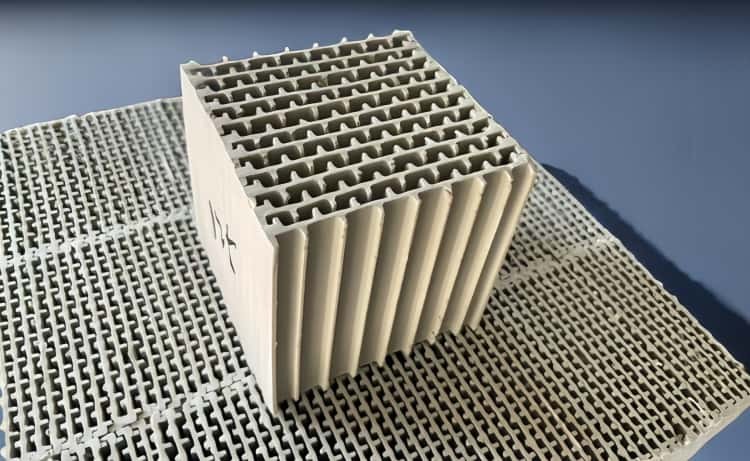

multi-layer ceramic media (MLM) is a high-performance structured packing widely used in Volatile Organic Compound (VOC) emission control equipment—Regenerative Thermal Oxidation (RTO) systems. MLM-200(4″, 12″) for Regenerative Thermal Oxidizer Heat Recovery Mediais made of ceramic plates with a unique prong design on the surface. This design enhances airflow distribution and thermal efficiency while significantly reducing VOC emissions, ensuring compliance with environmental standards.

2. Key Features

1. High Thermal Conductivity: Made from ceramic materials, MLM retains excellent thermal stability at high temperatures, enabling efficient heat transfer. This helps reduce energy consumption and improves system performance.

2. Optimized Airflow Distribution: The prong design of MLM ensures uniform airflow distribution throughout the packing layer, eliminating uneven flow that could otherwise impair reactor efficiency and performance.

3. Exceptional Corrosion Resistance & Durability: MLM is constructed from corrosion-resistant ceramic materials, ensuring superior resistance to high temperatures, humidity, and acidic or alkaline gases. This makes it ideal for long-term, stable operation in harsh environments.

4. VOC Emission Reduction: The multi-layer structure of MLM effectively reduces VOC emissions within the RTO system and enhances the efficiency of the thermal oxidation process, helping meet strict environmental regulations.

5. Lightweight and Easy to Install: The multi-layer ceramic plate design is compact and efficient, facilitating easy installation and maintenance, thus reducing downtime and operational complexity.

6. Wide Range of Applications: MLM is used in various industries, including chemicals, petrochemicals, pharmaceuticals, and other VOC emission control applications. It is particularly effective for handling high-concentration and complex gas emissions.

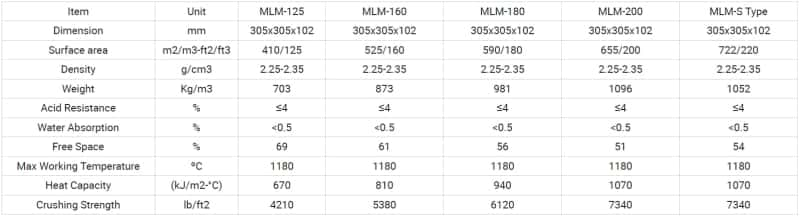

3. Technical Specifications

1. Material: High-performance ceramic

2. Operating Temperature: Can withstand temperatures up to 1100°C

3. Thermal Conductivity: Low, ensuring efficient heat exchange

4. Airflow Distribution: Optimized design for superior reaction efficiency

5. Corrosion Resistance: Resistant to acidic and alkaline corrosion, suitable for various gas environments

6. Structure: Multi-layer ceramic plates with prong design

4. Applications

1. Regenerative Thermal Oxidation (RTO) Systems

2. VOC Gas Emission Control

3. Chemical, Petrochemical, Pharmaceutical Industries

4. Wastewater Treatment and Other Environmental Protection Equipment

5. Conclusion

Multi-layer Ceramic Media (MLM) is an efficient VOC treatment packing that offers excellent thermal conductivity, corrosion resistance, and optimized airflow distribution. As an ideal choice for RTO systems, MLM enhances energy efficiency, reaction effectiveness, and supports companies in meeting environmental protection standards.

Our company also offers customized production options to meet the specific needs of our clients. Please feel free to contact us for more details or technical consultations.