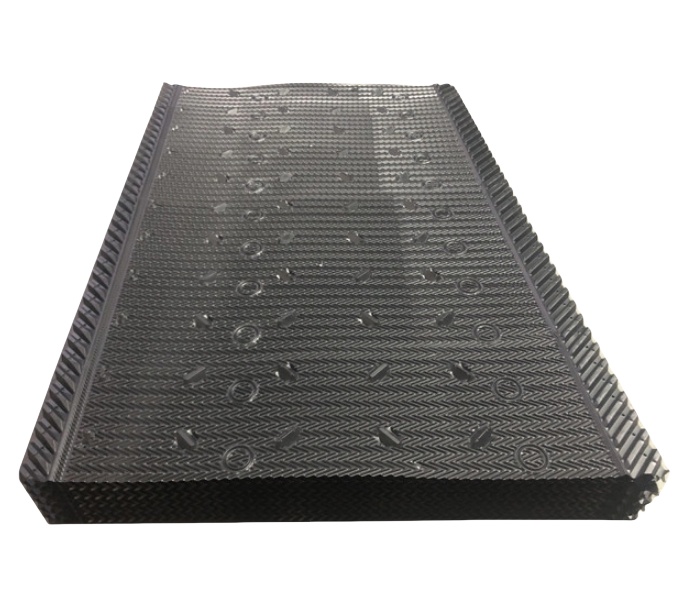

Cooling towers are vital in various industrial and HVAC applications, primarily for dissipating heat from water used in processes. Hanging pvc fill, which comprises lightweight vertical panels or sheets, allows water to spread over a larger surface area. This design enhances air exposure, promoting efficient heat exchange. Typically made from durable materials like PVC or polypropylene, hanging fills resist corrosion and biological growth.

| Material: | PVC PP |

| Dimension | Width usually be 1220,1500,915,813,length can be meet your demands |

| Thickness | usually be 0.25mm,0.38mm,also can be customized |

| Usage: | For cooling tower |

| color | clear black green blue |

| Shaping mode | Plastic extrusion mould |

| Minimum Order: | 1000 PCS |

| Packaging Details: | In bundle,wooden pallet or as your request |

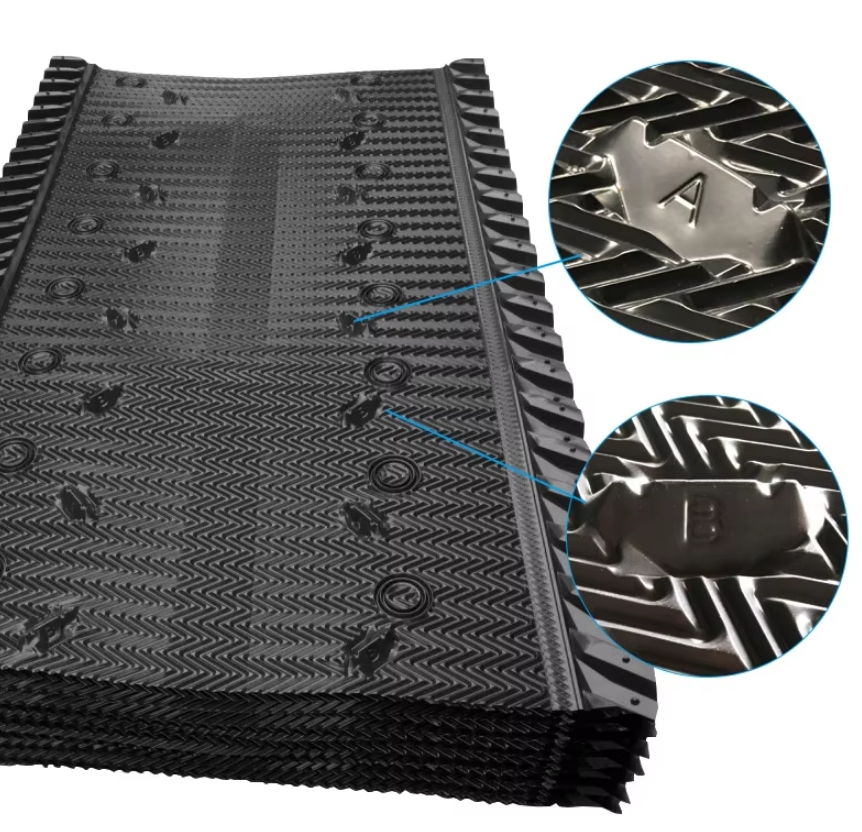

Types of Hanging cooling tower fill

BAC Cooling Tower Fill: This fill is crucial for gas-water exchange within the cooling tower, significantly enhancing efficiency while ensuring safe, economical operation. Advances in plastic manufacturing have led to the development of "S" shaped and oblique wave patterns in counter-current tower fills, which facilitate effective heat dissipation and low resistance to airflow, making them suitable for various cooling tower sizes.

Counterflow Hanging Marley Cooling Tower Fill: Known for its effectiveness in Marley cooling towers, the MC75 fill media is one of the most popular PVC options. Designed for counterflow systems, it features crossed corrugations that optimize heat transfer and maintain uniform spacing. Made from UV-resistant, chemically inert PVC, the MC75 fill also has a low flame spread rating and is self-extinguishing. Replacing traditional splash fills with MC75 can reduce fill height, leading to lower pumping energy and increased cooling capacity.

Constructed from 0.015-inch thick, UV-stabilized, chemically-resistant polyvinyl chloride (PVC), the MC75 fill features a flame spread rating below 25 according to ASTM E-84, classifying it as self-extinguishing. The material is extruded and manufactured to strict specifications prior to its thermoforming. Replacing traditional splash fills with MC75 in counterflow towers typically results in a lower fill height, which in turn reduces pumping head.

This upgrade increases the cooling capacity of the tower, allowing for enhanced performance with less fan energy consumption. The fill pack's depth can be adjusted to optimize air travel for effective heat transfer within a single layer. If additional air travel is needed, only one extra layer of fill is permitted to limit the number of interfaces, thereby minimizing potential clogging. The MC75 fill can be suspended from structural supports or bottom-supported in almost any counterflow cooling tower, regardless of its age or manufacturer.

Installation Considerations

Proper installation of hanging fill is critical and involves:

- Compatibility: The fill should match the cooling tower's dimensions to prevent water bypass and ensure even distribution.

- Ventilation: Sufficient airflow around the fill is necessary to maximize evaporation.

- Water Distribution: An efficient distribution system is essential for uniform water flow over the fill.

Maintenance Practices

Regular maintenance is key to the durability and effectiveness of hanging fill:

- Inspection: Conduct routine checks for damage, fouling, or scaling to catch problems early.

- Cleaning: Depending on water quality, cleaning may be needed to eliminate biofilm and debris.

- Replacement: Over time, hanging fill can wear out; regular evaluations will help determine when to replace it.

By concentrating on these factors, facilities can enhance the efficiency of hanging cooling tower fill, ensuring optimal heat transfer and extended operational life.

Specification Detail

Hanging Cooling Tower Film Fill Media Anti-UV PVC Material Cooling Tower Filler Weight:

| NOMINAL GAUGE | DRY WEIGHT | ||

| mils | mm | lbs/ft3 | kg/m3 |

| 10 | 0.25 | 1.8 | 28.8 |

| 15 | 0.38 | 2.6 | 41.6 |