Product Description

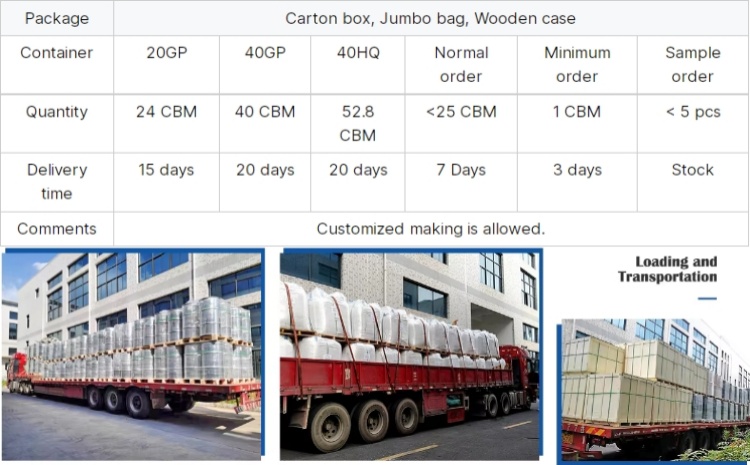

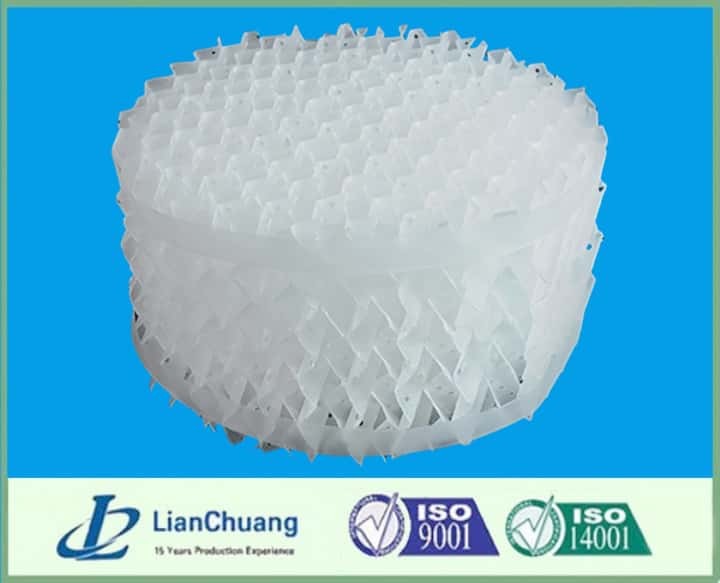

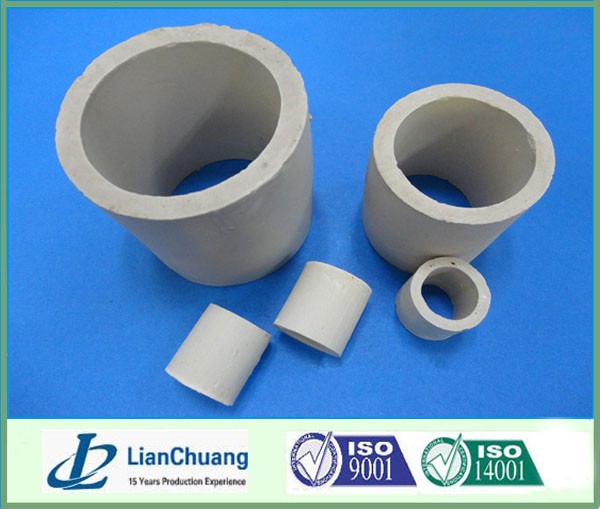

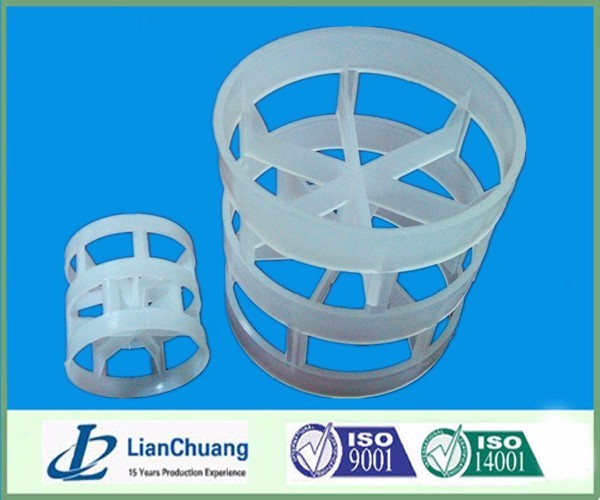

Raflux Rings, also known as Pall Rings, are a type of random tower packing widely used in industrial applications for mass transfer processes. These rings are second-generation tower packing materials, evolved from the traditional cylindrical rings, and are known for their open structure. The design of raflux rings promotes regular fluid flow through the packing while reducing pressure drop, which enhances the overall efficiency of the system. They are available in various materials such as ceramics, plastics, and metals, making them versatile for different industrial needs. Due to their design and functionality, Raflux Rings are one of the most commonly used packing materials in industries like chemical processing, environmental control, and gas absorption.

Features of Raflux Rings

- High Mass Transfer Efficiency: Raflux Rings are designed to provide a high surface area, allowing for efficient gas-liquid contact and improved mass transfer rates. This makes them suitable for processes requiring high separation efficiency.

- Low Pressure Drop: One of the key advantages of Raflux Rings is their ability to reduce pressure drop compared to traditional cylindrical rings. The open structure facilitates regular fluid flow, ensuring minimal resistance and better energy efficiency during operations.

- High Flux: Raflux Rings are designed to handle high flow rates, making them capable of managing large volumes of gases and liquids. This high flux is particularly beneficial in large-scale industrial processes, where efficient processing of materials is critical.

- High Gas Velocity: The rings, especially those made from plastic or metal, are capable of handling high gas velocities without sacrificing separation efficiency. This feature makes them ideal for demanding applications where high gas flow rates are essential.

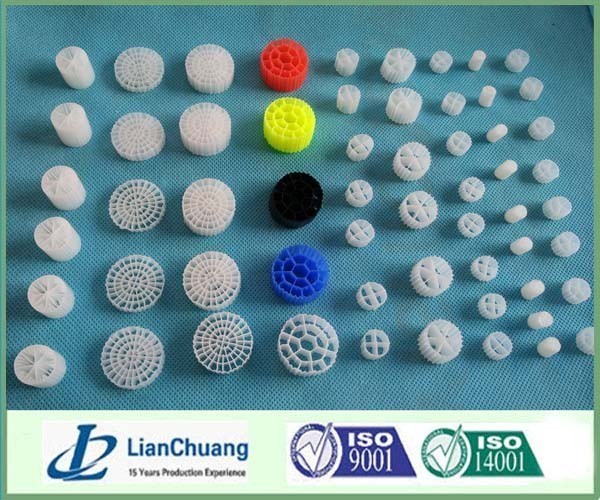

- Variety of Materials and Sizes: Raflux Rings are available in a wide range of materials, including ceramics, polypropylene, polyethylene, and metals. The variety of materials allows for customization based on specific process requirements, such as chemical resistance, temperature tolerance, and mechanical strength.

- Improved Efficiency Compared to Cylindrical Rings: Evolved from traditional cylindrical rings, Raflux Rings feature an open structure that improves fluid flow and reduces pressure drop while maintaining the same surface area for gas-liquid interaction. This results in improved operational efficiency and better process control.

Specifications of Raflux Rings

Raflux Rings are available in three primary materials: metal, plastic, and ceramic. Each material is chosen based on its unique properties that cater to different industrial applications, environments, and operational requirements. Below is a detailed explanation of the characteristics of each material, followed by a specifications table that outlines their dimensions and other key properties.

Plastic Raflux Rings

| D*H*T | Number per m³ | Bulk density | Surface area | Free volume | F factor |

| (mm) | PCS | (kg/m³) | (m²/m³) | (%) | (m-1) |

| 16*16*1.1 | 112000 | 141 | 274 | 91 | 249 |

| 25*25*1.2 | 53500 | 150 | 175 | 90 | 239 |

| 38*38*1.4 | 15800 | 98 | 115 | 89 | 220 |

| 50*50*1.5 | 6500 | 74.8 | 112 | 90 | 154 |

| 76*76*2.6 | 1930 | 70.9 | 73 | 92 | 94 |

Material: PP,RPP,PE,PVC,CPVC,PVDF,etc.

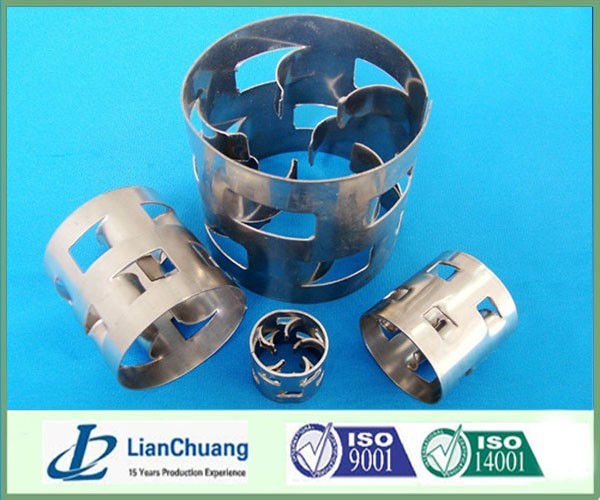

Metal Raflux Rings

| Sizes | Bulk density | Number | Surface area | Free volume |

| (mm) | (kg/m3) | (per m3) | (m2/m3) | (%) |

| 16×16×0.3 | 345 | 201000 | 346 | 95.5 |

| 25×25×0.3 | 214 | 51000 | 212 | 96.2 |

| 38×38×0.4 | 193 | 15000 | 145 | 96.7 |

| 50×50×0.5 | 182 | 6500 | 106 | 97.5 |

| 76×76×0.6 | 142 | 1830 | 69 | 97.4 |

| 89×89×0.7 | 145 | 1160 | 62 | 97.1 |

Material:Carbon Steel; Stainless Steel 304, 304L, 410, 316, 316L, etc.

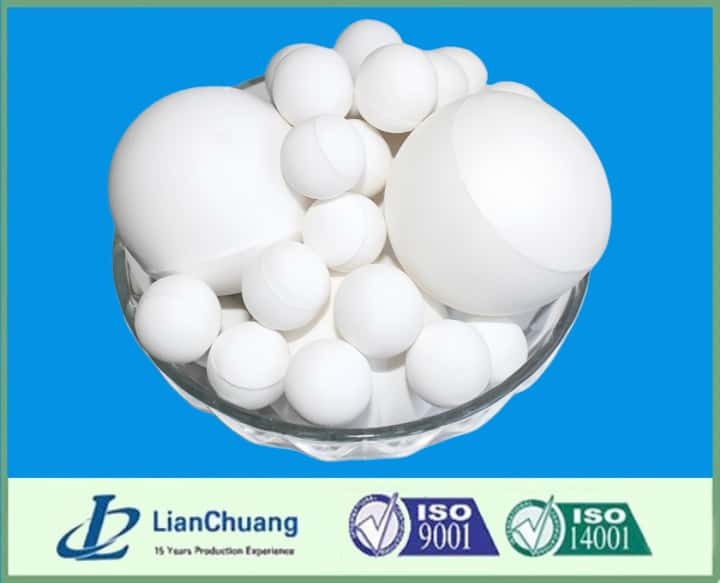

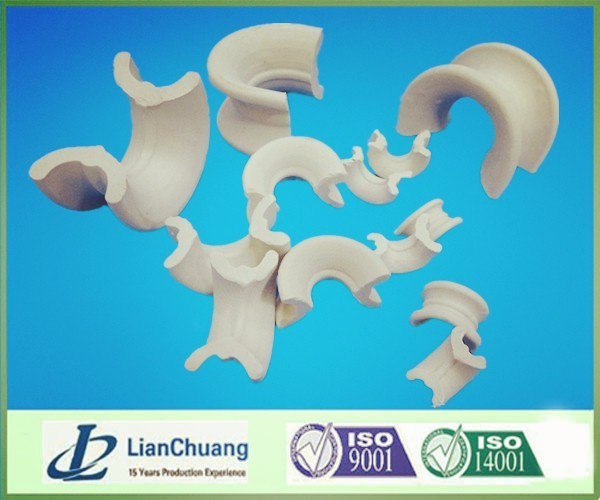

Ceramic Raflux Rings

| Diameter (mm) | 25 | 38 | 50 | 80 |

| Thickness (mm) | 3 | 4 | 5 | 8 |

| Bulk density (kg/m3) | 650 | 620 | 600 | 550 |

| Number (PCS/m3) | 53,500 | 13,400 | 6,800 | 1,950 |

| Surface area (m2/m3) | 210 | 150 | 120 | 75 |

| Free Volume (%) | 73 | 75 | 78 | 80 |

Applications of Raflux Rings

- Absorption: In gas absorption processes, Raflux Rings facilitate efficient gas-liquid interaction, making them ideal for capturing and dissolving gases into liquids in applications such as air pollution control and chemical manufacturing.

- Scrubbing: Raflux Rings are commonly used in scrubbers to remove harmful particulates and gases from industrial exhaust streams. Their design allows for efficient mass transfer, helping in the removal of contaminants from gas streams.

- Stripping Services: In stripping processes, where volatile components are removed from liquids, Raflux Rings provide high efficiency by maximizing contact between the gas and liquid phases, ensuring effective separation.

- Separation Processes: Raflux Rings are widely used in various separation applications, including distillation, solvent recovery, and liquid-liquid extraction. Their high surface area and efficient mass transfer properties make them ideal for separating different components in mixtures.

- Plastic-Packed Columns: Raflux Rings often used in columns that require resistance to corrosion and chemical attack, such as in the chemical processing industry.

- Cooling Tower Packing: Due to their high flux and low pressure drop characteristics, Raflux Rings are also used as packing material in cooling towers. Their design allows for efficient heat and mass transfer, improving the cooling process in industrial operations.

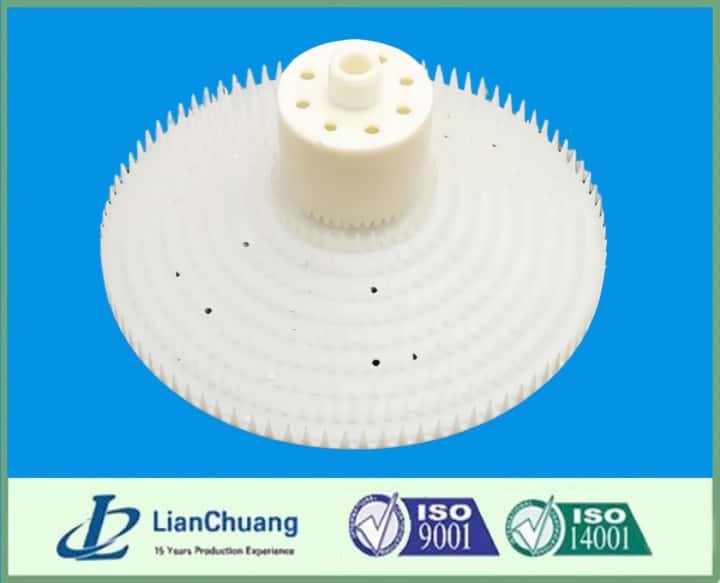

Package & Delivery