Wastewater treatment is an essential process in maintaining public health and environmental sustainability. Innovations in this field have led to the development of advanced technologies that enhance the efficiency and effectiveness of treatment processes. One such innovation is the Mutag BioChip a high-performance biofilm carrier developed by the German company Multi Umwelttechnologie AG. This article provides an in-depth exploration of the Mutag BioChip, detailing its features, benefits, and real-world applications in wastewater treatment.

Key Features of Mutag BioChip™

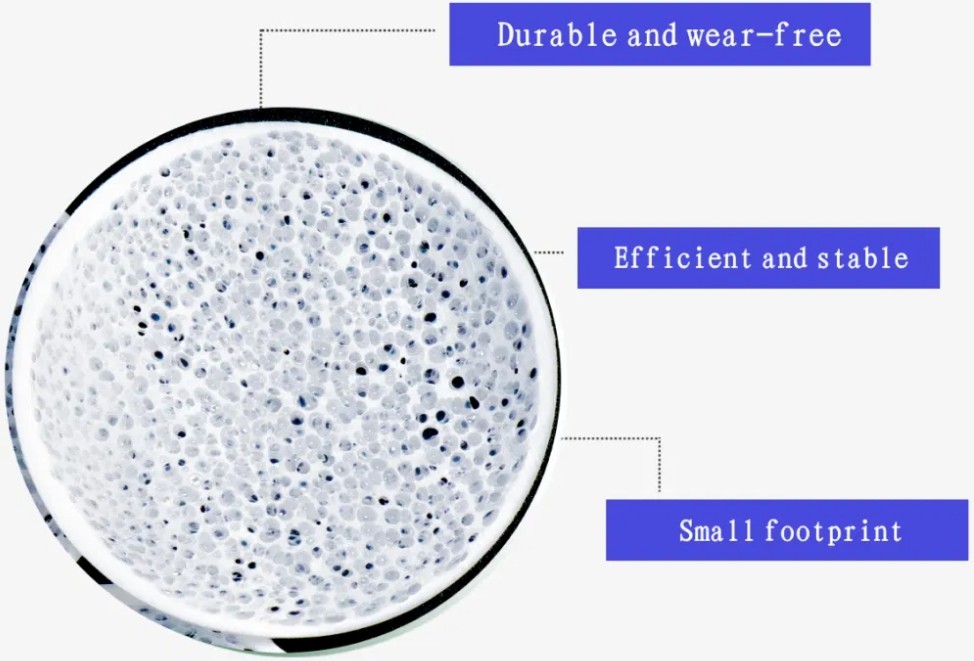

Innovative Design and Surface Area

The Mutag BioChip™ stands out due to its innovative design, which offers a remarkably high active surface area. The carrier provides more than 3,000 square meters per cubic meter (914 square feet per cubic foot) of active surface area, a figure that far surpasses most traditional biofilm carriers. This extensive surface area is achieved through a meticulously designed pore system, which supports the attachment and growth of microorganisms, particularly nitrifying bacteria. These bacteria are crucial for the nitrification process, a key step in the biological treatment of wastewater.

The Mutag BioChip™ is designed to protect these sensitive microorganisms from external mechanical forces. The carrier’s structure, approximately 1 mm thick, allows for optimal diffusion of substrates and oxygen from both sides, ensuring that the bacteria receive the necessary nutrients and oxygen to thrive. This design also promotes thin biofilm formation, which is essential for efficient biological processes.

High Nitrification Efficiency

Nitrification is a critical process in wastewater treatment, involving the conversion of ammonia into nitrites and then into nitrates by specific bacteria. The Mutag BioChip™ is particularly effective in enhancing nitrification efficiency. The chip’s design ensures that nitrifying bacteria are well-protected and provided with an ideal environment for growth and activity. The result is a significantly higher nitrification rate compared to conventional biofilm carriers, making the Mutag BioChip™ an ideal choice for wastewater treatment plants aiming to improve their biological treatment stages.

Clog-Free Operation

One of the most significant challenges in wastewater treatment is the potential for clogging within biofilm carriers. Clogging occurs when excessive biomass accumulates, blocking the flow of water and reducing the effectiveness of the treatment process. The Mutag BioChip™ addresses this issue with its fine and detailed pore system. The biofilms form within these pores, shielded from mechanical impacts and shear forces that could otherwise cause clogging.

The movement of the BioChip™ carriers within the wastewater generates shear forces on the carrier’s exterior. These forces continuously abrade any excess biomass that might protrude from the pores, ensuring that the biofilm remains thin and effective. This self-cleaning mechanism prevents clogging and maintains consistent performance over time, even in high-load conditions.

Energy Efficiency and Cost Savings

The Mutag BioChip™ is not only effective but also energy-efficient. Its specific shape and density allow it to be suspended in wastewater with minimal energy input. This reduces the amount of agitation energy required, typically supplied through process air, thereby lowering the operational costs of wastewater treatment plants.

In addition to energy savings, the Mutag BioChip™ also offers cost benefits in terms of transport and installation. Because of its high surface area, less carrier volume is required compared to traditional biofilm carriers, which reduces transportation costs. Moreover, the need for smaller tank volumes translates into savings in construction expenses, particularly in new plant installations or upgrades where space is limited.

Flexibility and Scalability

One of the unique advantages of the Mutag BioChip™ is its flexibility in adapting to various treatment capacities. Existing wastewater treatment plants can easily be upgraded by simply adding more BioChip™ carriers, increasing the treatment capacity without the need for extensive infrastructure changes. This scalability is particularly beneficial for plants that need to handle increased loads due to population growth or industrial expansion.

For instance, conventional biofilm carriers typically reach their maximum capacity at around 60% media filling. In contrast, the Mutag BioChip™ can be added to increase capacity well beyond this limit, without the need for additional reaction tanks. This capability not only enhances the plant’s performance but also saves significant costs and time associated with building new infrastructure.

Favorable Price-to-Surface Area Ratio

Another key advantage of the Mutag BioChip™ is its favorable price-to-surface area ratio. When evaluating the cost-effectiveness of biofilm carriers, it is essential to compare the price relative to the active surface area provided rather than just the volume of the carrier. The Mutag BioChip™ offers a much more competitive price per square meter of active surface area compared to many other carriers on the market. This efficiency means that not only does the BioChip™ perform better, but it also offers greater value, making it a cost-effective solution for wastewater treatment facilities looking to maximize their budget.

Abrasion and Wear Resistance

Durability is another area where the Mutag BioChip™ excels. The design of the BioChip™ ensures that each carrier element is lightweight relative to its size. This characteristic minimizes the impact forces when the carriers come into contact with each other, significantly reducing wear and tear. Unlike some heavier, tubular carriers that may break or degrade over time, the Mutag BioChip™ maintains its structural integrity even after prolonged use. This resistance to abrasion and wear ensures that the carriers have a long operational life, reducing the need for frequent replacements and contributing to lower long-term operational costs.

Real-World Applications of Mutag BioChip™

Case Study: Oberes Surbtal Sewage Treatment Plant, Switzerland

The practical benefits of the Mutag BioChip™ can be clearly seen in its application at the Oberes Surbtal sewage treatment plant in Switzerland. Before its upgrade, the plant operated using the traditional activated sludge process and was designed to treat sewage equivalent to 16,000 population equivalents (PE). However, as the demand increased, it became necessary to enhance the plant’s capacity and efficiency.

Between 2012 and 2013, the plant underwent a significant upgrade, during which the Mutag BioChip™ carriers were introduced into the nitrification zones. This upgrade was conducted by Techfina SA, a Swiss company, in close collaboration with Multi Umwelttechnologie AG. The redesign involved converting the plant into a hybrid system, combining the activated sludge process with the Moving Bed Biofilm Reactor (MBBR) technology, which incorporated the Mutag BioChip Media.

Post-upgrade, the plant’s capacity increased to treat 20,750 PE, a significant improvement from its original design. The hybrid process now efficiently handles the biological treatment stages, with the Mutag BioChip™ playing a crucial role in the enhanced nitrification process. The plant also saw improvements in oxygen supply, necessitated by the increased load, through the installation of more powerful blowers and high-performance plate-type membrane diffusers.

This case study not only demonstrates the effectiveness of the Mutag BioChip™ in improving plant performance but also highlights the ease with which existing facilities can be upgraded using this technology.

Other Global Installations

The success of the Mutag BioChip™ is not limited to Switzerland. The carrier has been deployed in several municipal sewage treatment plants worldwide. For instance, the city of Erkelenz in Germany has used Mutag BioChip™ since 2010 for clear water nitrification. Additionally, the technology has been successfully implemented in five municipal sewage treatment plants across Vietnam and Bangladesh since 2012.

In 2014, a sewage treatment plant near Leipzig, Germany, serving a capacity of 900 PE, was equipped with Mutag BioChip™ carriers. These installations have consistently demonstrated the BioChip’s ability to enhance wastewater treatment processes, regardless of the location or specific environmental conditions.

Containerized Wastewater Treatment Plants

The flexibility and efficiency of the Mutag BioChip™ also extend to containerized wastewater treatment plants. These are compact, fully self-contained units designed for rapid deployment and easy operation. By incorporating Mutag BioChip™ carriers, these plants can achieve significantly higher treatment efficiency, making them ideal for remote locations, emergency response scenarios, or temporary installations.

One notable example is a containerized wastewater treatment plant installed in Iraq in 2014. This plant utilizes Mutag BioChip™ technology to provide reliable and efficient wastewater treatment in a challenging environment, further underscoring the carrier’s versatility and effectiveness.

Application:

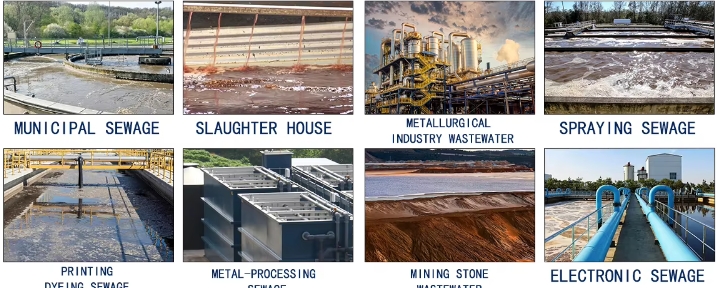

The Mutag BioChip mbbr media is highly adaptable and can be applied in various wastewater treatment scenarios, including:

Municipal Wastewater Treatment: Ideal for processing sewage in urban environments, this media ensures compliance with environmental standards by efficiently removing organic pollutants (BOD, COD) and nitrogen compounds.

Industrial Wastewater Treatment: Well-suited for handling wastewater from diverse industries such as metallurgy, food and beverage production, and electronics manufacturing, where it effectively removes high organic loads and specific contaminants.

Recirculating Aquaculture Systems (RAS): Excellent for lowering nitrogen levels to safe concentrations, this media maintains optimal water quality in fish farming operations, ensuring the health and safety of aquatic life.

Conclusion

The Mutag BioChip™ represents a significant advancement in wastewater treatment technology. Its innovative design, combined with its proven ability to enhance nitrification efficiency, prevent clogging, and reduce operational costs, makes it a valuable asset for both new and existing treatment plants. The BioChip™ also offers a favorable price-to-surface area ratio and is highly resistant to abrasion and wear, ensuring long-term durability and cost savings.

The success of the BioChip in real-world applications, from municipal sewage treatment plants in Europe and Asia to containerized units in remote locations, demonstrates its versatility and effectiveness. As wastewater treatment plants continue to face increasing demands due to population growth and industrial expansion, technologies like Mutag BioChip™ will become increasingly important. By offering a scalable, cost-effective solution that enhances treatment efficiency, the Mutag BioChip™ is well-positioned to become a standard in the industry, driving improvements in wastewater treatment processes worldwide.