Product Description

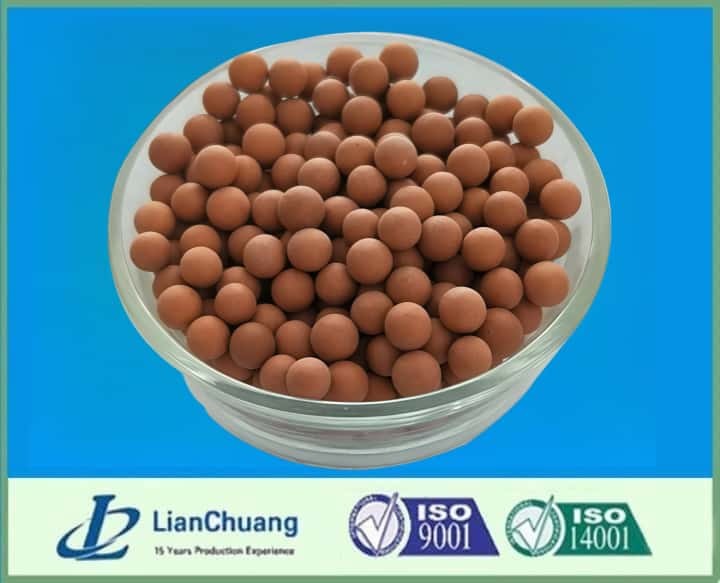

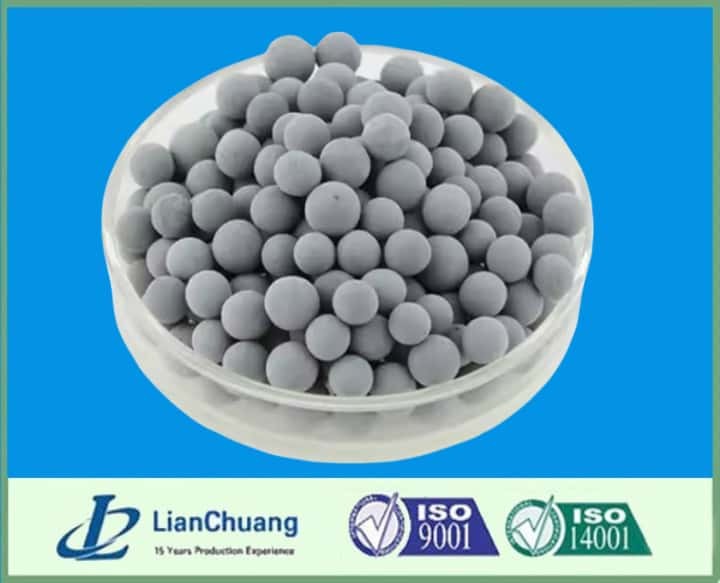

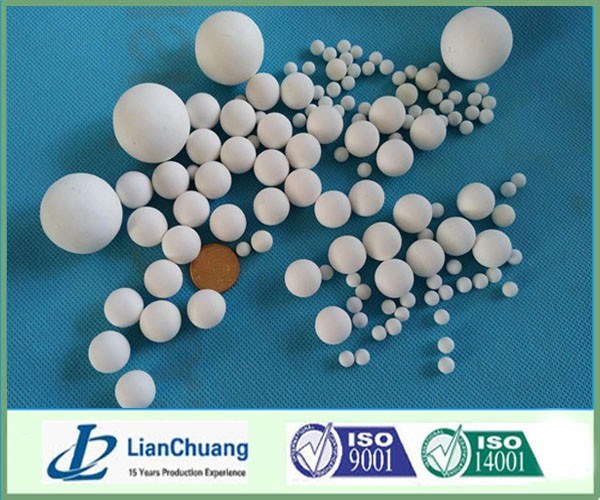

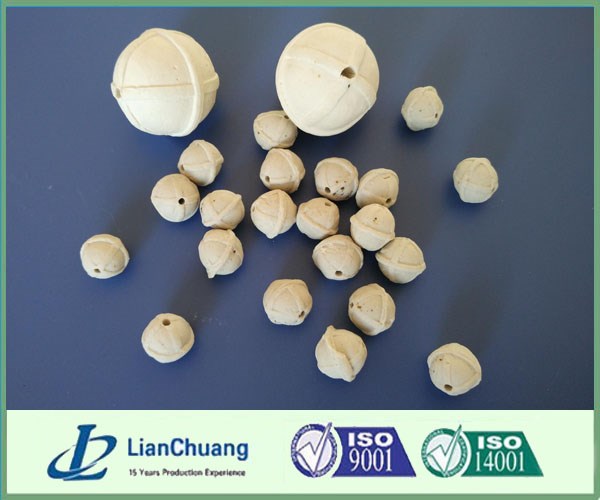

Alumina ceramic grinding media balls, 70% 92% 95% alumina grinding ball is one ideal ball mill grinding media that can improve grinding efficiency and keep no contamination. alumina grinding ball are made of pure Alumina, with the characters of high density and hardness, low abrasion and water absorption, thence our product of grinding ball has long service life, the quality of our product is very excellent.it is widely used in ceramics, cement, glass, enamel, paint, oil paint, refractory materials, chemical and other industries.

These balls are widely utilized in ball mills as abrasive media across industries such as ceramics, cement, enamel, and glass production. Their standout characteristics include exceptional density, hardness, strength, wear resistance, thermal stability, corrosion resistance, and non-contaminating properties. During the grinding or polishing process, ceramic balls remain intact and do not contaminate the materials being processed. They are categorized by alumina content, typically ranging from 60–70%, 65–75%, 95%, to 99%.

Key Features

- High density for excellent grinding efficiency

- Very low wear and reduced material loss

- Outstanding resistance to corrosion and chemicals

- Excellent cost-to-performance ratio

- Contamination-free milling for pure results

- Extended service life compared to traditional media

- Consistent size and shape for stable performance

Benefits

- Superior Wear Resistance: Alumina grinding balls last longer than standard media and keep materials pure, particularly valuable in ceramic glaze processing.

- High Density and Hardness: Reduce grinding time, expand effective milling capacity, and significantly improve efficiency.

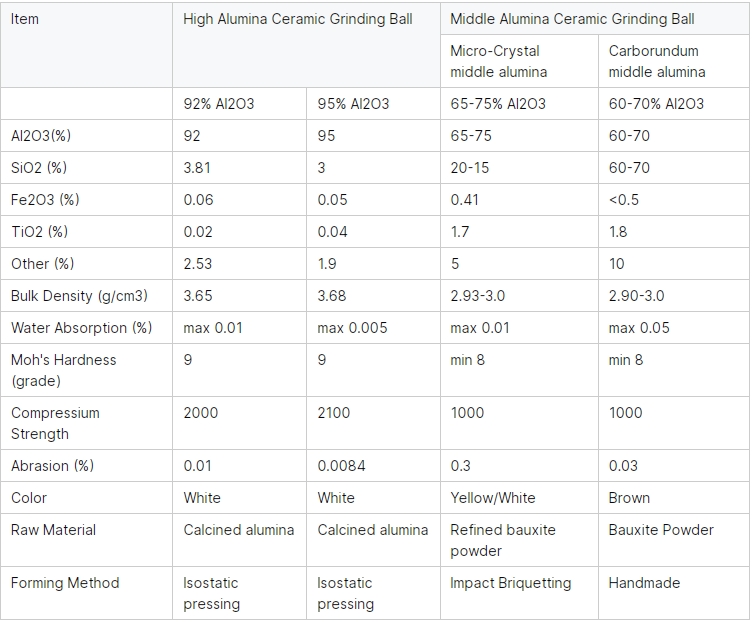

Technical Specifications

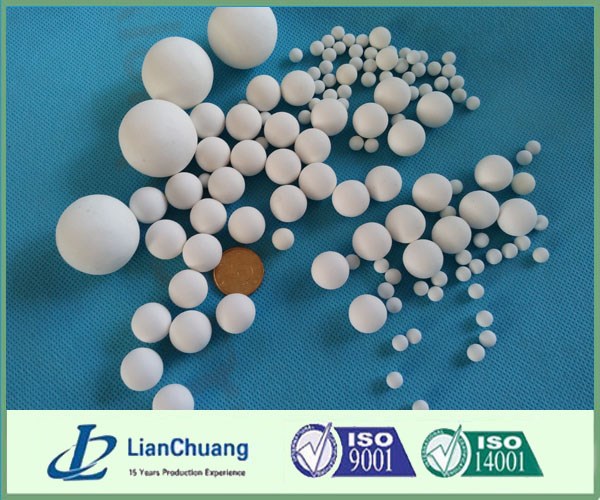

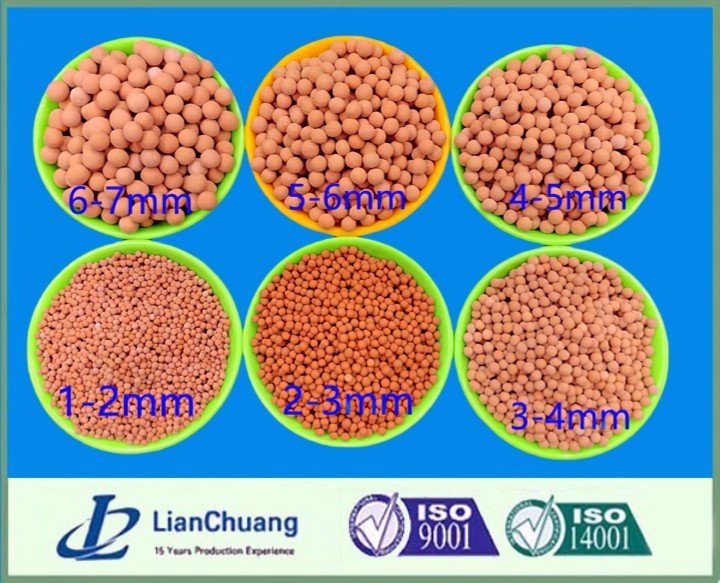

Available Sizes

Moulding Rolling Sizes: Ø0.5mm, Ø1mm, Ø2mm, Ø3mm, Ø4mm, Ø5mm, Ø6mm, Ø8mm, Ø10mm, Ø13mm, Ø15mm, Ø20mm, Ø25mm, Ø30mm

Isostatic Pressing Sizes: Ø25mm, Ø30mm, Ø35mm, Ø40mm, Ø45mm, Ø50mm, Ø60mm, Ø70mm, Ø80mm, Ø90mm

Applications

- High-speed stirred grinding mills

- Ball mills as abrasive media for ceramic raw materials

- Glaze material processing in ceramic, cement, and enamel factories

- Glass industry applications requiring high density and wear resistance

- Mixing and crushing in ceramics, glass, frits, chemical, and plastics industries