Product Description

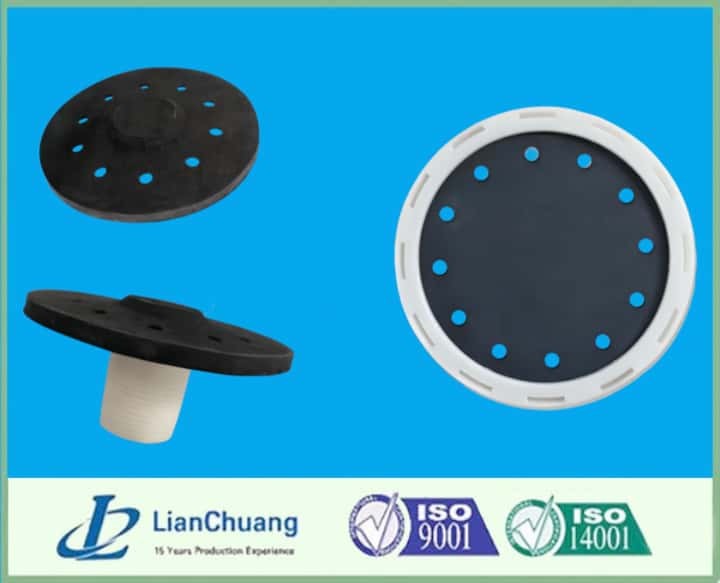

Mbbr media is one kind of new bioactive carrier as a house for attached growth bacteria in mbbr process. mbbr media also called kaldness media, it works as carrier for the growth and attachment of microorganisms are directly put into the mbbr system, the waste water go through the suspended carriers in MBBR reactor,kaldness media adopt scientific formula and blend some micro-elements in the high polymer material, which microorganisms attach themselves to submerged moving biofilm carrier, forming a biofilm. Air is transferred into the water, mixing the media and water and providing oxygen to the bacteria. The mbbr media biofilm absorbs, oxidizes and reduces organic and inorganic material thus providing treatment.

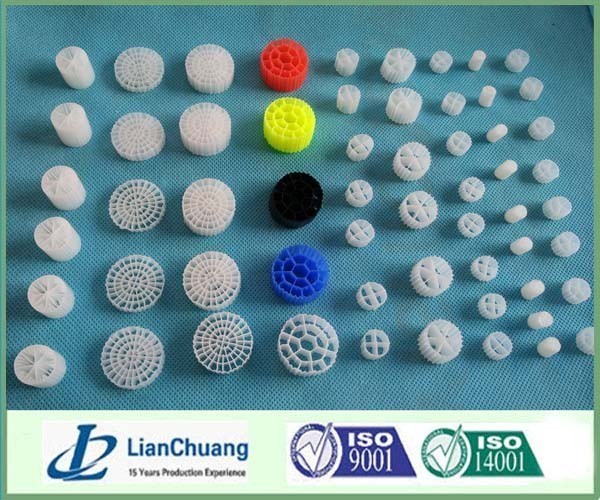

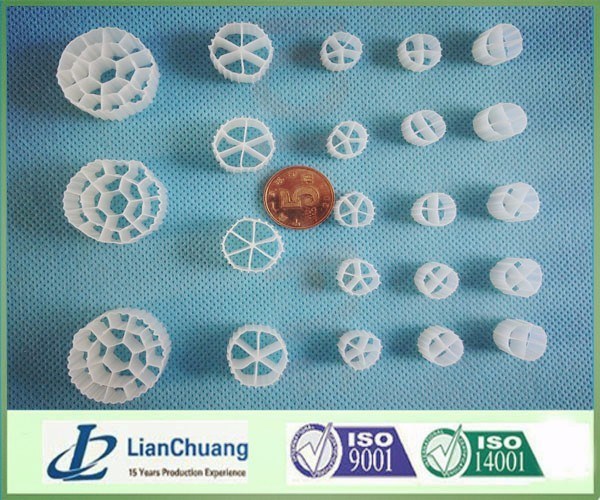

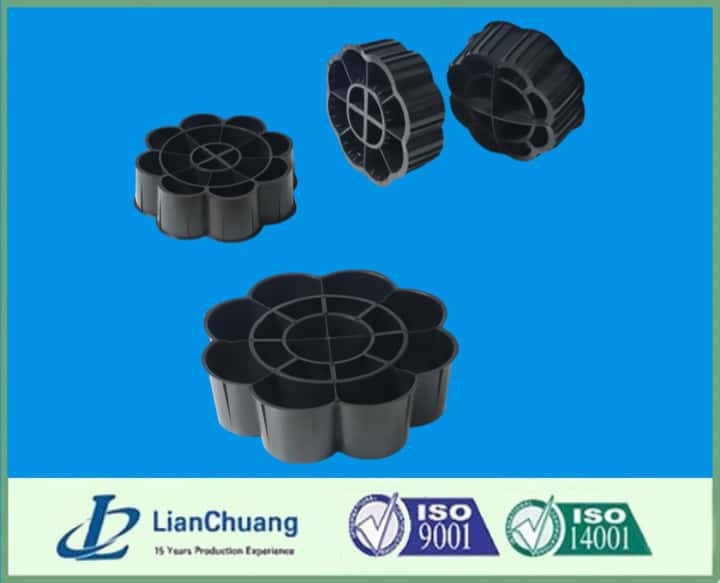

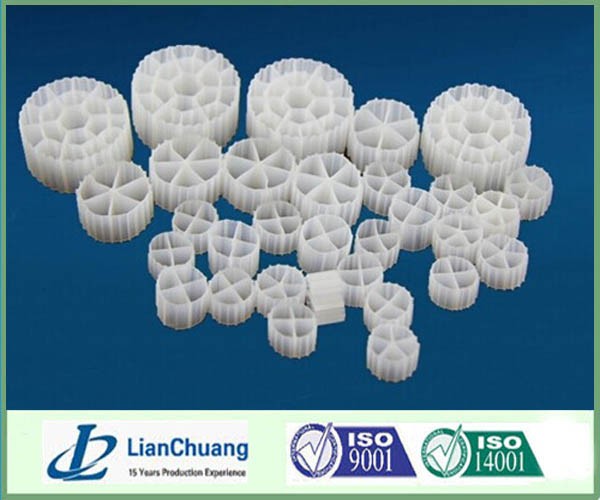

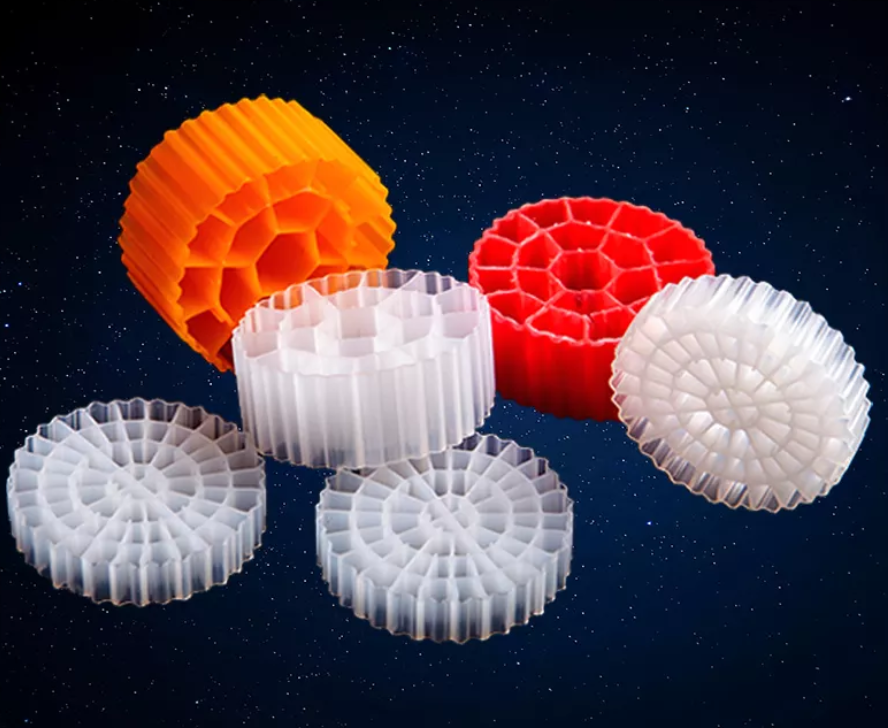

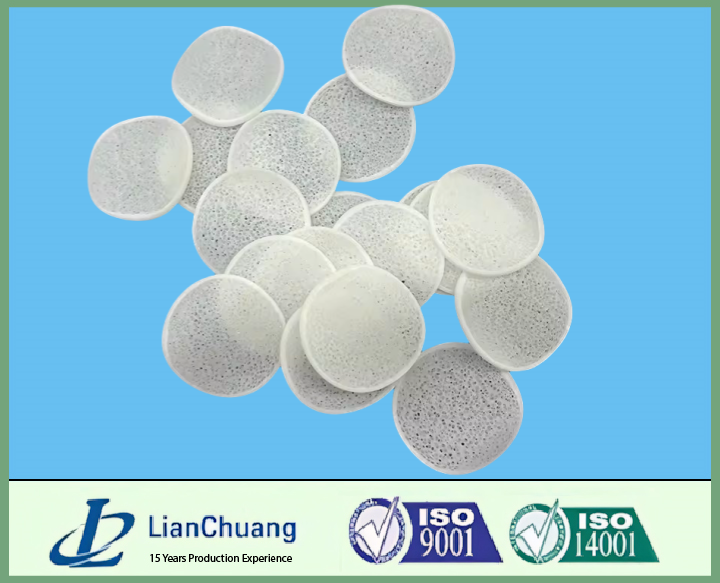

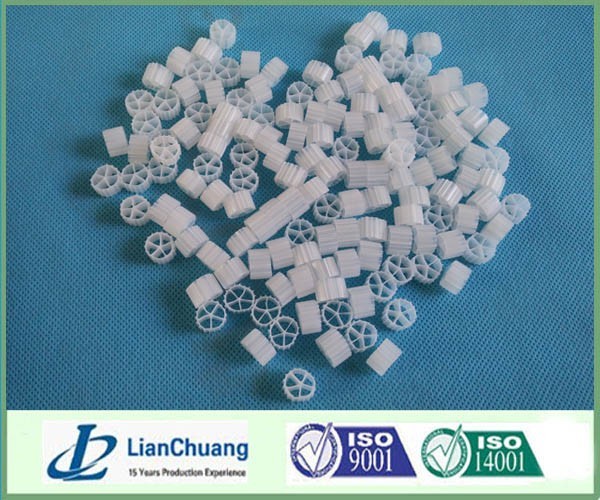

Our factory's kaldness mbbr media possess advantages of good hydrophilicity , high biological activity, quick film formation, easy to multiply, difficult falling off, large specific surface area and high biomass, appropriate specific gravity and good fluidization effect.We used hdpe material intead of common pe material, compare with common PE material, which can prolong its service life, and can expose in sunlight for higher temperature.And our material already got the certificate of FDA certificate. We also have done many innovations for biological filter media in machine and production process to improve the quality of the bio flter media,to keep its roundness,length,density more uniform and unified.We has aslo developed several types of kaldness media carriers with different shape, size and surface area. This gives us the flexibility to use the best suitable carrier depending on wastewater characteristics, pretreatment, discharge standards and available volumes.

Features of MBBR Media:

Scientific formula, rapid forming biofilm

Large specific surface area, attachment more microorganism

Easy fluidization, low energy consumption

Flexible dosing ratio, high load capacity

MBBR Media Technical Data:

Model |

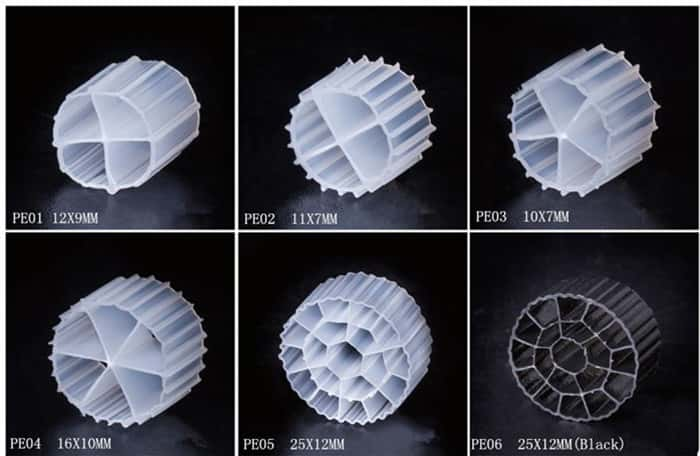

| PE01 | PE02 | PE03 | PE04 | PE05 | PE06 |

Spec | mm | 12X9mm | 11X7mm | 10X7mm | 16X10mm | 25X12 | 25X12 |

HoleNumbers | pcs | 4 | 4 | 5 | 6 | 19 | 19 |

Efficentsurface | m2/m3 | >800 | >900 | >1000 | >800 | >500 | >500 |

Density | g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 |

Packingnumbers | pcs/m3 | >630000 | >830000 | >850000 | >260000 | >97000 | >97000 |

Porosity | % | >85 | >85 | >85 | >85 | >90 | >90 |

Dosingratio | % | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 | 15-65 |

Membrane-formingtime | days | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 |

Nitrificationefficiency | gNH3-N/M3.d | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 |

BOD5oxidationefficiency | gBOD5/M3.d | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 |

CODoxidationefficiency | gCOD5/M3.d | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 |

Applicabletemperature | ℃ | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

Lifespan | year | >15 | >15 | >15 | >15 | >15 | >15 |

Model |

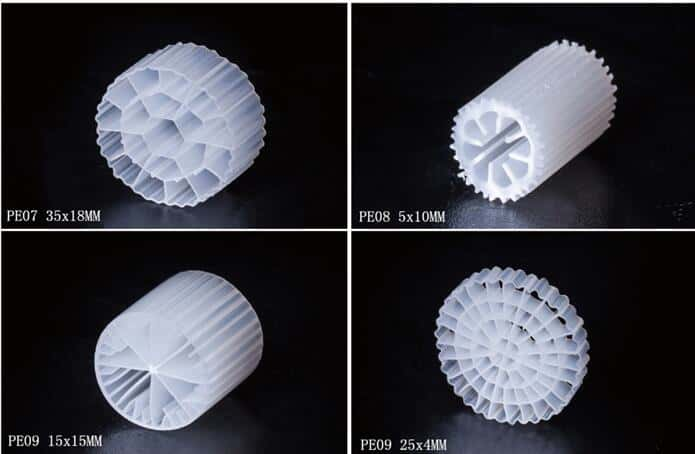

| PE07 | PE08 | PE09 | PE10 |

Spec | mm | 35X18mm | 5X10mm | 15X15mm | 25X4mm |

HoleNumbers | pcs | 19 | 7 | 40 | 64 |

Efficentsurface | m2/m3 | >350 | >3500 | >900 | >1200 |

Density | g/cm3 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 |

Packingnumbers | pcs/m3 | >33000 | >2000000 | >230000 | >210000 |

Porosity | % | >92 | >80 | >85 | >85 |

Dosingratio | % | 15-50 | 15-70 | 15-65 | 15-65 |

Membrane-formingtime | days | 3-15 | 3-15 | 3-15 | 3-15 |

Nitrificationefficiency | gNH3-N/M3.d | 300-800 | 500-1400 | 500-1400 | 500-1400 |

BOD5oxidationefficiency | gBOD5/M3.d | 1000-5000 | 2500-15000 | 2500-15000 | 2500-20000 |

CODoxidationefficiency | gCOD5/M3.d | 1000-10000 | 2500-20000 | 2500-20000 | 2500-25000 |

Applicabletemperature | ℃ | 5-60 | 5-60 | 5-60 | 5-60 |

Lifespan | year | >15 | >15 | >15 | >15 |

Advamtages of Kaldness Media:

1. Rapid forming biofilm and easy to multiply.

Adding various trace elements in the carriers and special processing technology, improve its hydrophilic performance, acceleration microorganisms attachment on the surface of the carriers, rapid growth and multiply , accelerate forming biofilm, in different water quality condition, biofilm formation has the schedule difference, general need 3-15 days.

2. High efficient decarburization, dephosphorization, ammonia nitrogen removal capacity.

Kaldness Media Carrier provide a excellent environment conducive to all kinds of microorganism growth and multiply. Due to the diversity of microbial populations and nitrifying bacteria massive growth and reproduction rapidly to dissolve organics and ammonia removal in the water.

3. Excellent resistance to shock loading capability.

Efficient removal of organic matter processing capacity, compared with other traditional ways to improve 2-5 times. High concentration of biomass and cSversity of microbial population, strong capability of resisting shock load, can be applied in the treatment of organic sewage with every kind of feed-water qualities, to ensure the stability of the effluent quality.

4. Flexible engineering applications.

According to the water quality and specific process, adding different amounts of mbbr media into the aerobic tank, anaerobictank and anoxic tank, can easily obtain satisfactory treatment effect.

5. Simple operation and maintenance, low energy consumption.

Without support, directly put carrier in the pool, easy to fluidity, saves energy consumption. By bio-film decomposing technology, saving sludge retunri process, avoiding sludge expansion, sludge floating and sludge loss, to make daily operation and management more convenient.

6. Longer media service life.

Through adding appropriate amount of anti-aging agent, anti UV agent, toughening agent and special process modified, to make it wear resistant, anti sun .strong toughness, not easy to aging and brittle fracture, the service life of more than 10 years.

7. Saving space, High efficiency denitrification and dephosphorization.

Under the same processing capacity and treatment effect, saving space reaches 2-3 times. Because of the super nitrification ability of biofilm, the ammonia nitrogen can be completely converted to nitrate nitrogen in water. Mbbr media enables denitrification to achieve the maximum effect, to make the nitrogen removal more thorough. At the same time, the huge phosphorus gathering bacteria in the biofilm can completely absorb phosphate substances in water, and through the shedding of biofilm into the sedimentation tank and finaly be discharged system as residual sludge, the effect of phosphorus removal is more obvious.

Beneits of MBBR Media:

1. Very good effluent quality.

2. Low capital cost.

3.Simple, robust design.

4.Energy efficient.

5.Ease of installation and operation.

6. Capacity of existing works can be quickly and easily increased.

7. Low operating cost.

8.Small footprint for new works.

9. Upgrade of existing works-simultaneously increase capacity and improve effluent quality

Kaldness MBBR Media Appliaction:

1. All types of industrial and domestic wastewater.

2. Both organic as nitrogen removal.

3. New plants or system upgrades.

4. Aquaculture degrade ammonia nitrogen, water purification.

5. Biological filler biological deodorization tower

6. New sewage treatment project of MBBR and BAF process.

Our factory can supply different types of mbbr medias with different shape, size and surface area. Customers can be flexible to choose the best suitable carrier depenclng on wastewater characteristics, wastewater treatment process, wastewater discharge standards and available volumes.Welcome contact us for more detail.