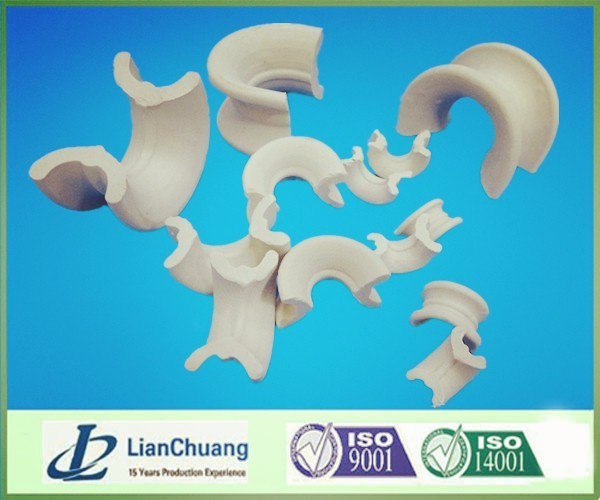

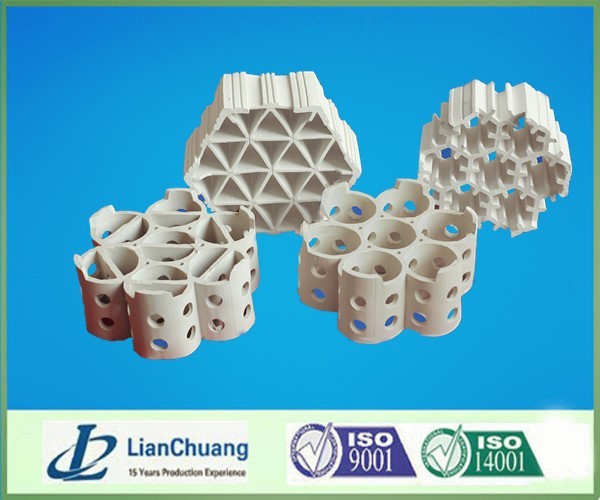

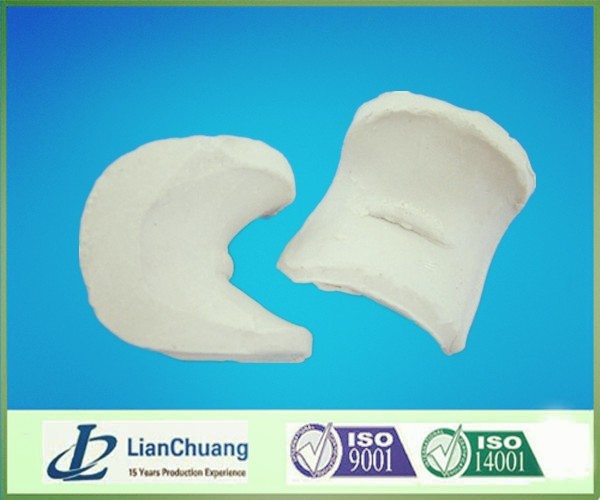

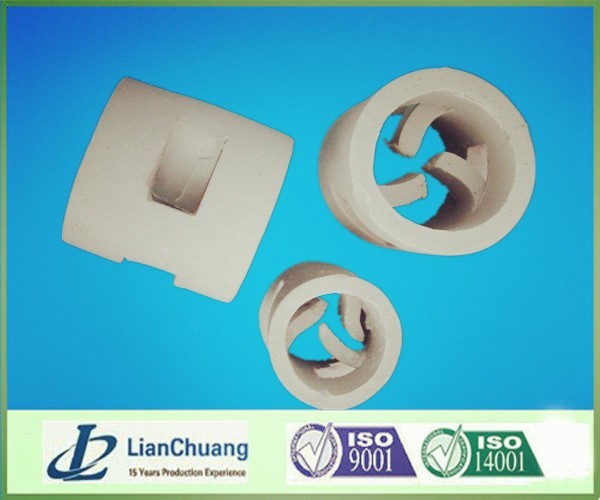

Product Description

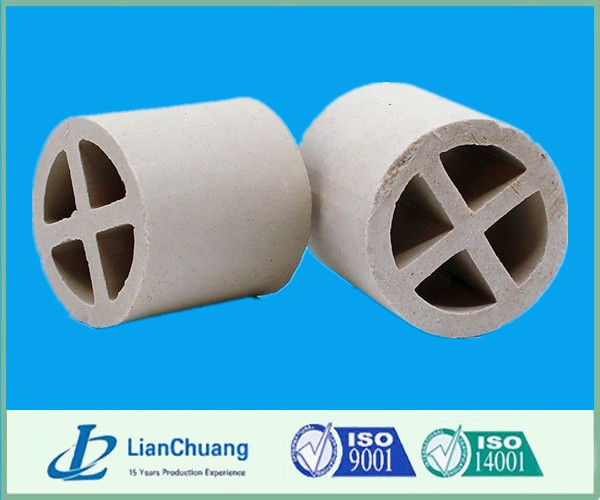

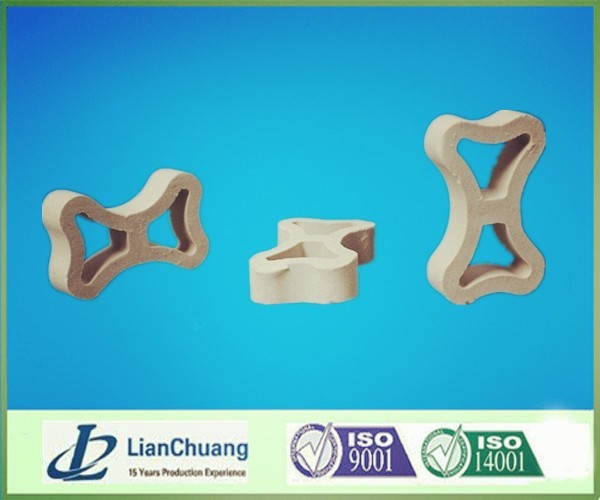

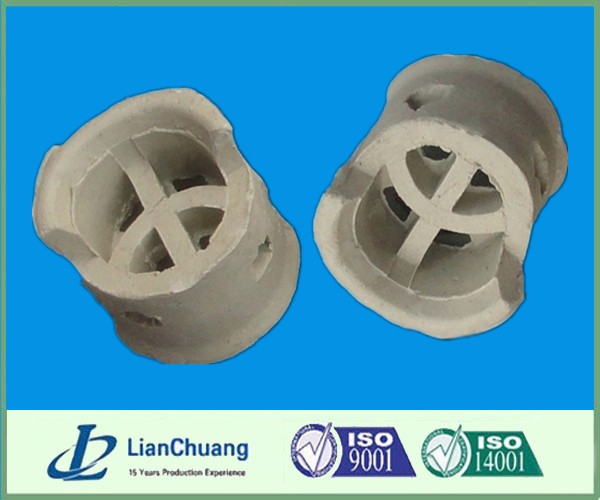

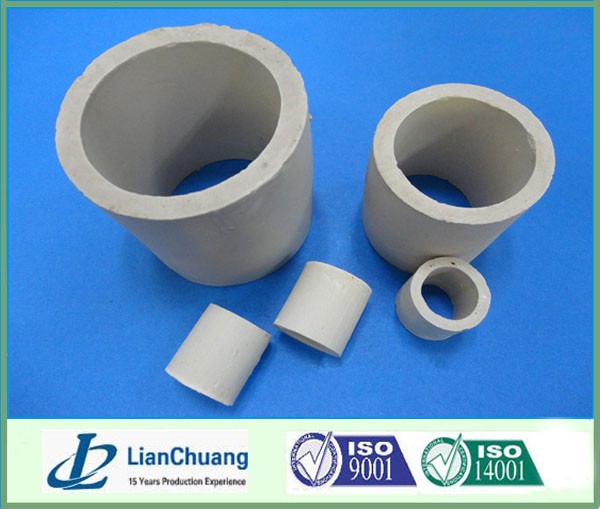

ceramic saddles is improved from berl saddles , cerami intalox saddles are between the ring shape and the shape of the saddle, and therefore maintain both their advantages. This design has two different radii of curvature that provide a greater degree of randomness in the packed bed.The availability of the mass transfer surface will be enhanced efficiently, and it has favorable liquid distributing capability.

ceramic saddles offer exceptional resistance to acids and heat, making them ideal for a diverse range of applications. They withstand corrosion from various inorganic and organic acids, as well as organic solvents, with the exception of hydrofluoric acid. Their versatility extends to both high and low-temperature conditions, allowing for widespread use. And ceramic intalox saddles ring’s ( ceramic saddle ) made from chemical porcelain, and it's fired at a very high temperature. So ceramic saddles have a high chemical resistance to acid, and its structure is conducive to the liquid gas distribution. Ceramic saddles'cost at a relatively low cost, because it’s continuous extrusion method production way.

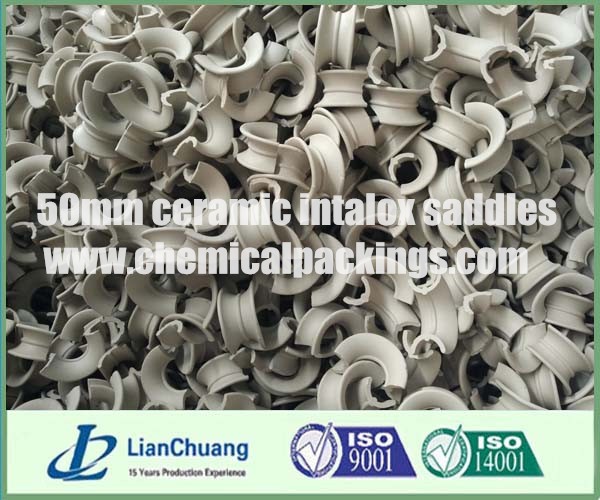

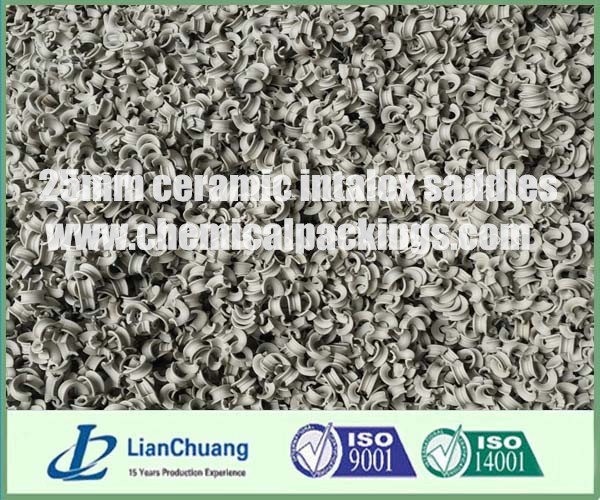

Available sizes for Ceramic saddles:

6mm,13mm,16mm,19mm,25mm,38mm,50mm,76mm,150mm

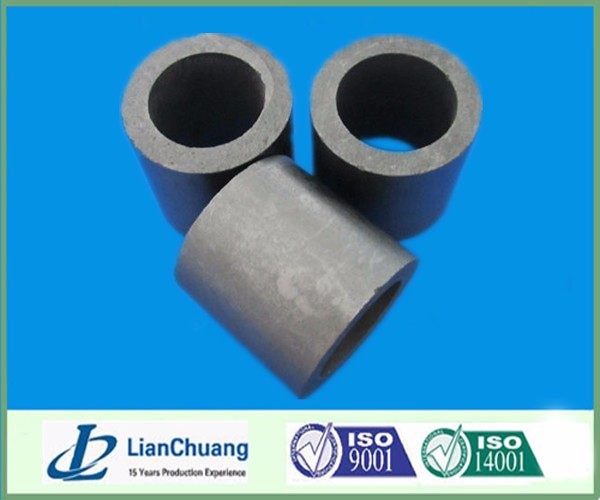

Application : Ceramic saddle rings are commonly used as heat transfer and corrosive acid applications, it can be applied in RTO ( regenerative thermal oxidizers ), dring tower , tail gas scrubbers, impasse towers, absorption tower, cooling tower, scrubber, regeneration tower etc.

Physical properties of Ceramic Saddles:

Nominal size | 1/2″ | 5/8″ | 3/4″ | 1″ | 1.5″ | 2″ | 3″ |

13mm | 16mm | 19mm | 25mm | 38mm | 50mm | 76mm | |

Number per m3 | 610,000 | 269,000 | 146,000 | 59,000 | 19,680 | 8,243 | 2,400 |

Package density (kg/m3) | 780 | 700 | 670 | 630 | 580 | 550 | 530 |

Free volume (%) | 68 | 71 | 75 | 77 | 80 | 79 | 75 |

Surface area (m2/m3) | 647 | 535 | 350 | 254 | 180 | 120 | 91 |

Specific gravity (g/cm3): | 2.3 | ||||||

Water absorption (%) | <0.3 | ||||||

Acid resistance (%) | >99.6 | ||||||

Max operating temp. | 1100℃ | ||||||

Porosity (%) | <1 | ||||||

Moh’s hardness (scale) | >6.5 | ||||||

Thermal conductivity (w/m.k): | 0.9-1.0 | ||||||

Specific heat(j/kg℃): | 850-900 | ||||||

Chemical Composition

SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O+Na2O | Other |

>73% | 17-23% | <1.0%< | <0.5% | <0.5% | 2-4% | <0.1% |

Package: Plastic bag, Jumbo bag, Carton box, Metal Drum etc.

Why Choose Us:

Cost Advantage: Operating within our factory premises provides us with a significant cost advantage, enabling us to offer competitive prices and providing you with more options for your procurement needs.

Excellent Quality: Our ceramic saddles are renowned for their superior quality, exhibiting outstanding resistance to acids, alkalis, and high temperatures, performing exceptionally well in various extreme environments.

Certified Manufacturer: We are a certified manufacturer, meeting industry-specific certification standards. This ensures that our products are reliable, compliant with standards, and instills the utmost confidence and support in your procurement decisions.

Timely Delivery: We prioritize customer experience, ensuring that each order is delivered accurately and on time. We understand that, for you, time is of the essence.

Contact Us:

E-mail:sales@chemicalpackings.com

WhatsApp:86-18079939336