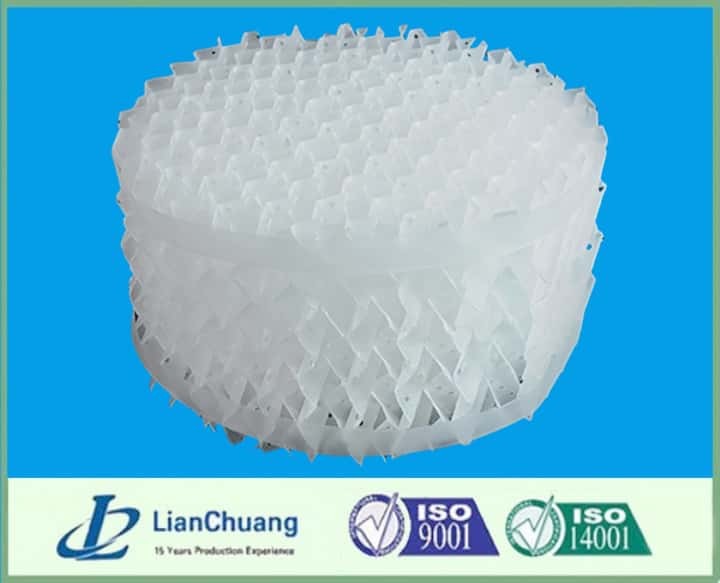

Plastic ( pp hdpe pvdf pvc rpp )

Plastic stacked packing, made from polymers such as polypropylene or polyethylene, is lightweight and cost-effective. It is highly resistant to corrosion and physical wear, making it suitable for moderate temperature and pressure applications. Commonly used in water treatment and environmental processes, plastic packing offers a practical solution for industries seeking durability at a lower cost.

Advantages of Stacked Packing

- Superior Efficiency: The structured design maximizes surface area, enhancing the interaction between phases for improved performance.

- Energy Savings: Reduced pressure drop minimizes energy consumption, leading to lower operational costs.

- Predictable Behavior: The systematic arrangement enables precise modeling, simplifying process control and optimization.

- Durability: Made from corrosion-resistant materials, stacked packing withstands harsh environments and ensures long-term reliability.

- Customizability: Packing elements can be tailored to specific process requirements, making them versatile across various industries.

Applications of Stacked Packing

- High-Purity Distillation: Critical in the pharmaceutical and petrochemical industries where precision is paramount.

- Energy-Efficient Processes: Ideal for industries focusing on sustainability and energy conservation.

- Chemical Reactors: Enhances the efficiency of phase contact in reactors, improving reaction outcomes.

- Air Separation: Used in cryogenic distillation processes to separate oxygen, nitrogen, and other gases with high precision.

Comparison: Stacked Packing vs. Random Packing

While stacked packing offers high efficiency and reliability, random packing remains a practical choice for less demanding applications. Here’s a detailed comparison:

| Feature | Stacked Packing | Random Packing |

|---|---|---|

| Arrangement | Systematically structured | Irregular and loosely arranged |

| Mass Transfer Efficiency | Higher | Moderate |

| Pressure Drop | Lower | Higher |

| Installation | Time-consuming and complex | Quick and easy |

| Cost | Higher initial investment | Lower initial cost |

| Customization | Highly customizable | Limited customization options |

| Applications | High-precision processes | General-purpose operations |

Conclusion

Stacked packing is the pinnacle of efficiency and precision in industrial applications. Its structured design provides unparalleled performance in mass transfer processes, making it essential for industries requiring consistent and energy-efficient operations. While random packing is suitable for cost-sensitive and less critical applications, stacked packing offers superior long-term value and reliability.

As technology advances, stacked packing continues to evolve, incorporating new materials and designs to meet the growing demand for sustainable and efficient industrial processes. For industries aiming to optimize performance, stacked packing remains an indispensable solution