Product Description

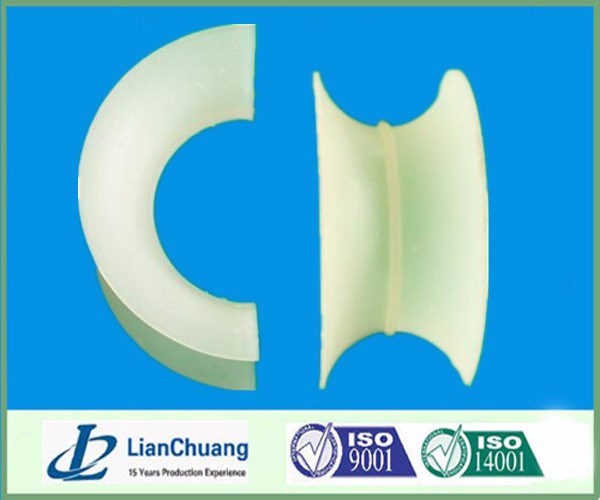

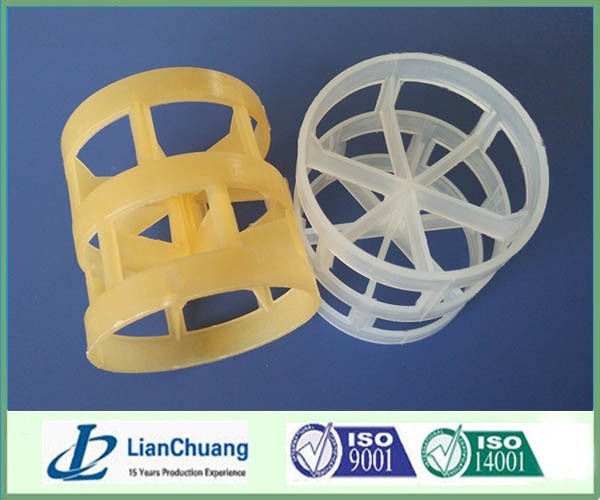

The plastic intalox saddles ring (plastic saddles) is the arc liquid channer so as to the flow air along with arc liquid channel. plastic intalox saddles ring has the characteristic of low pressure drop, large void space, large flux, high efficiency with low energy consumption etc. Furthermore plastic saddles have excellent distribution in tower packing, plastic saddles packing ring could be widely apply in the separation and absorption process ,device of reducing pressure.

Plastic intalox saddles ring (plastic saddles) is made of standing up to chemical corrosion materials, such as polyethylene(PE), polypropylene (PP) ,reinforced polypropyleneRPP,polyvinyl chloride(PVC), chlorides polyvinyl chloride(CPVC) and polyvinylidene fluoride(PVDF). It has feature such as high void ratio, low pressure drop, sufficient gas liquid contact, small specific weight, high mass transferring efficiency and so on. The operation temperature is 60-150. It is widely used in petroleum, chemical, alkali-chloride, coal gas and environment protection, etc.

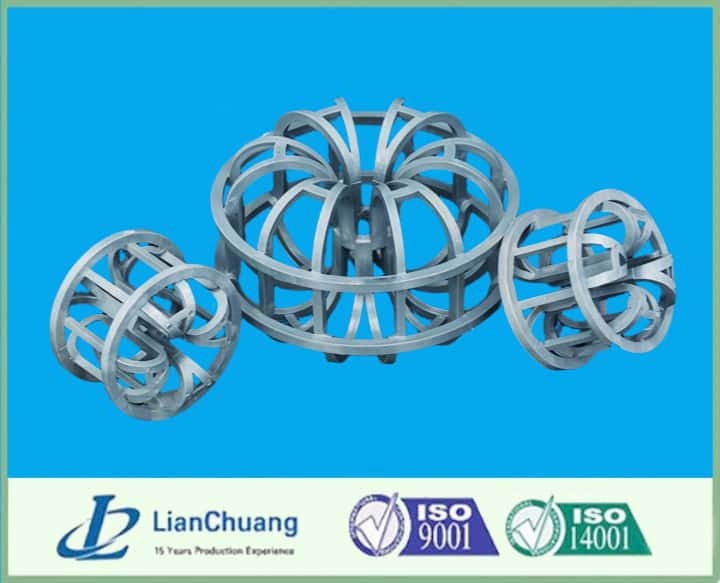

Features:

High void ratio, low pressure drop, reduced mass-transfer unit height, high flooding capacity, uniform gas-liquid distribution, low specific gravity, and enhanced mass transfer efficiency.

Advantages:

1.The unique structure allows for high throughput, minimal pressure loss, and excellent impact resistance.

2.It offers strong chemical corrosion resistance, large void space, energy efficiency, reduced operational costs, and ease of installation and removal.

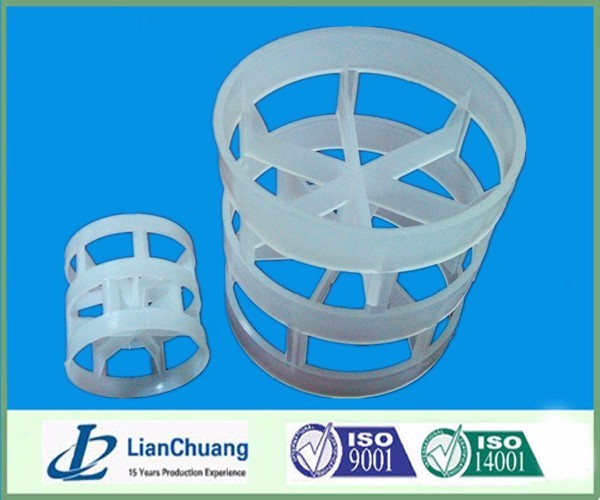

Plastic intalox saddle product model:

16mm, 25mm, 38mm, 50mm, 76mm

Specification of Plastic Saddles Advantages Features :

D*H*T | Number per m? | Bulk density | Surface area | Free volume | F factor |

(mm) | PCS | (kg/m?) | (m?/m?) | (%) | (m-1) |

25*12.5*1.2 | 97680 | 102 | 288 | 84.7 | 473 |

38*19*1.2 | 25200 | 63 | 265 | 95 | 405 |

50*25*1.5 | 9400 | 75.2 | 250 | 96 | 332 |

76*38*2.6 | 3700 | 59.2 | 200 | 97 | 289 |

Note:

Materl as PE, PP, PVC, CPVC, and PVDF per your needs.