Product Description

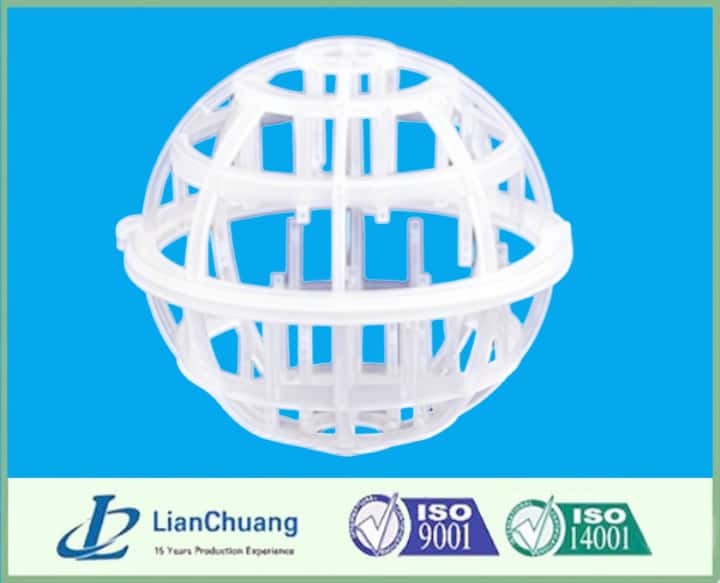

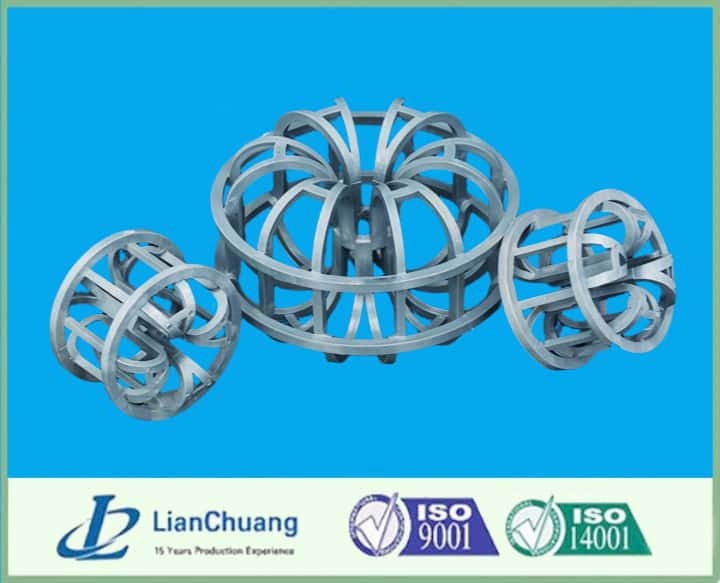

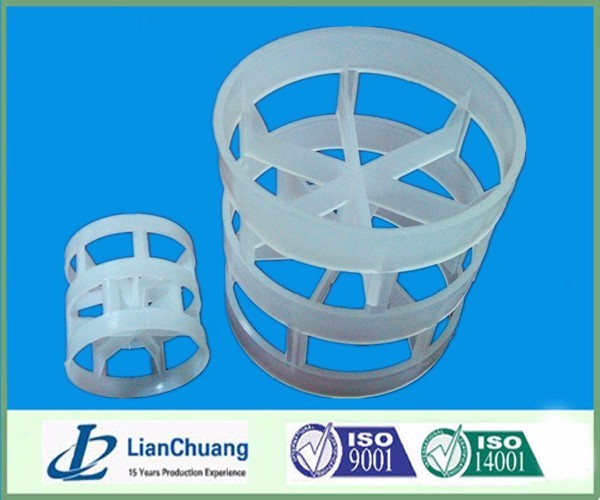

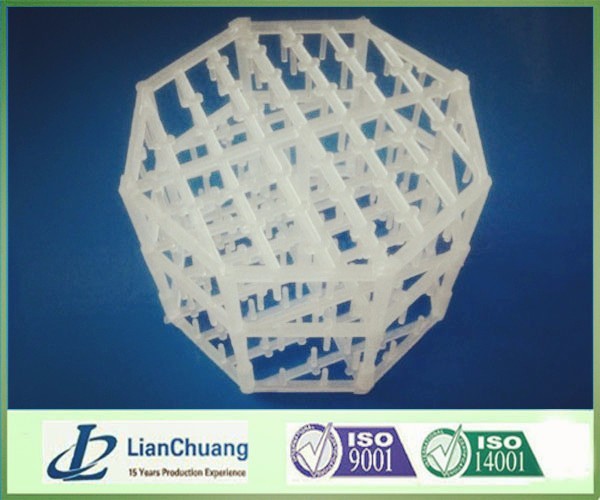

ENVIPAC tower packing is a spherical lattice-type random packing designed specifically for gas treatment applications. It is particularly suitable for processes with very low liquid loads, delivering improved performance in various industries, including chemical, petroleum, and environmental sectors. Thanks to its innovative design, ENVIPAC offers reduced pressure drop, enhanced load capacity, and superior separation efficiency.

Key Features:

1. Lower Pressure Drop:

The spherical lattice structure of ENVIPAC minimizes resistance to gas flow, resulting in reduced pressure drop during operation. This improves gas-liquid contact efficiency and lowers energy consumption in the tower.

2. Higher Load Capacity:

ENVIPAC offers a significantly higher load capacity compared to conventional high-performance packings. It is capable of handling higher gas and liquid flow rates, making it ideal for high-throughput processes and reducing the frequency of packing replacement and maintenance.

3. Superior Separation Efficiency:

With its optimized geometry and surface characteristics, ENVIPAC ensures effective separation of impurities during gas-liquid contact. This provides equal or better separation efficiency, leading to improved process performance.

4. Lower Specific Pressure Drop:

The unique design of ENVIPAC results in a significantly lower specific pressure drop, maintaining stable operation by better controlling the flow of gas and liquid within the tower.

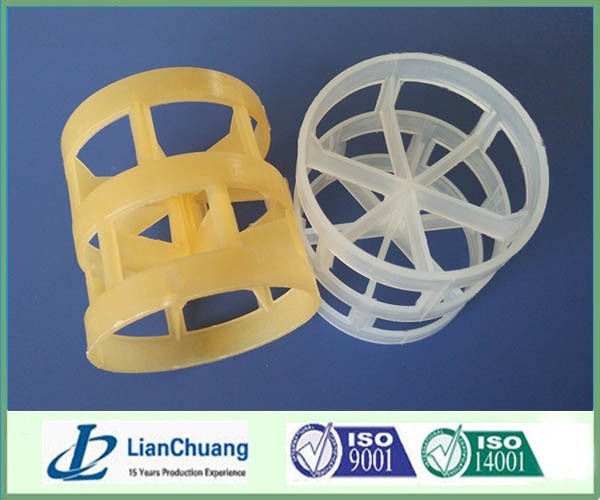

5. Durability and Material Selection:

ENVIPAC is constructed using high-quality engineering plastics such as polypropylene (PP), high-temperature polypropylene (PP-HT), polyethylene (PE), and polyvinylidene fluoride (PVDF). These materials offer excellent resistance to corrosion, high temperatures, and aging, ensuring consistent performance even in demanding conditions.

6. Ideal for Low Liquid Load Processes:

ENVIPAC is especially suited for gas treatment processes with low liquid loads, including gas absorption, desulfurization, and nitrogen removal. It provides better performance while simultaneously reducing operating costs.

Applications:

1. Chemical Industry: Gas absorption, gas purification, acid gas removal, volatile organic compound treatment.

2. Oil and Gas Industry: Gas desulfurization, denitrification, and refining process gas treatment.

3. Environmental Protection: Waste gas treatment and air pollutant removal.

4. Energy Industry: Natural gas and coal gas purification.

5. Food and Beverage Industry: Alcohol nitrogen removal, gas adsorption, and more.

Materials:

Polypropylene (PP), High-temperature Polypropylene (PP-HT), Polyethylene (PE), Polyvinylidene Fluoride (PVDF).

All materials are sourced from Germany, ensuring high quality and reliability.