Lamella Clarifier ( lamella separator ) is an advanced device designed for efficient water and wastewater treatment. It serves as a continuous sedimentation unit that effectively removes solid particles from liquids. Utilizing its distinctive lamella plate configuration, the Lamella Clarifier significantly improves sedimentation efficiency. This system is widely applied in industrial and municipal water treatment processes. Compared to conventional sedimentation tanks, the Lamella Clarifier offers several benefits, such as a smaller footprint, greater treatment capacity, and reduced energy requirements, making it a crucial component of contemporary water treatment technologies.

Principle of Lamella Clarifier Operation

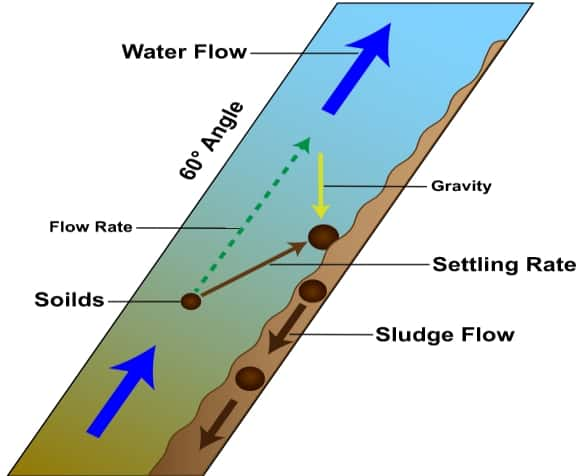

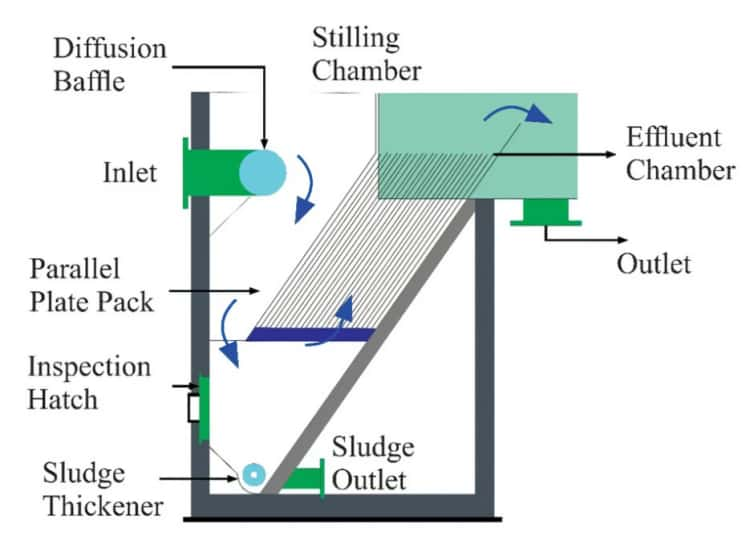

The Lamella Clarifier functions as an open, gravity-based system. It consists of a series of closely spaced, inclined plates. Pre-treated water containing suspended solids flows through the gaps between these plates and along their surfaces.

Variables such as path length, spacing, and plate angle are key design factors. As water flows through the inclined plates, solid particles, being denser than water, settle onto the plate surfaces. These particles then slide down the inclined surfaces, collecting in a sludge hopper at the bottom.

Primary and secondary treatment systems are typically used to remove up to 85%-95% of contaminants from wastewater before disinfection and discharge. However, stand-alone systems like Lamella Clarifiers are better suited for achieving higher efficiency in solids removal, maximizing recovery.

Wastewater treatment requires particles to settle to meet water quality standards. Denser particles naturally sink under gravity. The rate at which this occurs is referred to as settling velocity, which can be calculated using Stokes' Law:

Stokes' Law:

v = (2/9) * (d1 - d2) * g * r² / η

This formula explains why a Lamella Clarifier can process more water in a shorter time while requiring less space. In this system, water moves upward through inclined plates, enabling faster settling of particles as they travel a shorter distance. The Inclined Plate Lamella Settler Separator plates enhance settling surface area, and gravity facilitates particle deposition while the clarified water rises. This design accelerates the clarification process, particularly in space-constrained environments. The quicker particles reach the plates, the faster clarification occurs.

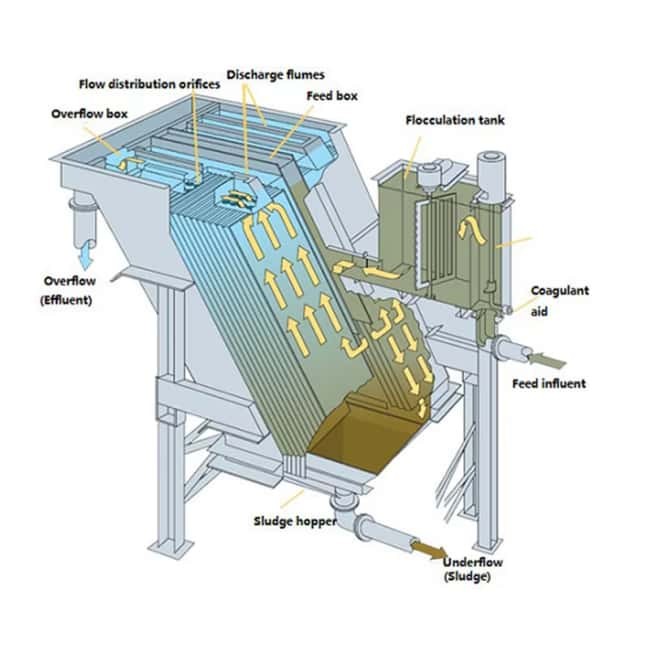

Key Components of Lamella Clarifier:

1. Tube Settlers (Lamella Plates):

tube settlers form the main element of the Lamella Clarifier. These inclined plates, typically set at a 45° angle, enable larger particles to settle via gravity as water passes through. Tube settler design significantly increases settling area, allowing efficient clarification in a compact space, improving throughput and performance.

2. Collection Tank:

Once the water has passed through the inclined plates, the clarified liquid flows into the collection tank. This tank gathers the treated water for further processing or discharge.

3. Influent Channel:

The influent channel directs raw water into the clarifier. Equipped with flow regulation mechanisms, it ensures even distribution across the plates for optimal sedimentation.

4. Sludge Removal System:

During operation, settled sludge accumulates beneath the inclined plates. A sludge removal system periodically clears this buildup to maintain operational efficiency. Common methods include automated or manual sludge troughs.

5. Effluent Outlet:

The treated water exits the Lamella Clarifier through the effluent outlet, ready for either subsequent treatment stages or direct discharge.

Purpose of a Lamella Clarifier

Inclined Plate Lamella Settler Clarifiers are designed to remove significant quantities of solids from wastewater. They rely on gravity to allow denser particles to settle on the inclined plates while clarified water flows freely. Coagulants and polyelectrolytes can enhance the process by forming larger flocs and neutralizing charges, enabling easier settling.

Occasionally, scum that doesn't settle on the plates may form. In such cases, scum removal systems are required. It's advisable to pre-treat wastewater to remove excessive oils or grease before using the clarifier, as only small amounts should enter the system. Skimmers can help capture residual oils.

Advantages of Lamella Clarifiers

Lamella Clarifiers offer distinct advantages over traditional sedimentation tanks:

1. Compact design: Inclined plates maximize effective settling area, reducing the tank's footprint. This feature is ideal for facilities with limited space, such as industrial plants.

2. Enhanced efficiency: Faster settling enabled by the plates ensures quicker and more effective separation of solids.

3. Lower maintenance: The self-cleaning design of the plates minimizes maintenance needs compared to conventional tanks.

4. Cost-effective: With a smaller initial investment and operating costs, Lamella Clarifiers are a budget-friendly choice.

5. Eco-friendly: Improved solids removal leads to cleaner effluent, reducing environmental impacts.

Benefits of Lamella Clarifier:

1. High space efficiency: Lamella Clarifiers can save over 85% of the space compared to traditional systems.

2. Simplified sludge handling: Compact design reduces manual interventions for sludge management.

3. Energy-efficient: Most models require minimal mechanical components, such as scrapers, lowering energy demands.

4. Durable and low-maintenance: Few moving parts ensure reliability and ease of maintenance.

How to Use a Lamella Clarifier

1. Account for flow rate: Design the system based on peak flow rates to ensure efficiency.

2. Select appropriate size: Match the clarifier's size to the anticipated flow rate and solids load for optimal performance.

3. Monitor sludge buildup: Regularly check sludge levels to prevent overflow and remove as necessary.

4. Maintain weirs: Periodic inspections ensure proper functionality and prevent solids carryover.

5. Clean screens: Regular cleaning of inlet screens prevents clogs and maintains flow.

6. Inspect plates: Ensure plates remain undamaged and unobstructed for consistent efficiency.

7. Control pH and temperature: Maintain appropriate levels to optimize settling and prevent inefficiency.

Applications of Lamella Clarifiers

These clarifiers are ideal for industries requiring efficient solids separation. Common applications include:

1. Sand and gravel processing

2. Recycling plants

3. Ceramics and glass industries

4. Chemical production

5. Energy sector (cooling water treatment)

6. Tunnel construction sites

7. Landfill management

8. Heavy metal treatment

9. Municipal wastewater management

10. Power plant scrubbers and lime treatment

11. Chemical and mining concentration processes

Conclusion

With stricter environmental regulations and rising water scarcity concerns, the Lamella Clarifier is indispensable in modern water treatment systems. Its efficiency, versatility, and compact design make it the preferred solution for engineers and designers. Continuous innovation ensures its pivotal role in future water treatment advancements.