Product Description

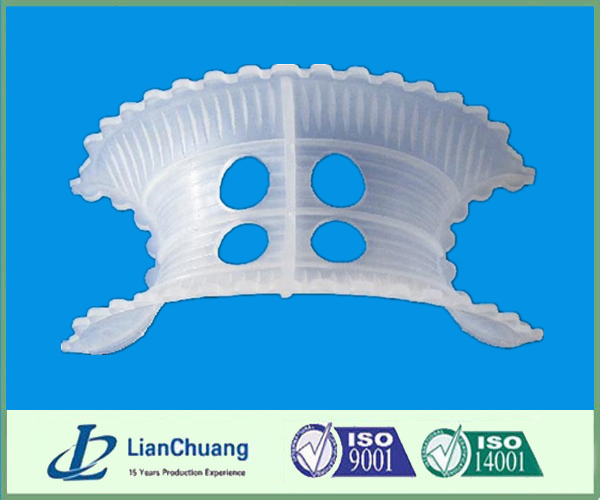

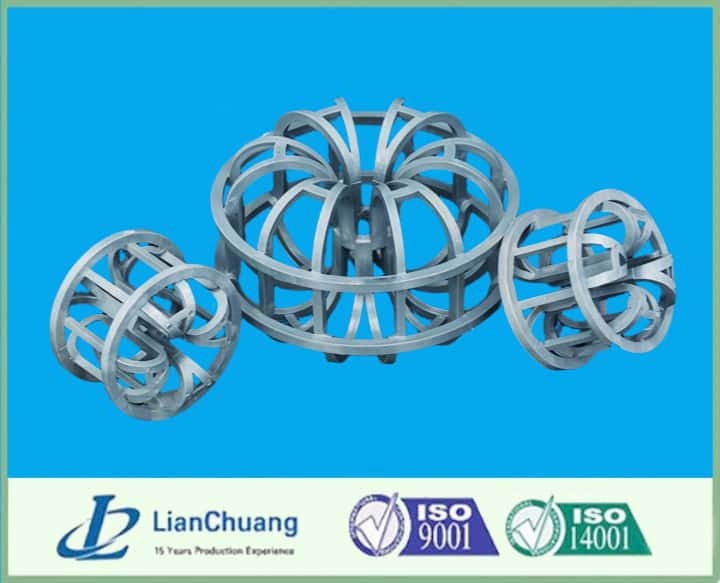

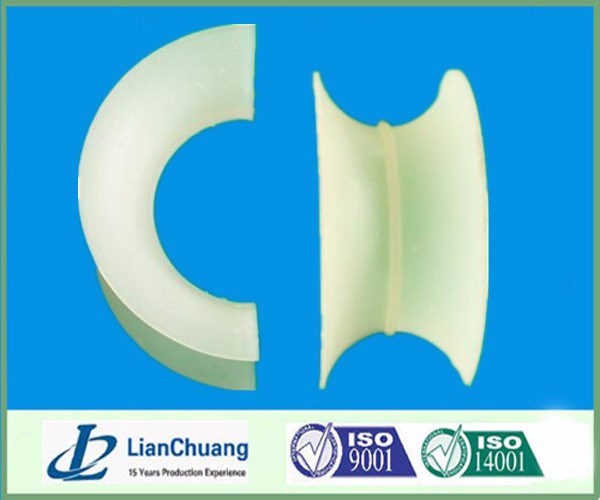

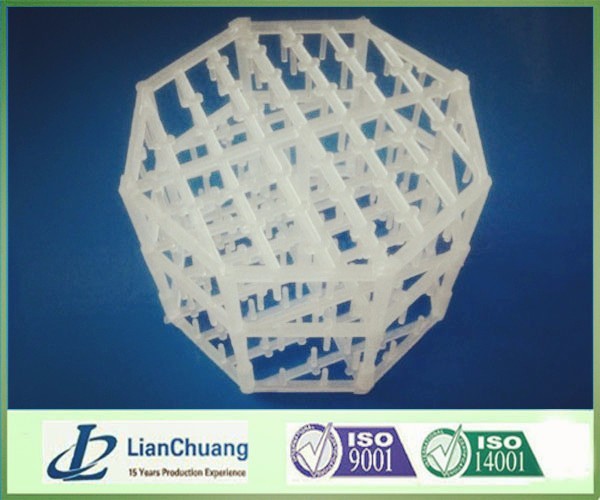

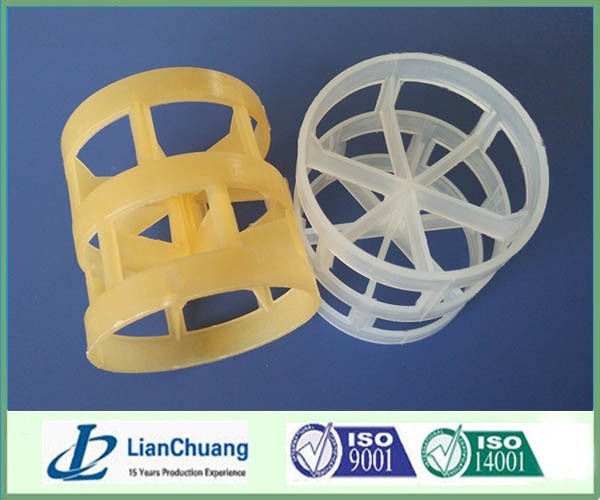

Plastic Super Saddle Rings are are the improved version of the original saddles. They are designed to provide enhanced internal gas and liquid distribution. The unique scalloped edge is the key to the product's high performance in terms of higher capacity and improved rates of mass transfer when compared to traditional plastic saddles. It also serves to overcome the problem of nesting that is commonly encountered with ordinary saddles. It's material could be PE, PP, RPP, PVC, plastic super saddles's economical and has versatile industry standard with well-known performance characteristics. P;astoc si[er saddles' high-performance tower packing materials widely used in gas-liquid and liquid-liquid separation processes. Made from high-quality plastic materials, they feature excellent mass transfer efficiency and good mechanical strength. As an essential component in industrial tower equipment, Plastic Super Saddle Rings play a critical role in processes such as gas absorption, distillation, and adsorption. Their unique saddle-shaped design significantly increases the gas-liquid contact area, improving the efficiency of mass transfer and separation.

Key Features

- High Mass Transfer Efficiency: The unique design provides a large surface area and excellent gas-liquid distribution, significantly enhancing mass transfer efficiency.

- Outstanding Corrosion Resistance: Made from Polypropylene (PP), Polyethylene (PE), and Polyvinyl Chloride (PVC), these saddle rings offer excellent resistance to acids, alkalis, salts, and organic solvents.

- Good Mechanical Strength: Manufactured with high-quality plastic materials, providing strength to withstand high fluid velocities and impacts.

- Low Pressure Drop and Excellent Fluid Distribution: The design ensures uniform gas-liquid distribution and low-pressure drop, improving separation efficiency.

- Strong Anti-Clogging Ability: The design helps prevent the accumulation of particles and sediments, improving operational stability.

- Lightweight and Easy Installation: Plastic Super Saddle Rings are lightweight, easy to transport and install, reducing the overall load on tower equipment.

Applications

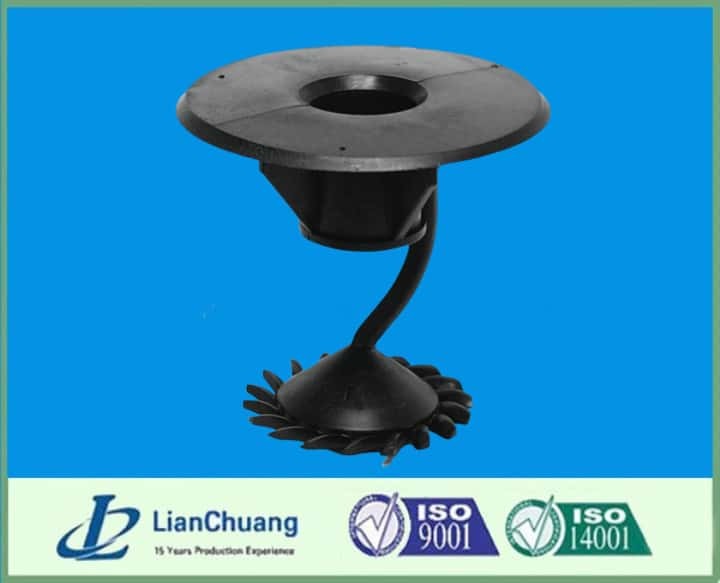

- Chemical Industry: Used in chemical reaction towers, absorption towers, distillation towers, and other equipment, for gas absorption, distillation, extraction, and separation processes.

- Oil and Gas Industry: Applied in oil and gas separation, gas desulfurization, and other processes, improving separation efficiency and reducing costs.

- Environmental Protection and Wastewater Treatment: Used in exhaust gas treatment and wastewater treatment, improving gas-liquid contact efficiency and removing harmful pollutants.

- Food and Pharmaceutical Industry: Suitable for gas separation and solvent recovery processes, ensuring high efficiency and purity in the separation process.

Technical Specifications

D*H*T

Number per m?

Bulk density

Surface area

Free volume

Factor

(mm)

PCS

(kg/m?)

(m?/m?)

(%)

(m-1)

25*12.5*1.2

97680

102

288

84.7

473

38*19*1.2

25200

63

265

95

405

50*25*1.5

9400

75.2

250

96

332

76*38*2.6

3700

59.2

200

97

289

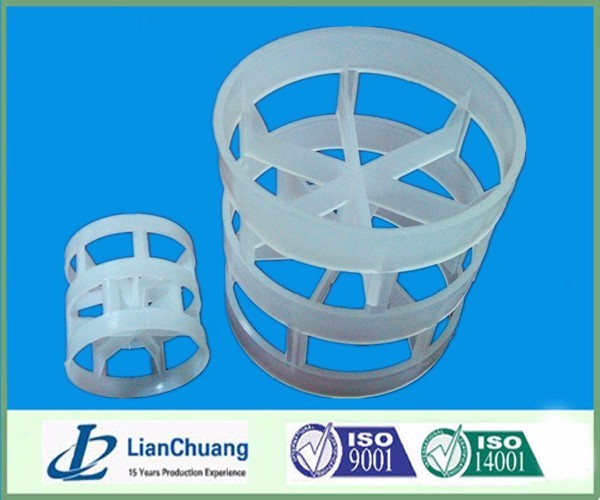

- Material: Polypropylene (PP), Polyethylene (PE), Polyvinyl Chloride (PVC), and other engineering plastics

- Size Range: Common sizes include 25mm, 38mm, 50mm, etc.

- Surface Area: Large surface area design to enhance gas-liquid contact efficiency

- Temperature Range: -20°C to +100°C

- Pressure Rating: Capable of withstanding up to 1.0 MPa (depending on material and design)

- Corrosion Resistance: Resistant to acids, alkalis, salts, and organic solvents

- Bulk Density: 0.3–0.6 kg/L (depending on packing size)

Packaging and Shipping

Plastic Super Saddle Rings are packaged to ensure protection during transportation, preventing compression or damage. The packaging is moisture-proof to maintain product quality during storage. Bulk orders can be accommodated, with customized packaging available upon request.

Conclusion

Plastic Super Saddle Rings, with their high mass transfer efficiency, excellent corrosion resistance, and reliable mechanical strength, are an indispensable component in gas-liquid and liquid-liquid separation equipment. Whether in the chemical, oil and gas, environmental protection, or food and pharmaceutical industries, Super Saddle Rings offer excellent separation performance, helping customers increase operational efficiency, reduce production costs, and promote efficient and environmentally friendly industrial processes.