Product Description

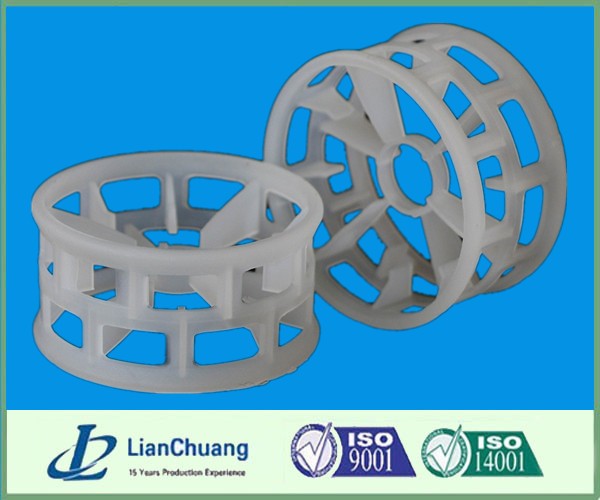

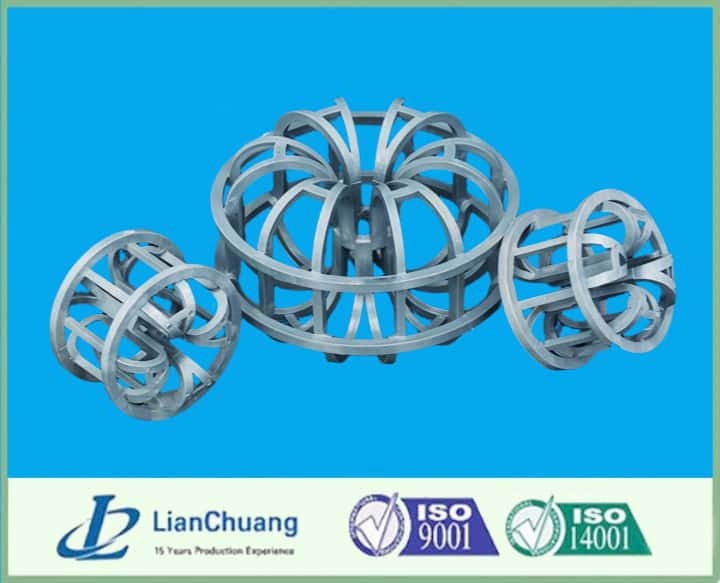

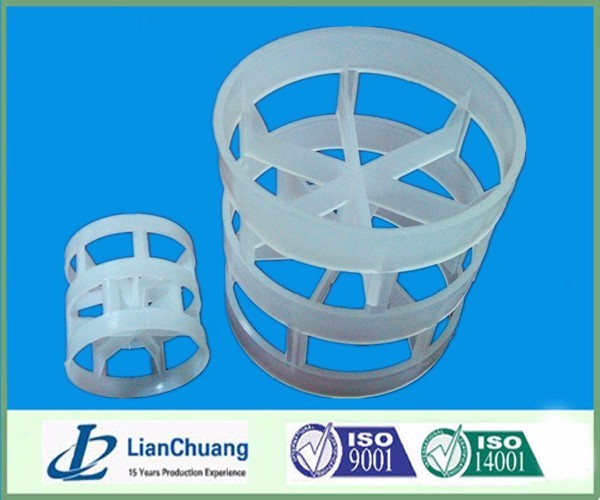

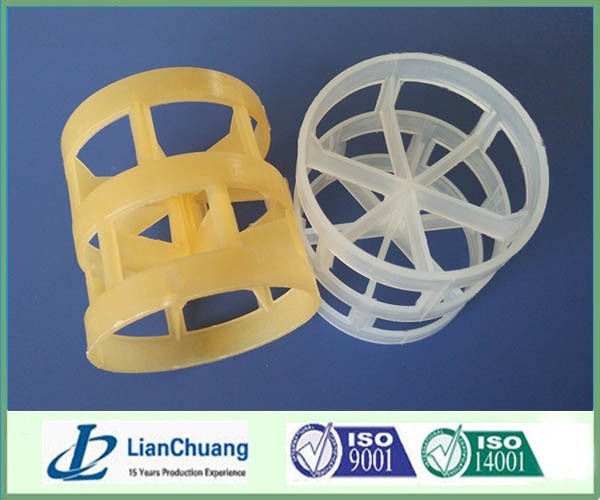

Plastic beta ring also called?β-ETA Packing Ring is original invented by Koch-glistch company. Its structure is similar as plastic cascade ring, but not only attract cascade mini ring's low aspect ratio's advantage, but also increase inner circle in the packing's middle position.Therefore, it is an excellent tower packing.

Plastic beta ring random packing providing further improvement over the CMR packing. The strategic, patented size and placement of the slots and tabs provide an extremely effective use of packing surface area. The variation in the length of the internal tabs ensures high efficiency and optimal distribution. The result is uninterrupted flows of gas and liquid while providing additional drip points to enhance liquid film surface renewal for improved mass and heat transfer.?plastic beta ring packing, β-ETA Packing Ring is particularly well suited forapplications where low pressure drop and high liquid handlingcapacity is important.

Feature:

1. High vapor capacity and low pressure drop

2. Lower pressure drop than pall rings and saddles

3. High efficiency

4. High liquid handling capacity

5. Low liquid hold-up minimizes column inventory and liquid residence time

Application:

1. Absorption and stripping service

2. Air and water coolers in air seperation plants

3. Water treatment

4. Liquid/liquid extraction

Beta Ring Packing Specification:

Diameter(mm) | Void age fraction | Bulk Weight |

25 | 94 | 53kg/m3 3.3ib/ft3 |

50 | 94 | 54kg/m3 3.4ib/ft3 |

76 | 96 | 38kg/m3 2.4ib/ft3 |

Material: Plastic beta ring can be made of polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chloridized polyvinyl chloride (CPVC) and polyvinylidene fluoride (PVDF)