Product Description

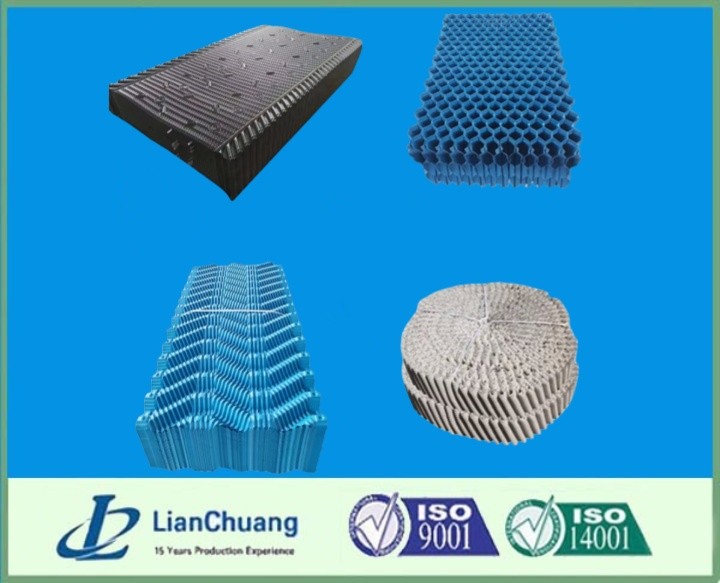

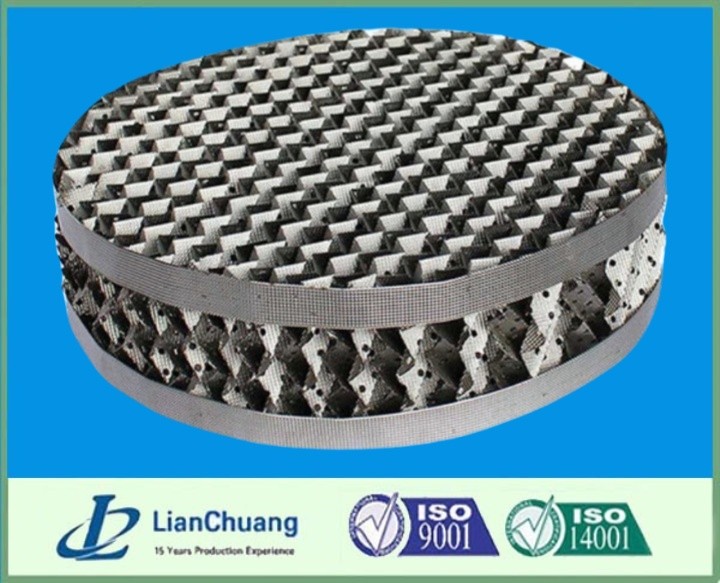

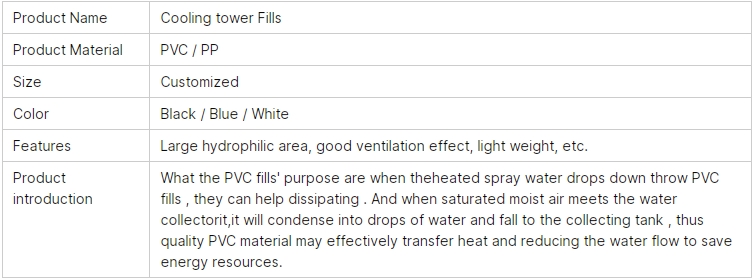

Filler Cooling Tower Packing, PVC Honeycomb Fill Pack in Cooling Tower commonly referred to as "fill," is essential for maximizing the contact area between water and air. This interaction is critical for effective heat transfer and evaporation, allowing water to cool efficiently as it descends through the tower. The choice of filler material can significantly influence a cooling tower's overall performance, making the selection of the right type crucial.

The Importance of Filler Cooling Towers Packing

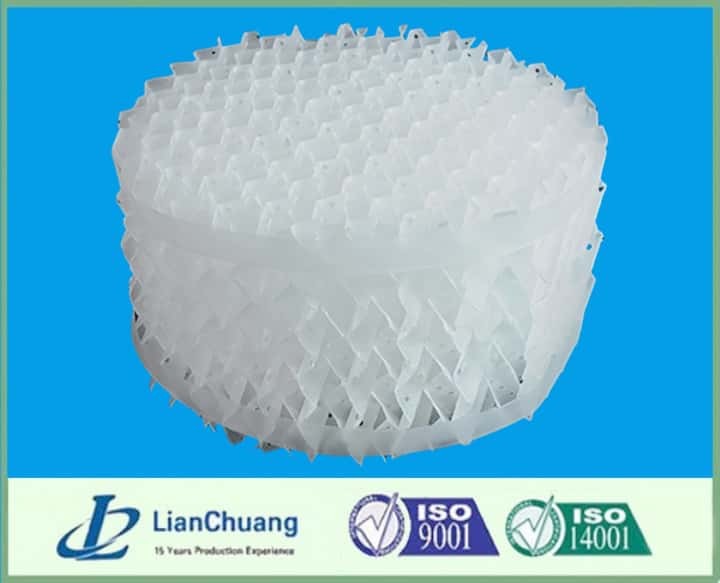

At the core of a cooling tower is its fill. Often described as a wet deck, filler cooling tower packing medium is vital for increasing the tower's surface area. A larger surface area allows for optimal contact between air and water, thereby enhancing evaporation rates. As water trickles through the fill due to gravity, PVC honeycomb fill Pack cools through direct interaction with the air flowing over it. The cooled water is then collected in a basin beneath the fill and pumped back into the system to absorb more heat. Meanwhile, the warm, moist air that exits the fill is released into the atmosphere at a safe distance to prevent interference with the tower's air inlets.

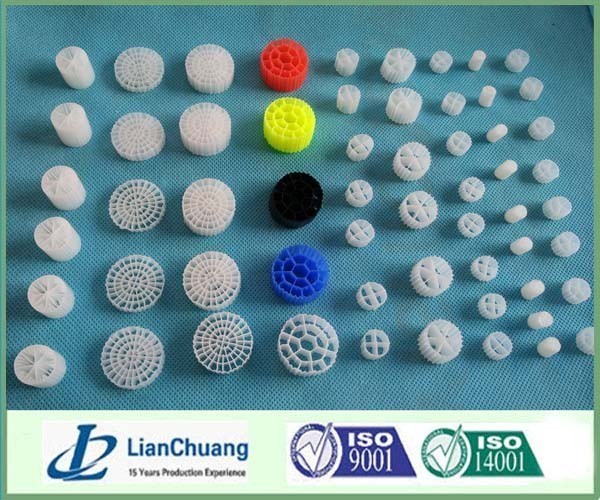

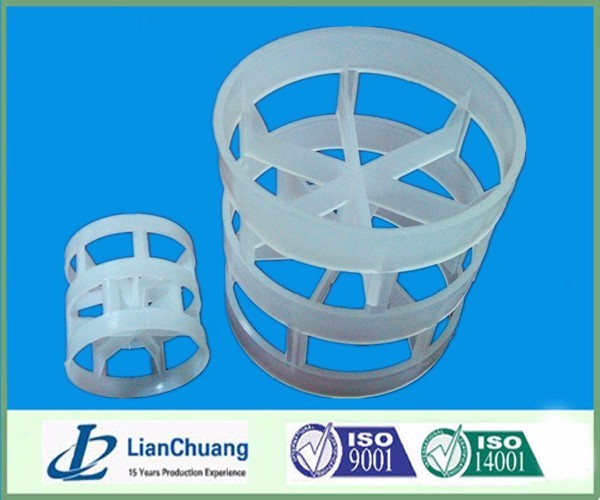

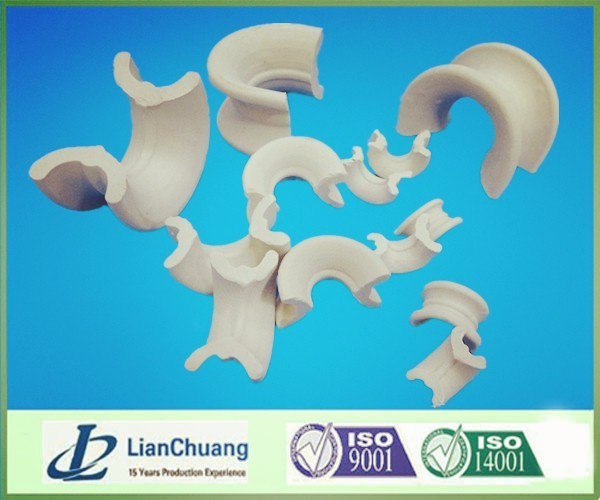

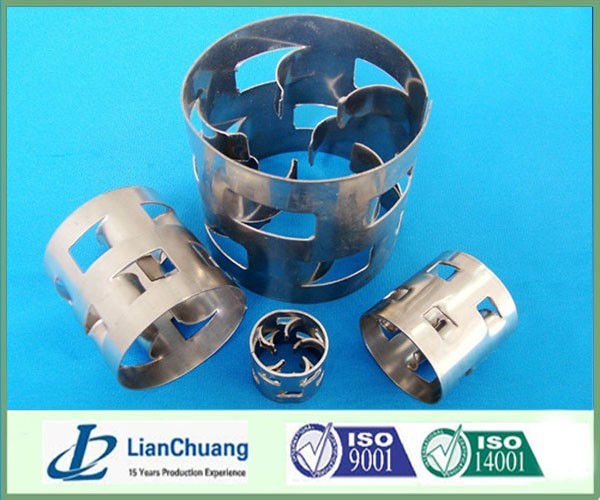

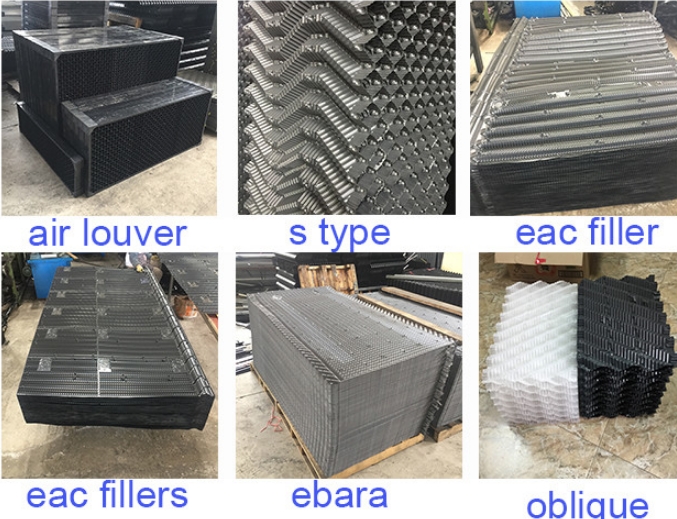

The fundamental principle behind cooling tower fill is to maximize the exposure time of water surface area to air. Film fills allow water to form thin sheets, which maximizes the surface area for interaction with airflow. These cooling tower film filler packing come in various shapes and micro-structures, each tailored for specific applications. PVC honeycomb fill pack in cooling tower can be selected for direct replacements, performance enhancements, and compatibility with different water conditions. Each fill type has unique performance attributes that assist in choosing the right one based on factors like heat loads, flow rates, water quality, and horsepower needs.

Features of Honeycomb Filler Cooling Tower Packing

- Greater Cooling Capacity: Provides superior cooling performance within a compact space.

- Low-Clog Designs: Engineered to minimize clogging and maintenance issues.

- Versatile Designs: Available in both bottom-supported and hanging configurations.

- FM Approval: Options available that meet Factory Mutual (FM) standards.

- Crossflow and Counterflow Designs: Suitable for various cooling tower setups.

- Integral Louvers and Eliminators: Offered in crossflow designs to enhance efficiency.

- High-Temperature Designs: Capable of withstanding elevated temperatures.

- Single-Piece, Full-Height Counterflow Designs: Streamlined for enhanced performance.

Applications of Honeycomb PVC Fillers

- Inclined Honeycomb Fills: Commonly used for precipitation and degritting in both new constructions and reconstruction projects.

- Water Inlet Degritting: Effective for treating water before entering the cooling system.

- Domestic Water Precipitation: Suitable for municipal water treatment processes.

- Sewage/Waste Water Precipitation: Efficient in treating wastewater.

- Oil Eliminators: Designed to remove oil contaminants from water.

- Biochemical Treatment: Utilized for treating industrial organic wastewater and municipal wastewater.

- High Load Biofilters: Optimized for heavy biological loads.

- Tower Biofilters: Used for filtration in cooling tower applications.

- Submerged Biological Filters: Suitable for submerged treatment processes.

- Microbial Carriers for Biological Rotating Discs: Enhances biological treatment efficiency.

Technical Specifications

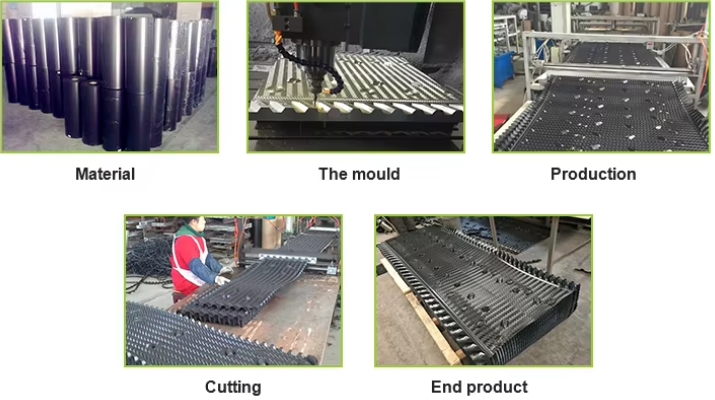

- Material: High-Quality PVC, PP

- Design: Honeycomb structure for maximum heat exchange efficiency

- Application: Compatible with various cooling tower systems

- Maintenance: Designed for easy cleaning and long-term service

Why Choose Our Honeycomb PVC Fills?

- Superior Cooling: The intricate honeycomb design maximizes water exposure, significantly improving the cooling process.

- Durable Construction: Made from high-grade PVC, our fills resist corrosion, withstand high temperatures, and offer a long service life.

- Efficient Design: Our fills promote even water distribution, preventing hot spots and ensuring consistent cooling.

- Low Maintenance: The choice of materials and design allows for easy cleaning and minimal upkeep, contributing to overall operational efficiency.

Enhance Your Cooling Systems

Invest in our Honeycomb PVC Fills to experience unmatched cooling efficiency, durability, and consistent performance.