Product Description

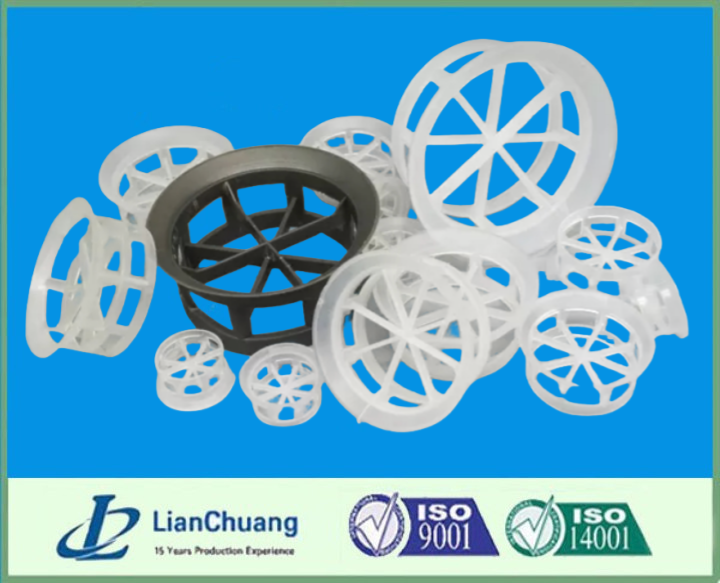

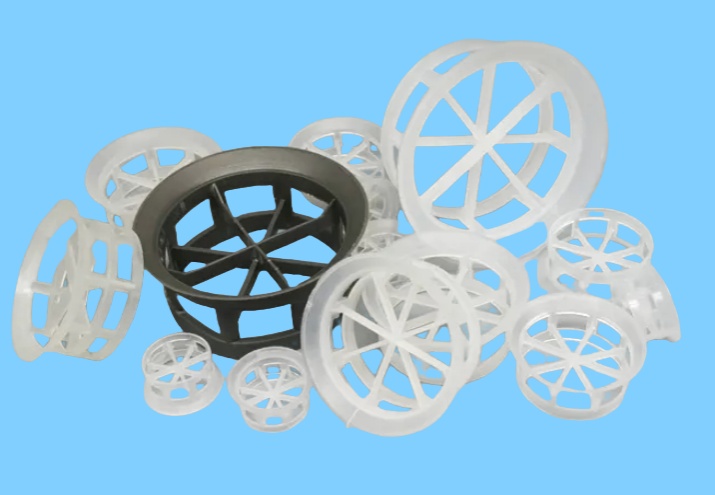

CMR packing also called cascade mini ring random packing, it's the first commercially successful third-generation random packing replacing the widely used P'all Ring . CMR packings' height is 1/2 or 1/3 ratio of the cascade ring’s diameter. Cascade mini ring added cone-shaped flanging at one edge. Cascade mini ring can be installed in a tower that tends to orient in a more structured way such that its inner surface could be more efficient.plastic cascade rings packing has features such as high free volume, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high mass transfer efficiency and so on. Cascade mini ring packing has material of plastic metal, ceramic material for different application.

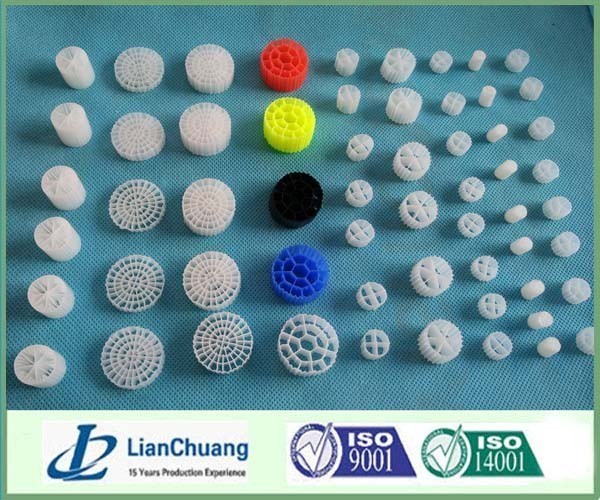

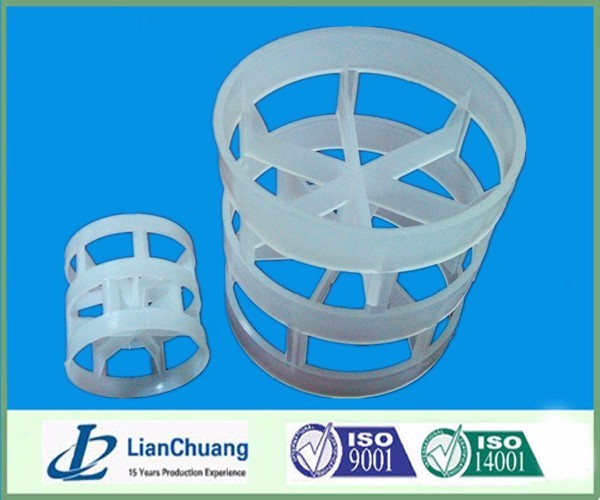

Plastic Cascade Mini Ring

Plastic Cascade Ring can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) and polyvinyiidene fluoride (PVDF). Plastic cascade mini ring chan used in media ranges from 60 to 150.Plastic cascade rings widely used in the packing towers in various separation, absorption, deabsorption equipment, normal pressure drop equipment, decarbonization of synthetic ammonia, desulphurization, separation of ethylbenzene,etc.

Specification of plastic cascade mini ring:

Spec. | D*H*T (mm) | Number per/m3 | Bulk density (kg/m3) | Surface area (m2/m3) | Free volume (%) | F Factor m-1) |

Dg16 | 16*8.9*1.1 | 299136 | 135.6 | 370 | 85 | 602.6 |

Dg25 | 25*12.5*1.4 | 81500 | 97.8 | 228 | 90 | 312.8 |

Dg38 | 38*19*1 | 27200 | 57.5 | 132.5 | 91 | 175.8 |

Dg50 | 50*25*1.5 | 10740 | 54.8 | 114.2 | 92.7 | 143.1 |

Dg76 | 76*37*3 | 3420 | 68.4 | 90 | 92.9 | 112.3 |

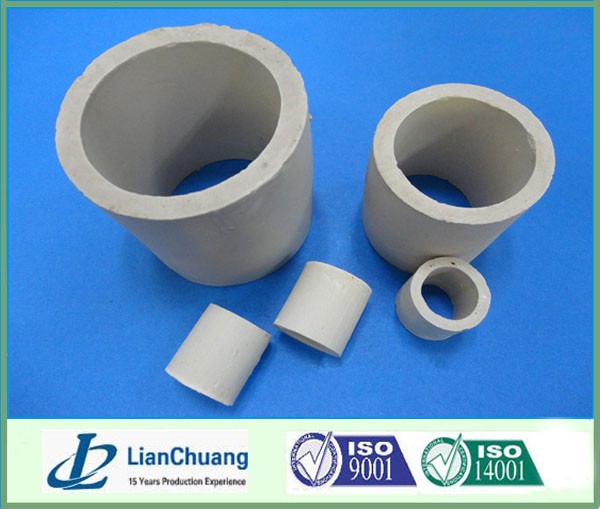

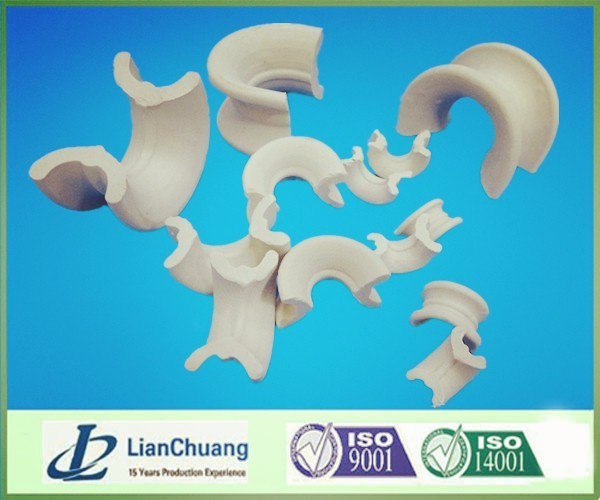

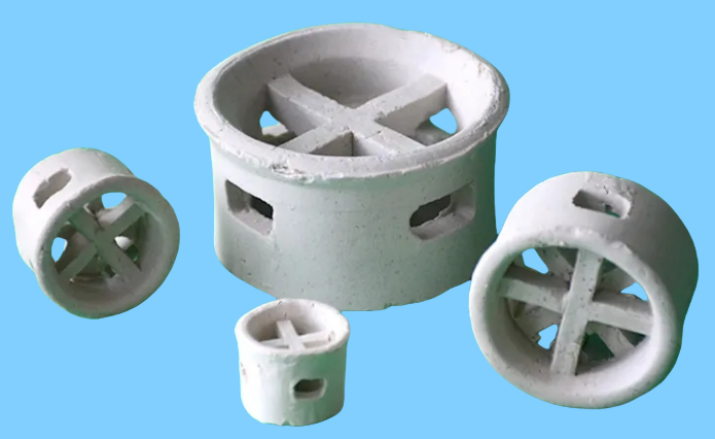

Ceramic Cascade Mini Ring Packing

ceramic cascade mini ring packing has excellent acid resistance and heat resistance. It can resist to corrosion of various inorganic acids, organic acids and organic solvents except hydrofluoric acid, and can be used in high or low temperature conditions. The packing can be used in the drying columns, absorbing columns, cooling towers, scrubbing towers and actifier columns in chemical industry, metallurgy industry, coal gas industry, oxygen producing industry, etc.

Specifiaction:

Normal | Diameter×Height×Thickness | Surface area | Void space | Bulk density | No.elements | Packing factor |

mm | mm | m2/m3 | % | kg/m3 | per/m3 | m-1 |

Φ25 | 25×15×3 | 210 | 73 | 650 | 72000 | 540 |

Φ38 | 38×23×4 | 153 | 74 | 630 | 21600 | 378 |

Φ50 | 50×30×5 | 102 | 76 | 580 | 9100 | 232 |

Φ76 | 76×46×9 | 75 | 78 | 530 | 2500 | 158 |

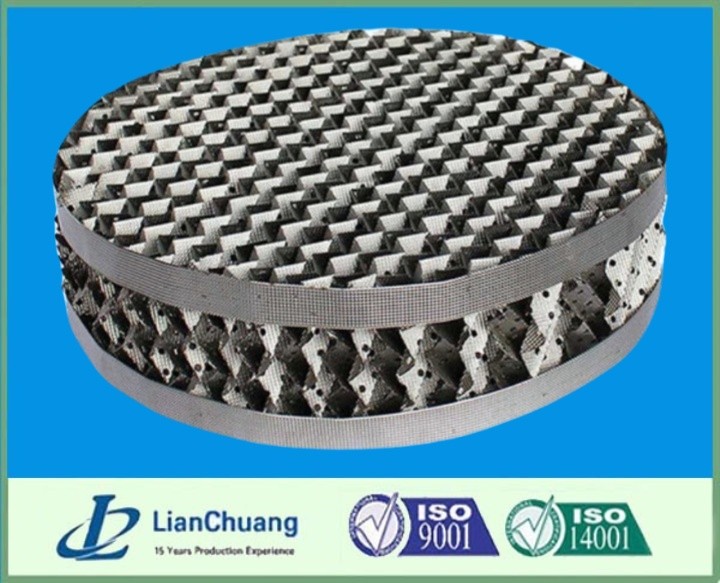

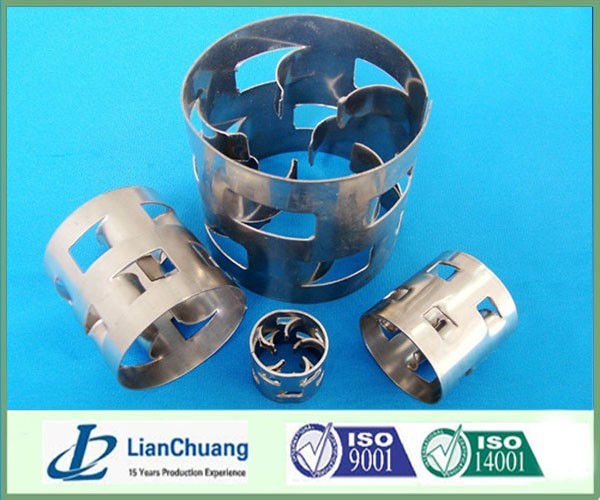

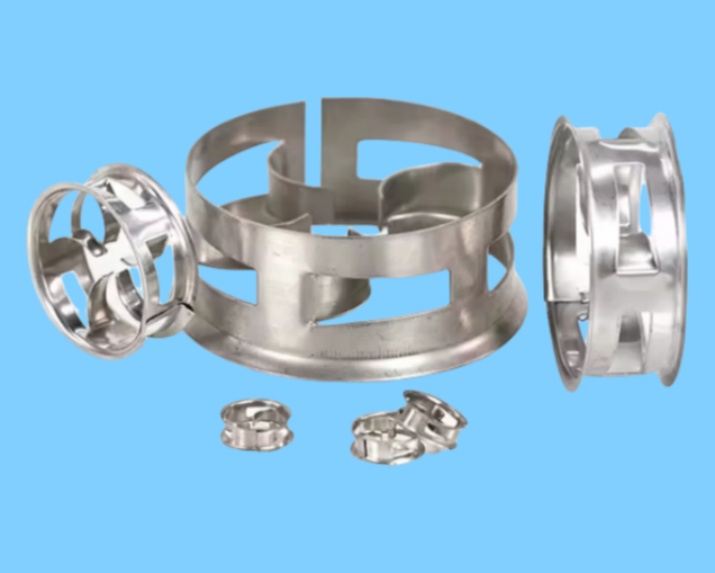

Metal Cascade Mini Ring Packing

metal cascade mini ring is made of materials like carbon steel, stainless steel or aluminum alloy, etc.It has features such as thin wall,heat resistant, high free volume, high capacity, low resistance, high separation efficiency and so on. It is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.Higher operational efficiency occurs because of the preferential orientation which ensures that in most of the rings surface are positioned vertically rather than horizontally, this is also an advantage for mass transfer.

Specification:

Specification | Surface | Free Vol. | Number | Weight | Packing-Factor |

mm | M2/m3 | % | Pc./m3 | Kg/m3 | m-1 |

25*12.5*0.5 | 220 | 93 | 97160 | 383.5 | 273.5 |

38*19*0.8 | 154.3 | 94 | 31890 | 465.6 | 185.8 |

50*25*0.8 | 109.2 | 95 | 11600 | 323.9 | 127.4 |

76*38*1 | 73.5 | 97 | 3760 | 214.5 | 81 |