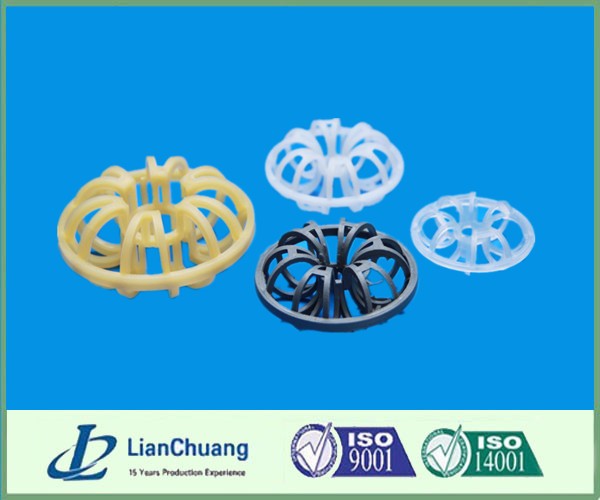

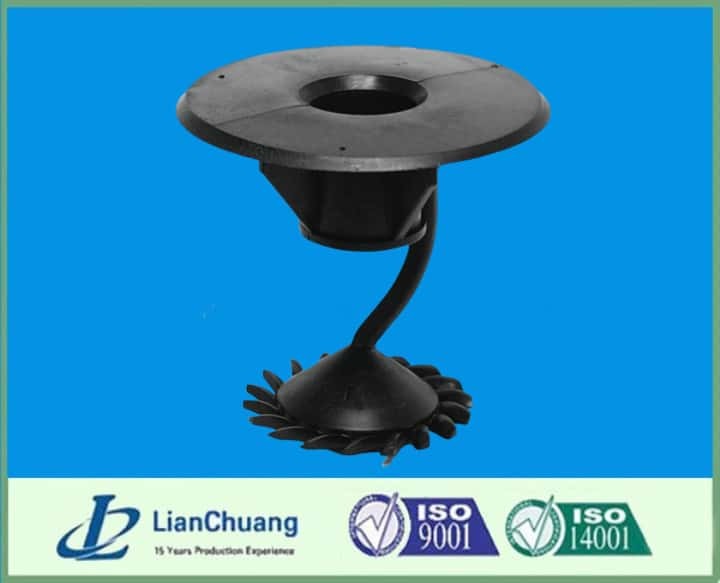

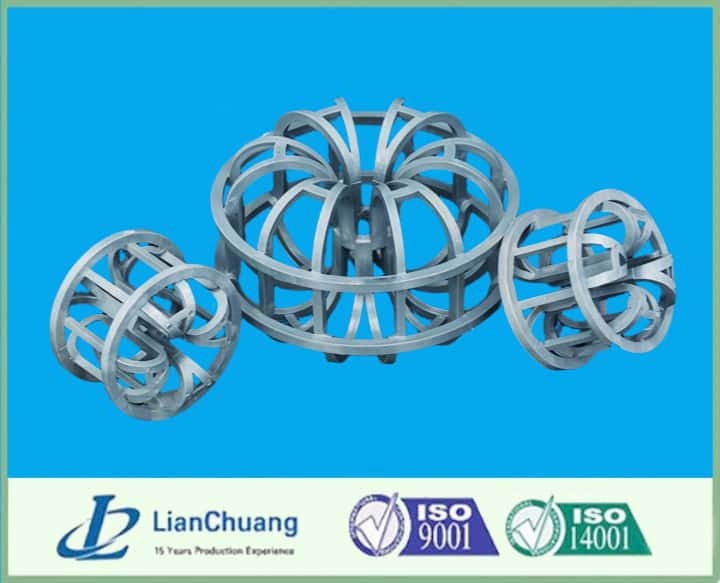

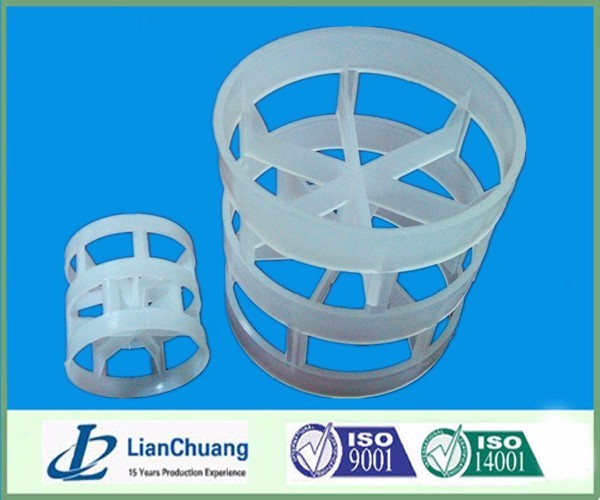

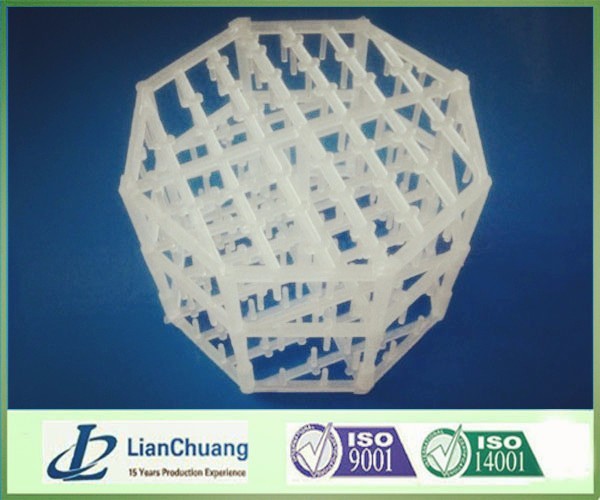

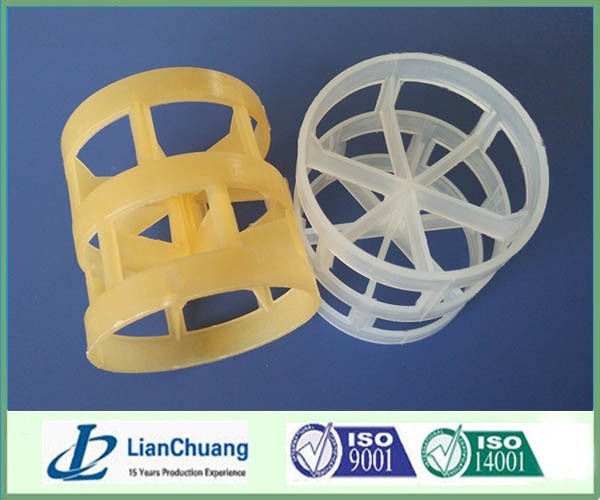

Product Description

tellerette packing is developed by Dr. A. J. Teller in the 1950s, its a filamentous shape random packing shape. The tellerette packing usually made in plastic material. hdpe pp pvc pe cpvc tellerette packing specially designed interstitial points of this packing ring are instrumental in raising liquid surface area which is advantageous for better mass transferring purpose. This special structure make it dramatically more efficient than conventional packing material for mass transfer, heat transfer, and particulate collection. As tellerette packings has excellent features of mass and heat transfer efficiency for gas absorption, air conditioning, etc., it has been used as packing of high corrosion resistance and low pressure drop with extensive application for Gas Absorber, Scrubber,Cooling Tower, Deaerator, Reactor and other gas-liquid contact systems.

Feature of tellerette packings:

1. Big Effective contacting surface area

2. Easy operation

3. More contacting points in packed bed

4. Evenly liquid distribution

5. Excellent removal efficiency

6. Lower pressure drop to reduce operating costs

7. High open area design for minimal fouling

Tellerette Packing Applications:

1.Chemical industry: H2S, HCl, Cl2, HF, NOX elimination, organic solvents recovery

2.Pulp industry: Black/white liquor oxidation

3.Water purification: Ammonium, trihalomethane, trichloroethylene stripping

4.Sewage treatment: Deodorization

5.H2SO4/Ammonium sulfate industry: SO2, SO3, NH3, Absorber, Scrubber

6.Soda industry: Chlorine drying tower

7.Iron & steel/coke industry: COG desulfurization tower, COG middle/light oil collector, gas cooling tower

8.Oxygen plant: Air cooling

9.Thermal power: Flue gas desulfurization

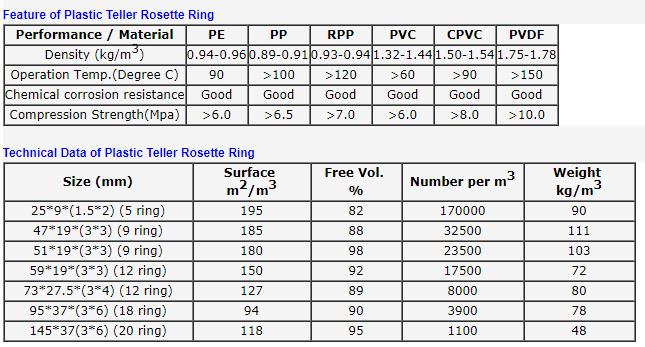

Note: Our factory can arranged production for tellerette packing different materials, such as polyethylene(PE), polypropylene(PP), reinforced polypropylene(RPP), polyvinyl chloride(PVC), chlorinated polyvinyl chloride(CPVC.and polyvinyllidene fluoride(PVDF).