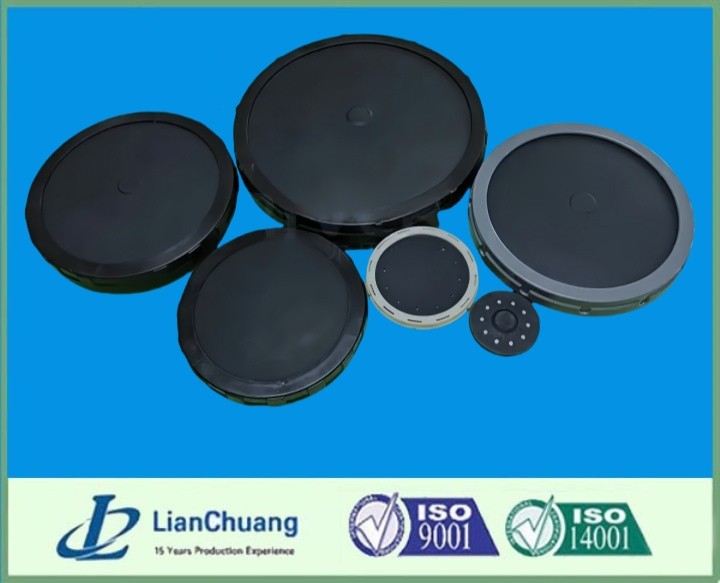

Product Description

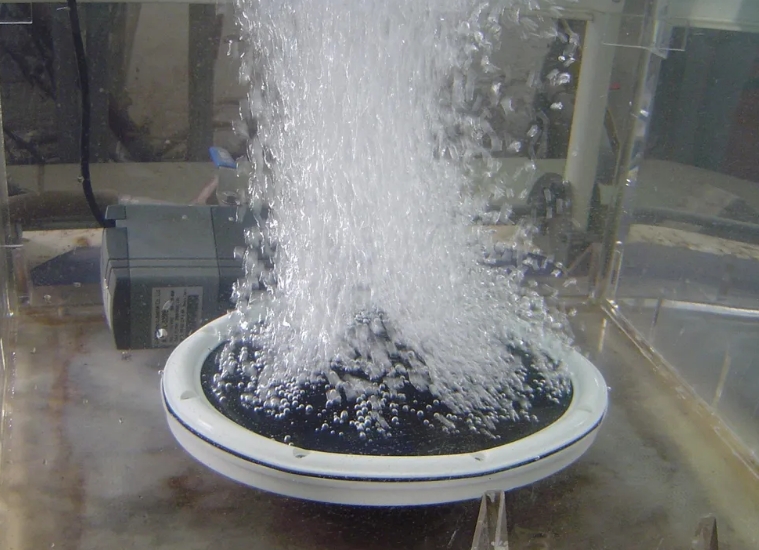

The EPDM fine bubble membrane disc diffuser is engineered with a unique split pattern and slit design, allowing for the dispersion of extremely fine, uniform bubbles that significantly enhance oxygen transfer efficiency. This advanced design ensures high-performance aeration for a variety of wastewater and environmental applications. With an integrated, highly effective check valve, the aeration zones can easily be switched on or off, making it perfect for air-on/air-off operations.

Key Features of EPDM Fine Bubble Disc Diffusers:

- Energy-Efficient and Cost-Effective Design: The EPDM membrane disc diffuser is built with an energy-saving design that reduces operating costs. It offers low installation costs, high reliability, and exceptional performance in both intermittent and continuous aeration processes, making it an ideal choice for wastewater treatment plants, lakes, and ponds.

- Optimized Oxygen Transfer Efficiency: The dense perforation design of the diffuser helps to efficiently transfer and utilize oxygen, improving the overall aeration process. By adjusting the drilling patterns—such as slot length, distance, and density of perforations—users can optimize the aeration system to meet specific working pressures and maximize oxygen dissolution.

- Robust Material Selection: The fine bubble diffuser is made from durable materials designed to withstand the chemical and biological challenges of wastewater treatment, including exposure to a wide range of temperatures (from 0°C to 100°C).

- Uniform Bubble Distribution: The diffuser is designed to release fine bubbles, typically between 1 and 3mm, which are uniformly distributed throughout the water column. This efficient distribution ensures optimal oxygenation for biological processes such as the breakdown of organic material by microorganisms.

- Prevents Liquid Backflow: The structure of the membrane disc diffuser features a built-in mechanism to prevent reflux. When the air supply is turned off, the membrane falls over the diffuser orifice, closing it and preventing liquid from flowing back into the aeration system, functioning similarly to a check valve.

- Advanced Punching Technology: With over 5,500 perforations for DN200 models, 6,300 for DN215, and more than 9,000 for DN260, these disc diffusers ensure maximum air distribution. The small, highly precise perforations and air deflector diameter (0.5 cm) optimize the membrane's opening rate (up to 99.9%) for improved oxygenation and reduced ventilation resistance.

- High-Pressure Injection Molding: Our diffusers are produced using advanced high-pressure injection molding technology. This ensures superior product quality, longevity, and precision manufacturing.

- Compact Structure and Uniform Gas Distribution: The EPDM fine bubble diffuser features a folded-concave structure that enhances sealing performance, preventing dislodging even when air flow is high. Additionally, a guide ring and six air distribution grooves ensure uniform aeration throughout the system.

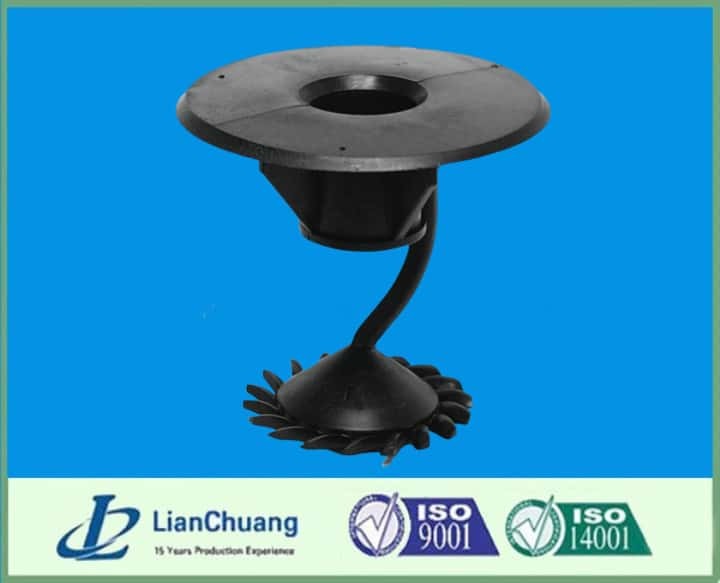

Aeration System Configuration:

The entire aeration system includes bubble diffusers, gas distribution pipes, tees, elbows, regulators, connectors, and cleaning devices. Typically, the gas distribution pipeline is arranged in a circular pattern, with the number of diffusers depending on the required air capacity and the size of the pond or treatment tank. The diffuser and gas pipeline are connected using G3/4 threaded connections, with the base having an internal thread to secure it in place.

Installation Instructions:

- Install the Regulator: Secure the aeration system regulator to the bottom of the pond or tank using expansion bolts.

- Connect Gas Pipeline: Attach the gas pipeline to the regulator using brackets or hoops, and adjust for proper positioning.

- Test System Before Use: To prevent leaks, test the aeration system with water (ensure the water level is at least 10 cm above the diffuser) before powering on the system.

- Complete Installation After Construction: Install the aeration system after the main construction work is complete, ensuring no damage to the equipment.

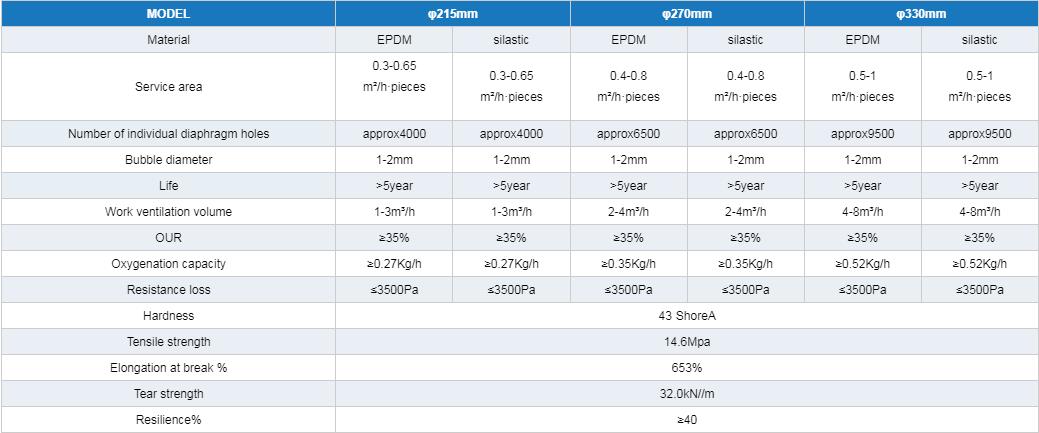

Speicifications of EPDM Fine Bubble Diffusers:

Applications of EPDM Fine Bubble Diffusers:

- Municipal wastewater treatment: Efficient aeration for biological treatment processes.

- Industrial wastewater treatment: Optimal oxygenation for industrial effluent treatment.

- Clean water treatment: Dissolving oxygen in clean water for various purification processes.

- Sludge stabilization: Enhanced aeration for sludge digestion and stabilization.

- Wastewater ozone diffusion: Ozone distribution for advanced water treatment applications.

- Fish pond aeration: Providing oxygen for fish farming and aquatic environments.

- Aeration of lakes and streams: Improving water quality and oxygen levels in natural water bodies.

With the EPDM fine bubble membrane disc diffuser, you get an energy-efficient, durable, and highly effective aeration solution that enhances oxygen transfer and optimizes wastewater treatment processes. Let us help you choose the right diffuser technology to match your aeration requirements and compressor specifications.